Fujitsu Labs Addresses 3D Parts Reuse

June 7, 2012

Manufacturers of all types regularly try to leverage existing CAD models as a basis for new parts to try to avoid starting each part design from scratch. By retrieving and using models with shapes similar to existing models and which incorporate already proven design know-how, companies can enjoy the benefits of reuse -- shortened design cycles, less rework, and as a result, less costly development cycles.

Despite the clear benefits of reusing part models, companies are still struggling to do so effectively, particularly on a global basis, when parts models are stored in different systems, with different naming conventions, maybe even using different languages.

Fujjitsu Labs Limited, in partnership with Fujitsu Research and Development Center Co., decided to address the problem of "global shape retrieval" and are collaborating on new technology to help engineers retrieve partially similar models from stored 3D CAD models. Existing 3D CAD model retrieval technology is limited, according to Fujitsu researchers, because it performs either text-based retrieval, requiring people to invoke part names and other keywords, or global shape retrieval, a capability for retrieving CAD models based on their global shape.

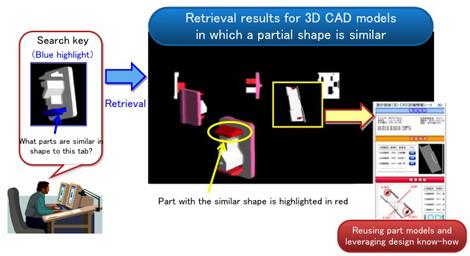

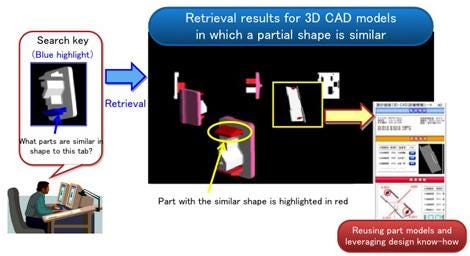

Both technologies hamper manufacturers' ability to reuse 3D CAD models of parts because they can't detect 3D CAD models with partially similar shapes, according to Fujitsu researchers. That's where the new technology comes in. Fujitsu's technique, still a work in progress, analyzes the elements composing a 3D CAD model, including the positional relationship between different surfaces, and uses it to automatically segment the model into distinctive parts -- for example, protruding shapes -- which make it easier to find a match and facilitate retrieval. In addition, the new technology will automatically extract shape features such as concave and convex surfaces from the segmented parts and use those to compare to the shape features of the search key, further aiding in part retrieval.

Fujitsu researchers say as long as the shapes are similar, the search criteria will determine the similarity and locate the part, even if the orientation, size, or position of the models vary. A designer or engineer simply specifies a shape to be used as a search key, and via the automatic segmentation process, similar parts are retrieved from the database using the global shape retrieval capabilities. Finally, the technology also allows the designer-specified search key and similar-shaped 3D CAD models to be viewed in a virtual 3D space for comparison, using color-coded highlighting to bring visibility to similar parts.

In initial testing and research, officials say the new technology successfully segmented 10,000 3D CAD models into approximately 100,000 parts, and a search key retrieved 3D CAD models containing similar shapes in seconds -- a metric researchers say makes the technology a prime candidate for real-world use. As a result, Fujitsu plans to pursue commercialization of the technology and it will incorporate it into its PLEMIA design information management system by the year's end.

Related posts:

About the Author(s)

You May Also Like