What Do Test Engineers Do, and Why Should You Care?

Take a peek into the world of a test engineer – and then tell us about yourself! We want to know what part each of our readers plays in the wonderful umbrella known as design engineering.

February 6, 2016

The Design News community is made up of a diverse cross-section of engineering, with many disciplines represented under the umbrella of design engineering. I design test sets. As a test engineer, I am not always sure exactly what happens in other areas of engineering, although I have a general idea, which may or may not be realistic. The same holds true vice-versa: What are the job functions of a test engineer, you might want to know?

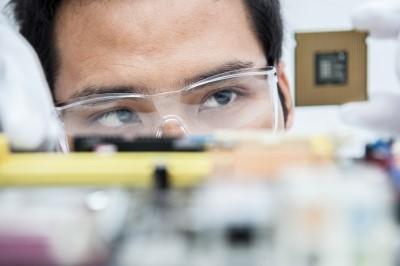

While I have specific experience in some areas of test engineering, in other areas I would be a complete newbie. Test engineering consists of both hardware and software testing and can take place at the chip, device, product, and system levels. Test engineering systems can take measurements, monitor performance, and collect data, but it can also overlap into automation and control. Test engineering can occur during prototyping and qualification and at any stage of the life of a product.

Test engineers may need to design hardware, write software, create PCBs, design fixtures for the device under test (DUT); write user and maintenance manuals; provide a variety of data logging methods; troubleshoot a computer issue; install interface boards; and debug systems for proper communication between products utilized as part of the test system.

At the semiconductor company where I was employed for 12 years, I worked both in product engineering and test engineering. Because the products (Hall-effect devices) that I worked on in product engineering needed a way to be tested as we worked on product development, characterization, and qualification, I simultaneously wore a test engineering hat. I developed test sets that were not meant for production, but were critical in testing our Hall effects during the prototyping and improvement process of our unipolar and bipolar devices, as well as when we developed new parts that needed to pass qualification, such as linear Hall effects, which required a different testing methodology.

[Meet and network with fellow engineers at Pacific Design & Manufacturing, Feb. 9-11, at the Anaheim Convention Center.]

Transferring into the test-engineering department changed my perspective. While the principles of testing remained the same, test sets were built with an eye toward production lines. We were no longer characterizing the device for product development; we were testing the device to get it out the door and into the customer’s hands. This required a paradigm shift in test-set approach, yet was still test engineering.

We built production test sets for many different devices, including Hall-effect devices, photologic sensors and assemblies, LEDs, vertical-cavity surface-emitting lasers, and fiber-optic connectors. Hall effect devices are not easy to test, since they require a precisely measurable magnetic field that can ramp as the DUT stimulus -- add testing across three temps and the need for a mechanized system that would allow the parts to travel from one temp station to the next and be binned according to the test results. That got pretty complicated, but fortunately we had a great team of test engineers and technicians who rose to the challenge.

Then, the QC engineer came, wanting to see if there were any process shifts. Now the test engineer also became adept at implementing statistical process control. I built one test set, where I included a continuous bell curve graph that was seen on the computer screen of the test stand so that the QC engineer was able to glance at it and see the distribution for any test run.

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)