How Advances in Motor Control Are Lowering Power Consumption

June 17, 2014

Electric motors play a pivotal role in manufacturing, industry, and commercial buildings. Running our machinery, pumps, and climate control, electric motors are truly indispensable.

In manufacturing, electric motors can account for as much as 50% of the total electricity consumption. In commercial buildings, electric motors driving the HVAC system represent as much as 35% of total electricity consumption. These factors, combined with government regulations, have spurred more electric-motor integrators to seek out efficient motors and methods of control for their products.

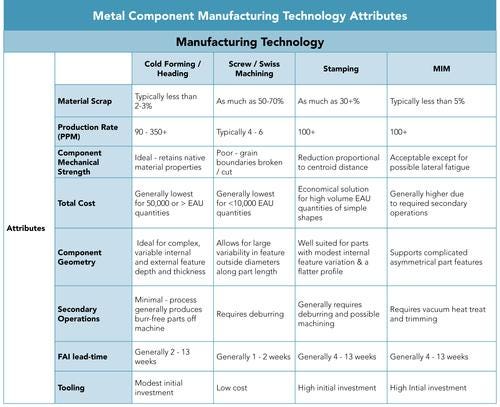

It is estimated that the yearly consumption of electricity by electric motors is 7 trillion kilowatt hours, or roughly 44% of all electricity consumption. For perspective, that is enough to power 150 billion homes. With that much energy being used, the need for efficiency seems natural. However, standard motors can be as little as 55% efficient. Given the average cost per kilowatt-hour in the US of $0.10, an increase to 75% efficiency represents an annual savings of $140 billion (Table 1). Clearly, improvements in motor efficiency can pay big dividends.

Building and residential efficiency -- HVAC

HVAC fans are a common motor application. In fact, they represent 19% of the total electric-motor energy usage worldwide. For the fans in the system, one motor type that can improve efficiency is the Brushless DC (BLDC).

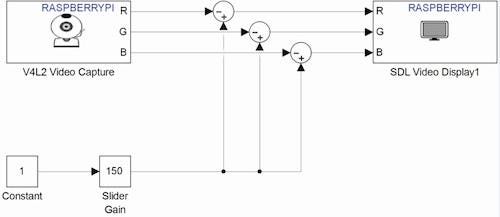

BLDC motors are electronically commutated, meaning that they cannot operate without the aid of electronic drive. These electronics generally consist of a simple 8-bit microcontroller and power electronics.

The microcontroller implements an algorithm that gathers feedback by measuring the back EMF (BEMF), and then drives the power electronics using a pulse width modulator. The incorporation of a simple electronic drive leads to an efficiency improvement of up to 200%.

Pumps and circulators

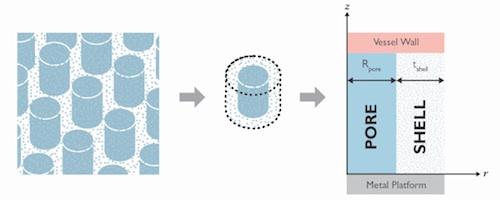

Making up another 19% of worldwide electric-motor electricity usage, pumps are used to move water, sewage, water for district heating, and industrial chemicals. One study of a circulator pump showed that, through the proper application of a speed-controlled pump in existing piping, an electricity savings of 68% is possible. To achieve this level of efficiency, speed control is used in conjunction with a permanent magnet synchronous motor (PMSM). Again, the motor is electronically commutated and cannot run without the aid of an MCU. In this case, the MCU will run a more sophisticated algorithm called sensorless field oriented control (FOC). This algorithm requires the computational horsepower of a 16-bit or 32-bit MCU. It is also helpful to use an MCU that has DSP capabilities, since there are multiple control loops implemented in the firmware.

Compressors

Comprising a whopping 32% of worldwide electric-motor electricity demand, compressors have a big impact on electricity cost and capacity. In the past, the AC Induction motor (ACIM) served this market well, with its fixed speeds and standardized features. These motors can achieve efficiencies as high as 85%, without the need for electronic control. However, the sensorless FOC algorithm can be used to achieve even greater efficiencies.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)