Video: 3D Printer Cooks Up Blood Vessels

July 17, 2012

Additive manufacturing and 3D printing technologies are definitely being used more frequently for manufacturing applications as a cheaper, more efficient way to produce working prototypes. Lower-cost offerings are taking hold among do-it-yourself hobbyists and aspiring inventors as a means of cost-effective personal manufacturing. Now we're starting to see a wave of new innovative use cases as 3D printing takes hold in the medical field.

One new interesting example is in the field of regenerative medicine, specifically as part of an effort to build lab-grown organs out of a patient's own cells. Scientists can create small samples of tissue in the lab, but one of the longstanding challenges to making human-sized organs involves designing a vasculature, the blood vessel plumbing system that delivers nutrients and removes waste from the cells inside a tissue mass. Without such an infrastructure, interior cells suffocate and die.

One solution that has gained attention is to "print" cells for the vasculature, layer by layer, leaving openings for the blood vessels as required. Yet even this approach has had its share of setbacks. When blood is pumped through the vessels, the seams get pushed apart.

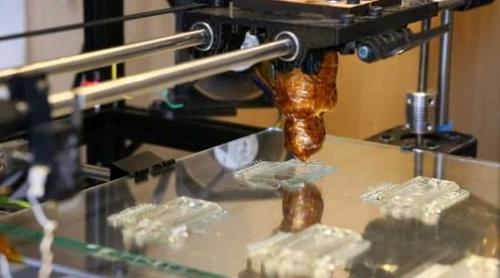

A team of bioengineers from the University of Pennsylvania and MIT took inspiration from a visit to a Body Worlds exhibit and decided to address the problem in a different way. They've applied the open-source RepRap 3D printer as a foundational technology solution and made templates of blood vessel networks out of sugar.

According to Jordan Miller, a bioengineering post-doc at the University of Pennsylvania, the researchers design the blood vessel architecture on a computer and feed the design to the RepRap printer, which builds the walls that function as a stabilizing mold layer by layer, drawing sugar across the mold in filaments. Once the sugar hardens, the researchers pour cells (in this case, liver cells) suspended in a gel into the mold surrounding the filaments. After the gel solidifies, the networks are encased in a block of cells, and the sugar can be dissolved, leaving a functional vascular network behind. Miller is working on the research along with Christopher Chen, the Skirkanich Professor of Innovation in the Department of Bioengineering at Penn; other members of Chen's lab; and colleagues from MIT.

Testing has shown the 3D printing solution to be a success. According to the researchers, the cells survived and improved their function when the sugar-based vascular networks were in place. They also said the RepRap 3D printer makes testing new vascular architectures quick and inexpensive, and the sugar is stable enough to ship finished networks to labs that don't have 3D printers of their own.

Related posts:

About the Author(s)

You May Also Like