Wireless Gaining Momentum in Remote Monitoring

March 6, 2015

Time was when the term "wireless" only conjured up images of mobile phones and garage door openers.

That's changed. One of today's fastest-growing areas of wireless technology has little to do with cell towers and a lot to do with data. Using wireless chips and accessories, engineers can now extract data from the unlikeliest of places -- pumps, motors, bridges, conveyors, refineries, cooling towers, parking garages, down-hole drills, and just about anything else that can benefit from monitoring. The key is to link a sensor to a wireless card and then broadcast its data via radio to a receiver, eliminating the need for people to climb and crawl and run wires to hard-to-reach places.

Because it's an eminently practical concept, the popularity of wireless monitoring is growing. "Today, our market space is $16 billion for process control sensor networks," said Bob Karschnia, vice president of wireless for Emerson Process Management, which makes products to measure and analyze industrial processes. "But we expect it to go from $16 billion to $32 billion in the next 10 years."

Indeed, engineers are finding that wireless can be a powerful alternative to wired technology in certain applications. Situations that don't lend themselves to easy installation of cabling are prime candidates. "They get to the point where the cost can be so high that they just don't do anything," Karschnia said. "But if they go wireless, they can reduce that cost." In many situations, the wired-or-wireless conundrum is similar to the one faced by consumers deciding whether to use a wireless router or hard wiring in their homes, Karschnia says.

The breadth of today's wireless applications is stunning. Process engineers have employed wireless technology in refinery cooling towers and injection wellheads. Using an IEEE 802.15.4-based sensor networking technology called WirelessHART (Highway Addressable Remote Transducer Protocol), Emerson has helped create steam trap monitoring systems that save refineries $1 million to $3 million a year.

MORE FROM DESIGN NEWS: When Will the Smart Home Really Be Smart?

Similarly, National Instruments has used wireless sensor networks to monitor stresses on aging bridges. By connecting strain gauges to data acquisition nodes and then wirelessly sending data from the nodes to an NI 9792 wireless sensor network gateway, structural engineers have been able to use wireless to monitor the impact loads caused by 18-wheelers and garbage trucks rolling across the bridges. National Instruments says its hardware and software have also been employed to analyze historic structures, check energy consumption, monitor machinery and provide occupancy information in parking garages. "Operators can connect via tablets or smartphones," noted Nick Butler, a group manager of embedded systems at NI, in an email to Design News. "And data can be viewed, shared, or analyzed across devices, the enterprise, or the cloud."

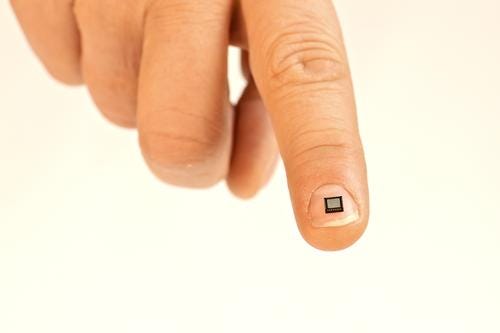

The key to such monitoring lies in the hardware and software. Numerous suppliers make wireless microcontroller boards. Texas Instruments, for example, recently released its SimpleLink ultra-low power wireless microcontroller platform, aimed at delivering low-power wireless connectivity to the Internet of Things. The first products in the family support Bluetooth Smart, 6LoWPAN and Zigbee wireless protocols. Similarly, Microchip Technology now offers a series of modules, called LoRa, for IoT applications and Linear Technology Corp. offers a WirelessHART chip. Known as the LTC5800-WHM , the WirelessHART chip features a low-power radio and an ARM Cortex-M3 32-bit microprocessor. Its processor runs embedded wireless networking software from Dust Networks.

The tricky part, of course, is to make such devices use as little current as possible. TI's SimpleLink accomplishes that with a chip design that can remain in a standby mode, drawing just 1muA, with memory retention and its real-time clock running. Linear Technology's LTC5800-WHM also minimizes current, using less than 10 mA to send and receive data packets.

"By comparison, WiFi systems will use about 100 times as much current," said Karschnia of Emerson. "And a cell phone uses 1,000 times more power."

For remote applications, power delivery is another big challenge. With many wireless applications located in hard-to-reach locales, physical power cables can be a problem. That's why many engineers turn to batteries, with the goal of long life. Most say they want a minimum of 10 years and possibly as many as 20 from a battery, so that maintenance workers don't have to make frequent sojourns to the tops of bridge trusses or cooling towers to swap out a couple of dry cells.

MORE FROM DESIGN NEWS: What Role Will 8-Bit MCUs Play in the IoT?

Makers of lithium thionyl chloride batteries say their technology can supply the long life that wireless engineers seek. Tadiran Batteries, for example, offers lithium thionyl chloride (LiSOCL2) batteries that it says can deliver up to 40 years in certain applications. Tadiran also offers a hybrid LiSOCL2 battery called PulsesPlus that can deliver higher pulses of up to 15A.

Tadiran also offers TLI Series industrial grade Lithium-ion (Li-ion) rechargeable batteries that offer up to 20 years of service life, 5,000 full recharge cycles, and the ability to deliver up to 5 A pulses. These industrial grade rechargeable Li-ion batteries are said to be a good choice for energy harvesting applications, which continually draw tiny pulses of power from the sun or some other source.

MORE FROM DESIGN NEWS: IIoT Top of Mind at Manufacturing Show

"If the product doesn't need long life, then you may not need an industrial grade battery," a Tadiran spokesman told Design News. "But in most remote monitoring applications, long life is critical," he says.

To be sure, not every sensor network needs wireless. Applications with numerous flow, pressure, level and temperature sensors, located within close proximity of one another, can often be better served by wired fieldbuses. But for control and monitoring of multiple sensors separated by long distances, wireless makes sense, experts say.

"With wireless, the cost can go down by a factor of 10 -- not only because of labor costs but because of the wiring," Emerson's Karschnia said. "Wireless is changing the cost paradigm in remote monitoring pretty dramatically."

Senior technical editor Chuck Murray has been writing about technology for 31 years. He joined Design News in 1987, and has covered electronics, automation, fluid power, and autos.

About the Author(s)

You May Also Like