Guidelines in Using Allegro Angular Sensor ICs

January 21, 2015

Many applications in different industries, such as in industrial automation and automotive sensors and actuators, require monitoring the angle of a rotating shaft either in an on-axis or off-axis arrangement. Magnetic sensor integrated circuits (ICs) are commonly used to perform this task. Here, we discuss on-axis magnetic applications and provide guidelines for using angle sensors based on the Circular Vertical Hall (CVH) technology, which is the core of Allegro angular position sensors referred to in this article.

The design of any angle measurement system is based on the needs of the particular application, such as air gap, accuracy, and temperature range, as well as the properties of the sensor. These parameters as well as magnet selection influence the accuracy of such systems.

A magnetic angle measurement system has two main sources of error:

Sensor IC related errors: Intrinsic nonlinearity; Parametric temperature drift

Magnetic input related errors: Field strength; Field nonlinearity

Each Allegro sensor is tested and calibrated at the factory using a homogenous magnetic field. Intrinsic IC nonlinearity and temperature drift are, therefore, reduced to a minimum before the sensors are shipped to customers. Product data sheets provide temperature drift information.

When using a magnet in a design, the magnetic input will most likely not be homogenous, and the intensity of the field may not be constant over the rotational range. These are errors related to the magnetic input that cause measurement error in the system.

Field nonlinearity and field strength can contribute to the overall error of the system. Both depend on the mechanical position of the magnet relative to the sensing elements. Nonlinearity is described as accuracy error.

Definition of Mechanical Dimensions, X/Y Sensing

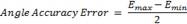

In a Cartesian coordinate system, the sensor is considered a reference, with its package surface parallel to the X/Y plane. The center of the CVH transducer area is defined as the origin (0, 0, 0). The magnet will rotate around the Z axis.

Ideally, the magnet rotation axis will be perpendicular to the X/Y plane, and there will be no offset from the origin (0,0). We refer to any offset from the origin as "misalignment"; in other words, misalignment in Figure 1 is zero.

The distance between the magnet and the sensor along the Z axis is commonly known as air gap. Refer to Figure 2 for details.

Magnet Selection

The choice of magnets is not limited simply to type of material and size; there are also some basic shapes that serve as a good starting point for any system design. One magnet has been chosen as a reference example for the measurements presented in this article.

This magnet example was selected to give basic guidelines. The magnet is designed specifically for angular sensors, and is available from the company Magnetfabrik Bonn GmbH in Germany. Magnet material suppliers can answer specific questions on magnet materials and shapes.

Parameter Definition

Air Gap

Two different air gap definitions can be used when talking about magnetic field sensors: package air gap and crystal air gap.

Package Air Gap

Package air gap is defined as the distance between the top of the sensor housing and the nearest face of the magnet.

Crystal Air Gap

Crystal air gap is defined as distance between the sensing element in the sensor housing and the nearest face of the magnet.

Here, air gap is defined as the crystal air gap (see Figure 2). The sensing elements are 0.36 mm below the top surface of the package.

Angle and Accuracy Error Definition

Angle error is the difference between the actual position of the magnet and the position of the magnet as measured by the sensor device. This measurement is done by reading the sensor output and comparing it with a high-resolution encoder.

The angle error is displayed as a function of misalignment. For that purpose, it is necessary to introduce a single angle error definition for a full rotation. The 'summarized' angle error on one full rotation is defined as angular accuracy error, and it is calculated according to the following formula:

Click here to view Figure 7.

Click here to view Figure 7.

Average Magnetic Field and Air Gap Dependency

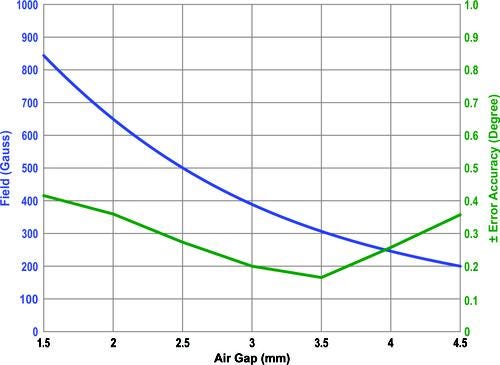

The first step in the angle measurement system design is to choose an appropriate magnet for the application air gap. Usually, the air gap is in a 2- to 4-mm range. Figure 3 shows the magnetic field as a function of air gap for the selected magnet.

By default, many Allegro angle sensors are trimmed to provide optimum performance at 300 Gauss (30 mT). However, Allegro sensors can be specifically trimmed for field strengths beyond 700 Gauss (70 mT). (Additional information regarding specific field strength trimming can be obtained from Allegro representatives.)

Figure 3 shows the angular accuracy error of Allegro's A1334 device trimmed at 300 G (30 mT) when tested with the reference magnet. At each air gap, the magnet was rotated one full turn, and the angular accuracy error was calculated.

The angular accuracy error is influenced by the air gap. The best results are achieved at calibration air gap, that is, the distance where the magnet field strength equals the calibration field strength (300 G).

Tolerance to Misalignment

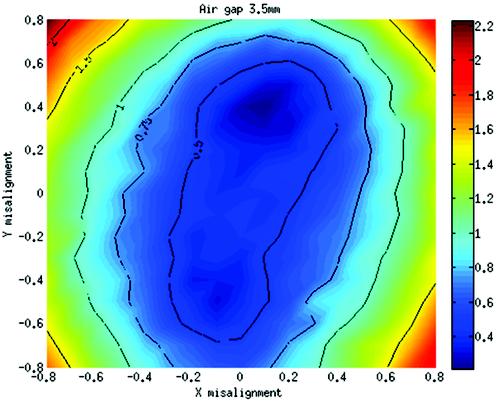

As a result of mechanical placement tolerances, the CVH transducer will not always be placed perfectly in the center of the magnet. To understand how this misalignment can impact the accuracy of the measured angle, the magnet was tested with a different misalignment.

Figure 4 is a plot that shows the results of a multitude of measurements done with the A1334 angle sensor. The air gap was set to the calibration air gap. The magnet was misaligned by plus or minus 0.8 mm from the X/Y origin. At every point in the X/Y plane, the angular accuracy error was calculated for a full turn and displayed in colors.

Summary of Measured Error

The plots provide answers to the following questions:

What accuracy can be expected with a magnet for a given mechanical placement tolerance?

What mechanical tolerance is allowable for this magnet and accuracy?

Repeatability

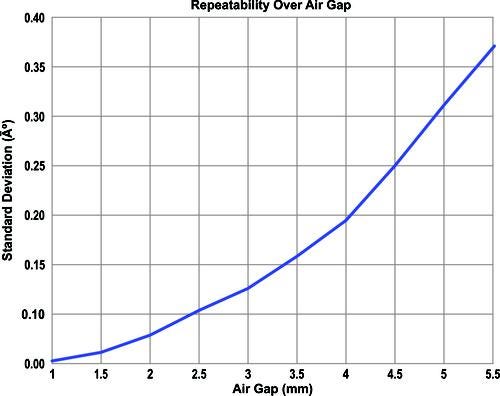

The repeatability of the angle reading depends on the intensity of the magnetic field input. A high input field improves signal-to-noise ratio. Applying this to magnetic sensors means that the repeatability is best at close air gaps. Figure 5 shows the standard deviation of 100 angle readings with A1334. Depending on the possibilities of averaging in the application, this error may be negligible.

Conclusion

Especially in harsh automotive or industrial environments, magnetic angle sensors have proven to be a valuable solution for sensor and actuator applications. Additional features, such as linearization, diagnosis functionality, and redundancy, also support high safety critical applications, such as automotive steering systems.

The design of a magnetic circuit for angle sensors is a complex task, where many influencing parameters need to be considered. Here, we have shown some of the interdependencies that exist between magnet selection, mechanical tolerances, and accuracy requirements for on-axis applications.

Design engineers and professionals, the West Coast's most important design, innovation, and manufacturing event, Pacific Design & Manufacturing, is taking place in Anaheim, Feb. 10-12, 2015. A Design News event, Pacific Design & Manufacturing is your chance to meet qualified suppliers, get hands-on access to the latest technologies, be informed from a world-class conference program, and expand your network. (You might even meet a Design News editor.) Learn more about Pacific Design & Manufacturing here.

About the Author(s)

You May Also Like