AI Playing Larger Role in Automotive Simulation Systems

Machine learning and deep learning algorithms are helping to construct models for sensor systems and other vehicle functions that help speed design.

Whether it be engines, drivetrains, braking, or even infotainment systems, automotive design continues to gain complexity and increasingly utilizing simulation to examine various design scenarios and trade-offs. In the process, simulation continues to become more data-intensive and time-consuming.

Over the past few years, modeling and simulation software have been incorporating AI and machine learning algorithms to help can cut through some of the complex calculations required to create automotive simulation systems. MathWorks, which supplies programming and simulation tools, has been leveraging its MATLAB computing platform to analyze data, develop algorithms, and create models to help engineers design automotive simulation systems.

“Simulation models are getting more complex, said Seth DeLand of MathWorks, Product Marketing Manager, Data Analytics for MathWorks, in a recent interview with Design News.

According to DeLand, using physics-based model and running data points through it to train an AI model produces a reduced order model that allows for faster data evaluation to help optimize system parameters, which is considered very useful for complex automotive simulation systems.

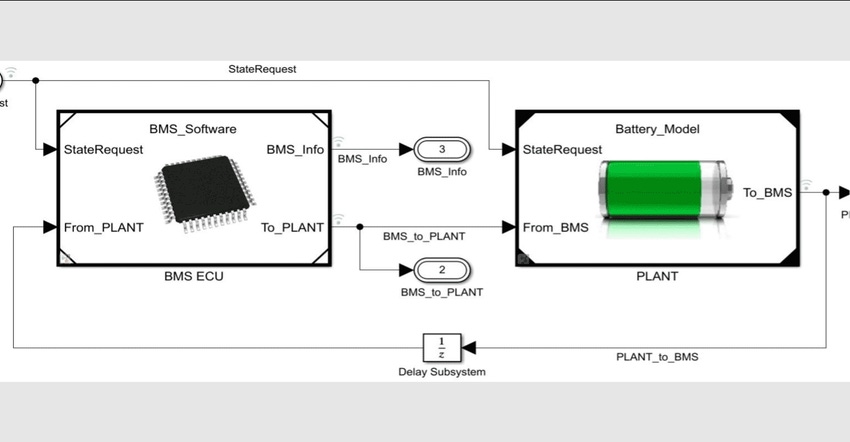

MathWorks teams MATLAB with Simulink, a block diagram environment that is used to design systems with multidomain models and allow simulation before moving to hardware and deploy without writing code. The virtual model allows users to simulate and test systems early and often, and then validate the design with physical models, hardware-in-the-loop testing, and rapid prototyping.

DeLand cited one application, where the simulation and modeling tools use AI algorithms to help estimate the charging state and gauge battery temperature and health, building a virtual model that can be tweaked and optimized before a physical battery prototype is built.

In another application, MathWorks is using its AI- to model vehicle sensors for a customer called Stellantis. Stellantis developed a detailed GT-Suite vehicle coupled with the company’s Simulink too to generate design data needed to model a noxious gas sensor system. The gas sensor system measures the concentration of noxious gases. The video describes how the sensor model is developed.

The machine learning technology on NOx sensor modeling could have a wide range of applications in the automotive industry. “Right now, the model is used to validate sensor readings,” said DeLand. “But in the future, the model could potentially eliminate the need for some of the sensors in the vehicle.”

Spencer Chin is a Senior Editor for Design News covering the electronics beat. He has many years of experience covering developments in components, semiconductors, subsystems, power, and other facets of electronics from both a business/supply-chain and technology perspective. He can be reached at [email protected].

About the Author(s)

You May Also Like