A Tool for Simplified Runner System Analysis and Quicker, Reliable Mold Simulation

July 16, 2015

Design for manufacturing (DFM) in mold production means that mold designers evaluate the manufacturability of their molds in the early stage of mold development by collecting all relevant information and applying it to their designs. They also have to consider many other factors, including flow balance, structural stress, and assembly tolerance, in order to ensure successful molding production. DFM enables mold designers to accomplish design changes and mold optimization in the early stage of the injection molding development process and achieve production goals such as cost reduction, lightweight design, and carbon emission reduction.

In the traditional mold design process, mold engineers would have to decide the total amount of gates and their locations first and then draw up a complete runner system in the initial design stage. Next, they would utilize mold filling simulation software to analyze whether the melt delivery system could achieve flow balance. After completing all of the above tasks, they would arrange the cooling channel layout, ejection system, and other mold base design. Thus, a flow balance analysis is a critical focus in the DFM process.

Taking advantage of higher computing speed and efficiency, an efficient solution for attaining quick simulation results is needed to fulfill the demand for an initial evaluation of the product design in the early stage, with greatly improved accuracy in flow balance analysis. Furthermore, users can run a simulation analysis without importing a complete runner system; they only have to specify the gate locations, and the simulation accuracy can be at the same level as that of a project with a complete runner system.

MORE FROM DESIGN NEWS: Engineers Need to Do More With Less

This solution is based on the same 3D numerical simulation as the analysis project with a complete runner system. It follows the given melt delivery conditions and the law of conservation of energy among the gates when the flow is balanced. In the filling analysis, it also has dynamic adjustments in order to achieve the same analysis accuracy as the one with a complete runner system. Therefore, users can reduce the analysis time spent on a runner system and quickly determine the gate amount and locations. The iterative design time following the addition of the runner system can be further reduced.

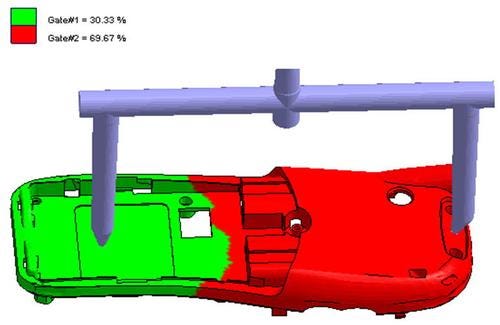

Take a cell phone shell (Figure 1) as an example to compare the results between the traditional analysis process and the enhanced solution.

In the traditional analysis process (Figure 2, left), mold designers would have to create a complete runner system based on the gate locations. In the advanced analysis process (Figure 2, right), users can directly proceed with the simulation analysis without creating a runner system. As shown in the figures below, the simulation accuracy of both gate contribution analyses is almost the same.

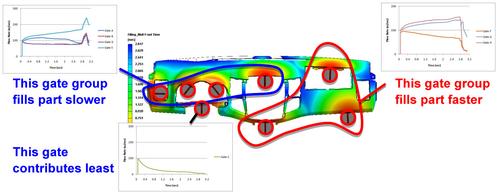

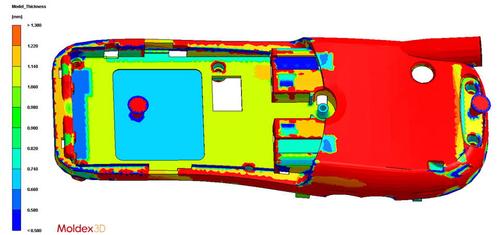

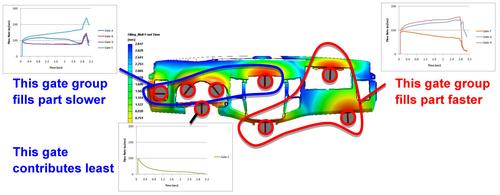

In addition, the advanced solution can improve the gate design efficiency. Take a car interior product as another example (Figure 3). Users can study the history of the flow rate changes in each gate area and identify the gates with poor flow efficiency to further adjust the gate locations and optimize the flow balance.

Advanced simulation analysis enables users to understand the melt flow behavior inside the molds and predict potential molding issues to prevent product defects and deformation. It also facilitates quick validation on design changes and helps users optimize part design and processing parameters more easily. This can further spare designers' time that would normally be spent on building a runner system in the traditional simulation process while still being able to achieve high analysis accuracy.

Especially when mold engineers have to change gate locations, advanced simulation is an ideal aid that can efficiently and rapidly help optimize mold design and significantly reduce simulation time. Moreover, enhanced calculation capability can provide a quicker and more efficient and reliable simulation analysis, allowing designers to speed up the product and development process to maximize their companies' time-to-market competitiveness.

About the Author(s)

You May Also Like