Engineering Polymers Play Key Role in Drug-Delivery Devices

May 21, 2014

Manufacturers of drug-delivery devices are developing complex new products utilizing high-performance materials to meet specified design criteria. These criteria are physical and mechanical attributes, functionality, reliability, esthetics and ergonomics, compliance with applicable regulatory standards, and, of course, meeting cost objectives. Engineering thermoplastics play a leading role in this growing market, enabling highly functional designs that are lightweight, easy to use, attractive, cost-effective, and meet key compliance regulations.

Semi-crystalline engineering plastics such as acetals, nylons, polybutylene terephthalate (PBT) polyesters, and thermoplastic polyester elastomers (TPC-ET) deliver a wide range of performance benefits. Depending on the resin family and grade chosen, those can include high strength, toughness, low friction, flexibility, high stiffness, chemical resistance, and sterilizability.

Engineering thermoplastics suppliers can help support device manufacturers' material selection by providing timely and relevant product information such as physical properties, chemical resistance, sterilizability data, available regulatory support, and design and processing resources. Engineers designing drug-delivery devices face complex challenges not only from a rigorous regulatory environment, but from a market that demands lighter, easier-to-use, esthetically pleasing, and affordable devices. To help design engineers navigate a sometimes-bewildering selection of materials, this article will outline some key properties, capabilities, advantages, and limitations of the semi-crystalline engineering plastic families most commonly used in highly functional parts for drug-delivery devices.

Drug-delivery devices are becoming increasingly complex. Functional components within these products are integral to ensuring that a device works in a consistent and reliable manner whenever needed, whether on day one or after a two-year shelf life. These demands mean that the proper polymer material selection is critical to commercial success.

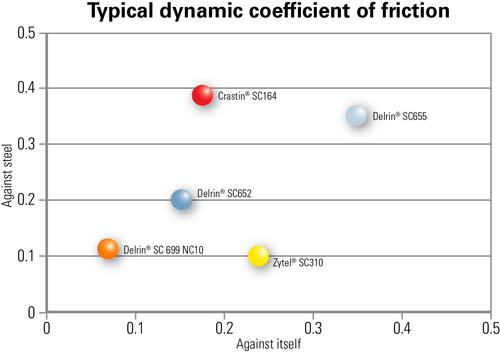

Among today's leading materials options is polyoxymethylene, often referred to as POM, polyacetal, or acetal. It is one of the more versatile, metal-like unreinforced polymers, offering an excellent combination of toughness and stiffness, self-lubrication, and dimensional stability. Gears, springs, and other mechanical components are often made of acetal resins, and more specifically homopolymer acetal, which offer some performance advantages over copolymer acetal. For instance, the high elongation at yield of this material makes it a candidate for snap-fit assemblies. Furthermore, mechanical properties are only modestly affected by moisture absorption. All acetals are susceptible to degradation when exposed to typical gamma or e-beam sterilization conditions. In that case, PBT may be an alternative material.

PBT polyester is less rigid and tough than POM. But, like POM, it has good low-friction properties and combines tensile strength and stiffness with dimensional stability. These properties are minimally affected by moisture absorption at typical ambient conditions. PBT also provides very good color stability when exposed to heat, and excellent surface printing properties.

About the Author(s)

You May Also Like