3D Molding Analysis Software Moves to Smart Design

Software offers upgraded measurement features and the ability to store molding data in cloud.

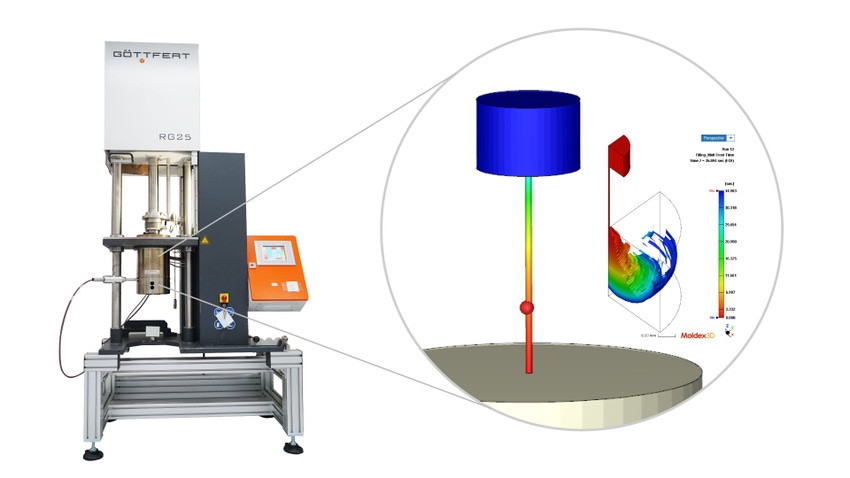

As in other manufacturing and design processes, 3D molding software is benefitting from additional measurement and analysis features as well as the ability to share data online across users. CoreTech System Co., Ltd. has released Moldex3D 2022, its molding analysis software, with reinforced system constructure and improved analysis performance.

These features aim to deliver more accurate molding results for users. CoreTech has also enhanced the software with new services for smart design, smart management, and smart learning that help users achieve seamless design, production integration, and team efficiency.

Moldex3D 2022 has upgraded measurement features to provide timely point and plane measurement for users to track core problems in molding results. Design of Experiment (DOE) analysis wizard can be used to identify key influencing factors and optimize product quality. DOE and Shell analysis are supported on the Linux platform, which can greatly reduce calculation cost, shorten the calculation time and speed up development. Moldex3D Studio also provides versatile API functions to help users build automated analysis, compare simulation results, optimize process, and even realize intelligent integration.

To help users control the two most critical factors, machine and material properties, in the molding process, the software has Machine Characterization Services to capture unique performance and dynamic responses from each molding machine, which are also integrated into CAE analysis to reflect real manufacturing conditions, presenting more accurate simulation results.

The software also incorporates a professional material measurement center with ISO/IEC 17025 certification. It has decades of plastic data measurement technology and previous molding data to construct complete material digital twins, improving prediction accuracy on injection pressure, warpage, and shrinkage.

A SYNC geometry optimization feature supports Design of Experiment (DOE) and can perform geometrical analysis on critical dimensions, understanding the possible defects of molding. The software also has enhanced runner, gate, and cooling wizards. This not only strengthens the design of runners and cooling line systems, but also provides more diverse layouts for different situations, adding design flexibility.

Moldex 3D has optimized mesh generation. This enhances preprocessing, CAD import, mesh functions and geometry healing functions, enabling users to repair geometric defects more easily and improve model quality.

More powerful modeling capabilities include a more complete IC Auto Mesh function, and enable users to freely create advanced packaging, such as CoWoS and InFO types. The software also has the capability to record the entire development process of design and mold trial. These data are uploaded to the cloud system, so team members in different locations can access, share, and reuse simulation data anytime, anywhere. The new version of Moldex3D 2022 also supports user-customized simulation results and report production.

Moldex3D has also launched the MPE digital learning system (Moldex3D Plastics E-Learning), providing professional terminology in the plastic molding industry, knowledge of injection molding machines, and real cases collected from decades of industrial experiences. Tests after each session enable students to validate their learning results.

Spencer Chin is a Senior Editor for Design News covering the electronics beat. He has many years of experience covering developments in components, semiconductors, subsystems, power, and other facets of electronics from both a business/supply-chain and technology perspective. He can be reached at [email protected].

About the Author(s)

You May Also Like