Fabrication Simplified for Medical Microrobots

July 28, 2016

Researchers have reduced the geometric requirements for fluid motion in microrobots to simplify the fabrication of machines for tiny medical tasks such as incising tissue, puncturing veins, or targeting drug delivery to specific locations within the body. The research takes engineers a step closer in reducing fabrication challenges to these types of microrobots so they can in the future focus more on functionality.

A team of engineers at Drexel University working under MinJun Kim -- a professor in the Mechanical Engineering and Mechanics Department -- developed a fabrication method comprised of just two conjoined microparticles coated with bits of magnetic debris for the fluid motion of microrobots called "particle-based microswimmers," said U Kei Cheang, one of the researchers on the team and a postdoctoral candidate at Drexel. The name comes from the fact that they consist of particles chained together, he said. These types of robots can be used for in vivo applications such as drug delivery.

What the team did was to use chemical conjugation of beads to fabricate these microswimmers to scale down their geometric requirements, Cheang said. "Essentially, the use of beads allows us to scale ours in two ways: scale the size of the beads, and scale the number of beads. In a way, we can think of the beads as basic building blocks, like Lego pieces," he said.

Specifically, Kim's team combined chemical conjugation with magnetic self-assembly. To bind the four micrometer-wide magnetic beads into pairs, the team prepared two batches separately coated with avidin and biotin proteins, which create one of the strongest naturally found non-covalent bonds, they said. They then exposed these conjoined pairs to one-micrometer iron oxide flakes, which became magnetically adhered to the microsphere surfaces.

This method is far different than many existing methods of fabrication, in which these types of robots are fabricated using specialized chemistry and lithography methods, which involve molds and elastomeric materials, Cheang said. The simplicity of this method lessens the dependency on the specifications of the state-of-the-art fabrication technologies, thus making the microrobots easier to manufacture, he said.

"Conventionally, researchers use expensive equipment or complex methods to fabricate relatively complicated structures, such as helices," he said. "This, we believe, is due to a lack of understanding on how simple microswimmers can be."

READ MORE ABOUT ROBOTICS:

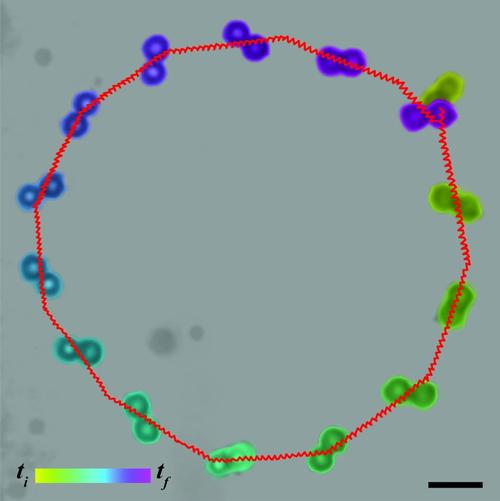

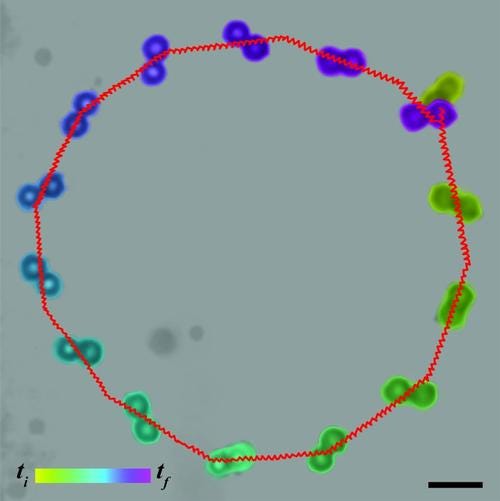

After fabrication, the researchers placed samples of the microswimmers inside a simple chamber fabricated from PDMS, a common silicon-based organic polymer. They then placed the chamber inside an electromagnetic coil system mounted onto a microscope with external controls to manipulate the strength, rotation frequency, and direction of the magnetic field. In this way, researchers could control the swimming motion, speed, and direction of the microswimmers, they said.

Kim, Cheang, and their colleagues published a paper on their work in the journal, Applied Physics Letters. They plan to continue their research toward their long-term goal to develop microrobots and nanorobots for in vivo applications by replacing the debris with nanoparticles for a systematic investigation of particle sizes, Cheang said. "This will give us further insights into how we can practically simplify micro- and nanoswimmers," he said.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 15 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)