Module Combines Multiple Sensors in a Tiny Package

Combining sensors in a common package reduces size, weight and complexity.

December 1, 2017

A new module from TE Connectivity promises to simplify the development of smart electronic products by incorporating multiple sensors in a package that’s smaller than the head of a match.

Known as the multi-sensor module, the new product can include up to four sensors and a microprocessor, and can transmit data from the sensors through a single set of wires. As a result, it creates a smaller footprint and less mass for applications where minimal size and weight are paramount. At the same time, it reportedly reduces development complexity.

“Design engineers don’t have to figure out a way to mount it on a circuit board, power it up, or develop software to talk to it,” Pete Smith, senior manager for sensor product knowledge and training at TE Connectivity, told Design News. “We do all that for them.”

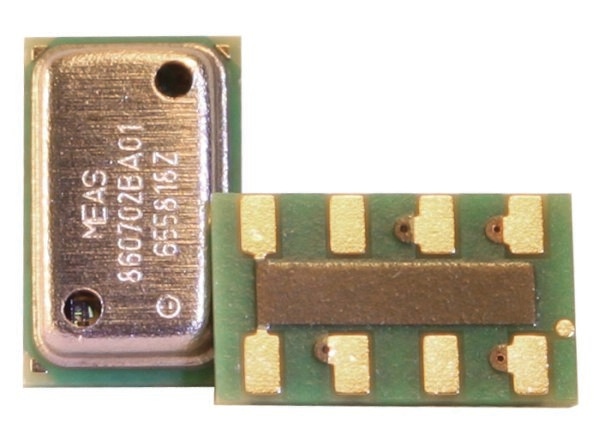

The module can incorporate sensors for measurement of temperature, humidity, pressure, fluid viscosity, fluid density, and dielectric constants, among others. One of the company’s multi-sensor modules includes a temperature sensor, altimeter, and humidity sensor, along with a microcontroller, in a package measuring just 5 mm X 3 mm X 1 mm, Smith said.

|

TE Connectivity’s multi-sensor modules can incorporate multiple sensors in a package measuring 5 mm X 3 mm X 1 mm. (Source: TE Connectivity) |

Early applications of the technology include an automotive windshield module that monitors temperature and humidity, and an automotive engine module that measures barometric pressure, temperature, and humidity in a car’s intake manifold. The windshield application enables a vehicle’s climate system to determine if the glass is about to fog up. The engine application allows the ECU to adjust the fuel injectors to maintain the best air-fuel mixture. The company is also working on medical applications that monitor air quality for respirators, ventilators and incubators.

Additional potential applications include smartphones, tablet PCs, HVAC systems and weather stations.

Smith said that the product was inspired by the demands of customers. “They wanted to combine sensing capabilities into single packages that would provide advantages for developing new products,” he told us. Those advantages include reduced size and weight, as well as simplified wiring. Analog signals from the sensors are digitized and transmitted from a microprocessor or microcontroller through a single set of wires, he said. The technology also provides a logistical advantage because it reduces inventory and eliminates the need for users to deal with multiple suppliers.

TE Connectivity is able to offer multi-sensor packages because it has the advantage of manufacturing many different types of sensors, Smith said. At least 12 different types of the company’s sensors are available for use in the modules, he added.

TE’s multi-sensor strategy comes at a time when many IoT developers are moving electronic intelligence out to the so-called “edge” of their applications. A package that includes multiple sensors and a microcontroller could be a good fit for such applications because it promotes simplicity, Smith said.

“An engineer can take one of these sensor modules, plug it into a board, download the software and have it up and running in a half-hour,” he said. “Whereas, with a boxful of separate sensors, it could take weeks.”

Read More Articles on Sensor Technology

New Ethernet MCU Could Simplify Creation of Sensor Networks

Rethink Adds KPI Collection, Extra Cameras to Sawyer

FDA Approves World's First Pill with an Embedded Sensor

Senior technical editor Chuck Murray has been writing about technology for 33 years. He joined Design News in 1987, and has covered electronics, automation, fluid power, and auto.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)