The Facts About Using Silicon Carbide Transistors

Understanding the truth behing misconceptions about SiC should give design engineers confidence about using these advanced chips.

June 19, 2023

Ajay Hari, Applications Director, onsemi

Recently, much attention has been focused on Silicon carbide (SiC) and its potential use in power electronics, but this has also generated some misconceptions. Here are some of the most common misconceptions─and the truths─ so engineers can be more confident about using Silicon carbide devices in the future.

Applications

Some of the confusion surrounding Silicon carbide relate to the applications where it can be used. For example, some designers believe that Silicon carbide MOSFETs should be used to replace IGBTs, while gallium nitride (GaN) devices should replace silicon MOSFETs. However, 650 V-rated Silicon carbide MOSFETs offer excellent performance with a competitive RDS(ON)*Qg figure-of-merit and minimal reverse recovery charge. This makes Silicon carbide a good alternative to silicon MOSFETs in hard switching applications like totem pole power factor correction (TPPFC) or a synchronous boost.

Some engineers believe that Silicon carbide is not well suited to higher frequency applications and that GaN should be used instead for fast switching. However, recent technological advances have reduced Silicon carbide die area, further increasing its suitability for high-frequency (>100 kHz) operation. As a result, Silicon carbide devices are now being used successfully in applications like TPPFC at 100 kHz and soft-switching LLC at frequencies between 200 and 300 kHz.

Furthermore, emerging technologies like trench and Cascoded Silicon carbide MOSFETs will enhance its high-frequency performance even more. Finally, other engineers believe that Silicon carbide is a niche technology based on its success in EV traction inverters. However, the requirement for increased power density and efficient operation across almost all sectors means that the benefits of Silicon carbide can also benefit a broad range of less complex designs like EV onboard chargers (OBC), solar photovoltaic (PV) modules and renewables, as well as cloud computing.

Device Selection and Operation

Many designers use a negative turn-off gate voltage to prevent SiC devices from ‘bouncing’ or inadvertently turning back on due to switching transients, but this is not a strict requirement. Many examples of successful SiC designs do not have a negative gate voltage drive. However, as with all designs, good practices should be followed, such a tight layout that minimizes parasitic effects. Further, the gate driver should be able to sink sufficient current to hold the device off firmly. A junction-isolated gate driver may be acceptable in a limited number of applications, such as TPPFC. However, it is worth noting that galvanically isolated gate drivers offer enhanced noise immunity and can better handle switch node dv/dt transients, preventing false tripping.

As SiC MOSFETs switch rapidly and have lower gate charge (Qg) than equivalent silicon devices, a galvanically isolated gate driver makes for a more robust design – even in applications that do not strictly require one. Today, many dedicated SiC drivers offer convenient features like negative gate drive, DESAT, OCP, OTP and other protections. Selecting the right gate driver makes driving a SiC device no more difficult than driving a silicon MOSFET.

Where the Costs Are

There is a misperception that SiC solutions are expensive. Compared to silicon MOSFET, there is a small price premium for a SiC device; however, consider a typical silicon-based 30 kW power solution. Here, 90% of the overall cost is found in the inductors and capacitors (60% and 30%, respectively), with the semiconductor devices representing only 10% of the overall bill of materials (BOM) cost. Suppose the silicon MOSFETs are replaced with SiC switches. In that case, capacitance and inductance size will be reduced by 75%, which delivers a significant cost reduction (as well as size reduction), outweighing the cost increase in the switching components. Furthermore, silicon devices offer lower efficiency than SiC, requiring expensive and bulky heat sink solutions. As a result, the total BOM cost of a SiC solution is lower than a silicon equivalent.

The SiC ecosystem is evolving rapidly as technology enters the mainstream. There is now a wide choice of commercially available SiC devices and associated gate drivers in several packaging styles to suit multiple applications. The knowledge base for SiC is increasing throughout the industry as manufacturers increase their support through applications engineering teams, reference designs, application notes, simulation models and tools. Component availability (not just SiC) has recently been an issue for some sectors.

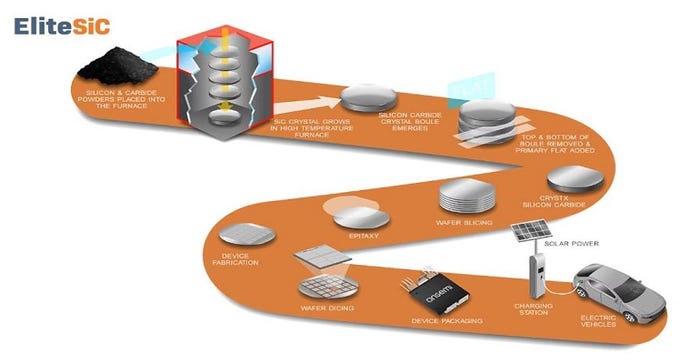

However, following the recent acquisition of GTAT, onsemi’s supply chain is far n capability, including volume boule growth, substrate, epitaxy, device fabrication, best-in-class integrated modules and discrete package solutions. To support the anticipated growth in SiC over the next few years, onsemi plans to increase the capacity of substrate operations fivefold and make substantial investments in expanding the company’s device and module capacity to double it across all sites by 2023. That will be followed by nearly doubling capacity by 2024, with the ability to grow again as required.

Robustness at High Temps and Voltages

The wide bandgap (WBG) of SiC material provides it with better avalanche ruggedness within SiC MOSFETs, as the thermally generated carrier concentration is much smaller than that of silicon devices. While it is true that SiC devices have smaller geometries, so their short circuit withstand time is lower than that of an IGBT, however, using an appropriate SiC gate driver ensures that the fault is detected and device is turned-off with plenty of margin to spare, so they can be used with confidence in applications where robustness is required. The battery voltage on many EVs is moving from 400 V to 800 V or 1,000 V. Within solar photovoltaic (PV) systems, the input voltage is increasing from 600 V to 1500 V.

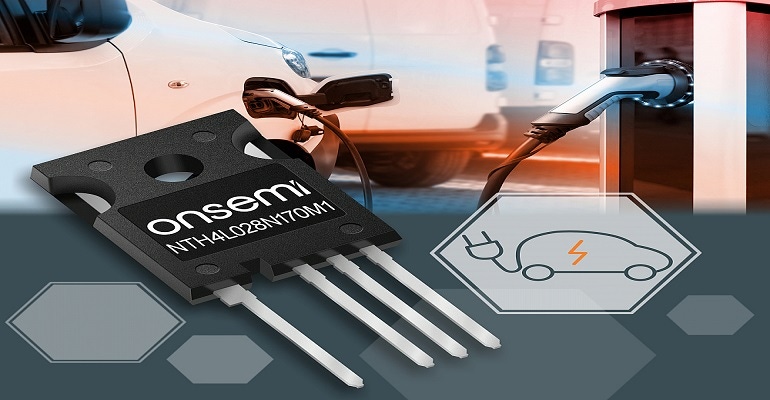

To meet this requirement for devices with higher breakdown voltages, onsemi has developed a range of 1700V M1 planar EliteSiC MOSFET devices optimized for fast switching applications. Alongside these MOSFETs, it has also launched a range of 1700 V SiC Schottky diodes.

The Bottom Line

Having looked at silicon and silicon carbide devices across various metrics, it is clear many widespread misconceptions have no factual basis, and engineers should be confident about selecting and applying this versatile technology in their designs.

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)