3D Printing Super-Hard Metal Matrix Composites

November 7, 2014

High-hardness ferrous metal matrix composite (MMC) parts have been produced in a one-step 3D-printing process using a new nanosteel powder. The NanoSteel Company worked with an unnamed process development partner to adapt its nanosteel powders to laser sintering, producing a 99.9% dense, crack-free part with wear resistance it says is comparable to M2 tool steels made with conventional subtractive manufacturing.

NanoSteel is a maker of proprietary nanostructured steel alloy materials, including sheet metal, powder metals, surface coatings, and foils. It serves applications in extreme industrial environments, and in the oil & gas, mining, and power industries, as well as automotive. By developing this new high-hardness powder metal alloy for additive manufacturing (AM) in a cost-efficient, one-step process, the company says it hopes to extend its reach into areas that currently use ceramic and non-ferrous MMCs, such as cutting tools, pumps and bearings for the mining, energy, tooling, and transportation industries.

In AM processes such as laser sintering, materials are put through very high stresses due to high cooling rates so cracking occurs easily in hard materials, Harald Lemke, general manager of engineered powders for NanoSteel, told Design News. The company and its development partner worked to optimize the processing of a proprietary NanoSteel alloy with a high volume fraction of borocarbide phases, using a powder bed fusion process. The result was MMC parts made of a wear-resistant material with a small, uniform microstructure, and a density higher than that of cast steel at 99.9%. Hardness values are 1,000 HV, or 61.91 HRC (Hardness Rockwell C), while some part densities are even above 99.99%, Lemke said. No post-processing, such as hot isostatic pressing or any further heat treatment was required, reducing production costs.

In general, nanosteels have a different chemical composition from most steels. This makes it possible to use them for producing an MMC directly from steel without any additional processes, said Lemke. "Other producers of nanosteels make nano-sized powders," he told us. "But NanoSteel makes micron-sized powders that fit easily into normal powder metal processes. The economics are therefore different: our powders provide complexity of the structure for free, just as additive manufacturing provides complexity of the part for free." Because the new process has such a huge cooling rate in AM, it's possible to do more refining of the structure than in subtractive manufacturing, so the company's nanosteels lend themselves more readily to AM.

Normally, a more ductile material is not very hard, and a harder material cracks.Because NanoSteel can make alloys with a uniform small grain structure, both qualities are possible in the same part. This combination is needed for industrial uses, such as agriculture, mining, oil & gas, tooling, and bearings, since so many of those applications use iron-based materials but are extremely limited in materials that are both reliable and cost-efficient to process. "When you deal with tungsten carbide or other hard materials it costs a fortune to grind them, and changes in design and shapes are very difficult to accomplish," said Lemke. "We want to turn what's currently hand craftsmanship into an industrial process."

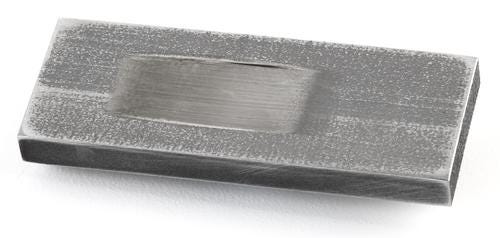

At present, the effort is still in the proof-of-concept stage, and has produced a simple wear coupon measuring 3 inch x 1 inch x 0.25 inch. The next step is to make more complex shapes and broaden the property sets of materials. This stage has already begun, and the company expects to finish this step next year. After that, parts will be put into field trials, said Lemke.

NanoSteel is also a member of the Lightweight and Modern Metals Manufacturing Innovation (LM3I) Institute team, led by EWI. The federally funded LM3I Institute, established last February, is a consortium of businesses and universities focused on developing lightweight, high-performing metals and alloys that can be commercially produced for defense, aerospace, automotive, energy, and consumer products industries. It includes some of the world's leading aluminum, high-strength steel, and titanium manufacturers, working with universities and laboratories doing R&D in new technology development, including advanced metals manufacturing methods, as well as the design of end-use components made with them.

Related posts:

About the Author(s)

You May Also Like