Smart, Predictive Plastics Processing System Boosts Molding Efficiency Up to 30%

SensXPERT technology captures minute material and process deviations to simulate, predict, and analyze material behavior on individual machines.

September 20, 2022

A new, smart process system that combines real-time mold data with machine learning software promises to increase plastics manufacturing efficiency by as much as 30%.

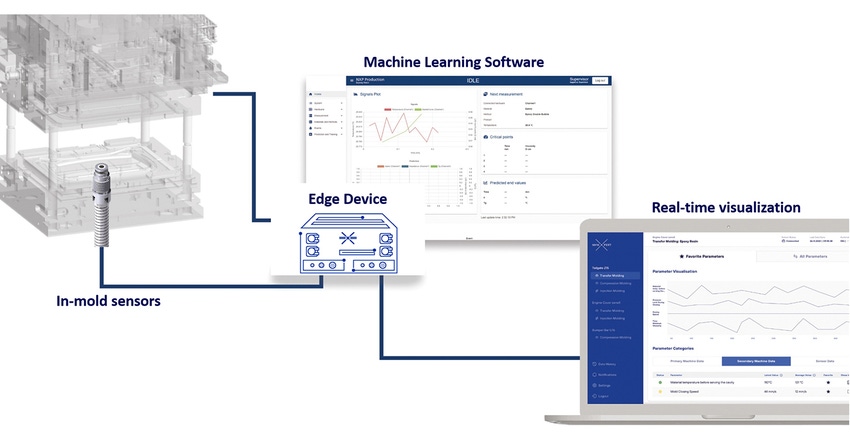

SensXPERT technology from Germany’s Netzsch Process Intelligence analyzes material behavior with in-mold sensors that allow dynamic, adaptive production by reacting to material deviations, the company said. Customers can connect sensXPERT to existing manufacturing and control systems with standard interfaces, or use it as a cloud-based service.

Central to the sensXPERT manufacturing solution is the Edge Device that assesses hardware and software to produce models that capture the most minute deviations in material and process. The resulting algorithms simulate, predict, and analyze material behavior on individual machines. Key parameters like glass transition temperature, pressure, and curing requirements “train” these process models, which are continually refined.

The technology has already demonstrated success in the manufacture of composite automotive wheels and airplane wing components, the company noted.

|

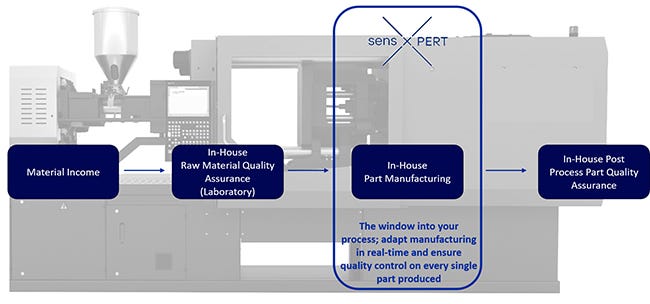

SensXPERT provides a real-time window into plastics processing parameters to ensure quality. |

“Industry 4.0 stakeholders need real-time answers to what is happening in their manufacturing processes,” said Cornelia Beyer, Managing Director and CEO of sensXPERT. “Our unique approach unlocks the potential of fully data-driven productivity, delivering immediate quality and efficiency benefits to our customers in the plastics processing industry.”

SensXPERT technology will work with a broad range of materials and methods — including thermosets, thermoplastics, and elastomers, and injection, compression, and transfer molding or thermoforming, vacuum infusion, and autoclave curing. A web app lets users access the system remotely.

SensXPERT will be on display at the Netzsch Process Intelligence booth C36 in hall 12 of K 2022 in Düsseldorf, Germany, from Oct. 19 to 26.

About the Author(s)

You May Also Like