Selecting & Using Background Suppression Photoelectric Sensors

October 14, 2011

Over the past decade, photoelectric sensing has undergone a steady transition in which older, conventional sensors are being replaced by an innovative technology called background suppression (BGS). BGS is a more efficient method of sensing that doesn't rely on how much light is reflected to the sensor's light-sensitive receiver, but rather on where the light is reflected on the receiver.

This endows BGS with certain unique sensing capabilities. The most obvious is its ability to disregard machine panels, belt conveyors, or other materials behind what is to be sensed. It also consistently senses objects regardless of color or reflectivity, so glossy Mylar is detected similarly to brown corrugated cardboard or even black matte painted surfaces. BGS can precisely detect leading edges and small items, such as springs or screws. BGS sensors also simplify sensing by removing the cost and clutter of reflectors and two-housing thru-beam arrangements.

Selecting and setting up the best BGS sensor for an application doesn't have to be difficult if these 10 key points are kept in mind.

1. Infrared has better performance than visible red. When selecting a BGS sensor, an infrared (IR) light source always produces superior sensing performance over a sensor with a visible red light source. Sensors with IR emitters have higher power and lower color sensitivity than their visible red counterparts. This means they can be used at greater sensing distances and can sense different objects more consistently. IR emitters are more efficient and can be driven with higher current pulses compared to visible red versions. The best sensing performance in background suppression is accomplished with fixed-range, short-distance sensors with IR emitters.

In fact, the only advantage to using a visible red emitter is when a visible light spot is needed to align the object to be detected. Alignment can be more desirable than sensing performance in some applications, especially if the item to be sensed is small or is sensed through an aperture.

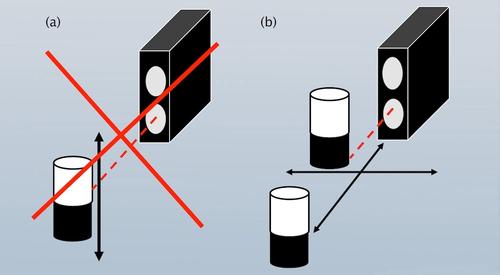

2. A fixed background is better than no background. BGS sensors are designed to compare two signals: light reflected from near objects (such as the material being sensed) and light reflected from far objects (namely, the background).

When a defined signal from a fixed background is present, it minimizes the effect of disturbances in the application, such as dust particles collecting on the sensor's lens in a dirty environment. The reflected signal from the background is easier to see and compare (as opposed to no reflected signal) if there is no background object present.

3. No background is best for detecting small objects. Equally important, a BGS sensor should always be selected so its light spot is smaller than the objects it will detect. This is for good reason: If the sensor's light spot isn't completely covered by the object, then the object reflects some of the sensor's light, but a background material can reflect the remainder of it. And because the sensor determines object presence based on a comparison of reflected light from the near field and far field, it is possible for a small object to not be seen if the sensor's light spot does not cover enough of the object.

BGS sensors are available with laser light spots or fine focal points to detect items that are as small as just a few millimeters.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)