Self-Aware Control Systems

June 19, 2014

The idea of self-aware control systems, though technically within reach, has always seemed to be a futuristic concept. But now with Moore's Law continuing to march forward and control systems able to take on additional computing tasks, we are moving into a phase where it will become more and more of a reality in the form of condition monitoring software and systems.

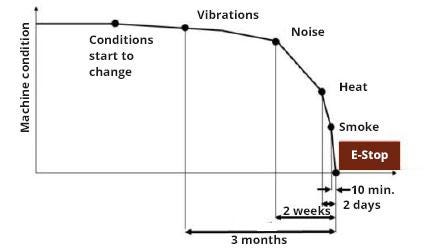

With broad support from automation vendors and an emphasis on software tools that can easily be implemented in machine control projects, the beginnings of self-aware control systems are within reach. However, the current emphasis is on the process of monitoring the condition of machines to predict mechanical wear and failure and determine operating trends that indicate health information about the machine. A main focus is on detecting machine faults early and preventing unexpected failures and costly repairs.

Types of machine condition monitoring

The types of machine condition monitoring serve different roles from route-based monitoring (typically a technician recording data intermittently with a handheld instrument to determine if more advanced analysis is needed) to portable machine diagnostics. Other applications include factory assurance testing and online machine monitoring and protection.

One good example of where the technology is being applied is wind turbine condition monitoring, where there is a significant incentive for effective remote monitoring of these installations. Online machine monitoring is often being used to monitor wind turbines from a central location, so technicians can be deployed to remote wind farms only when maintenance is needed.

Another factor is companies designing larger and more efficient direct-drive turbines, where the need for more advanced factory assurance tests becomes increasingly important. Large test cells will need to be built that can monitor turbine designs for up to weeks at a time to verify these new multi-megawatt designs.

Current shift in thinking

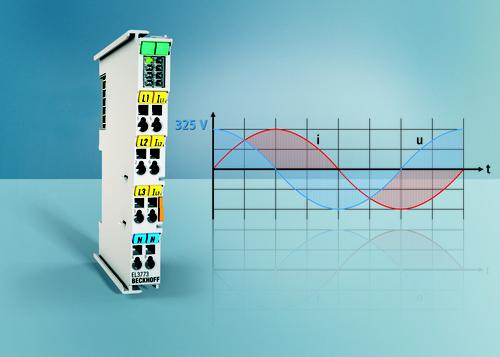

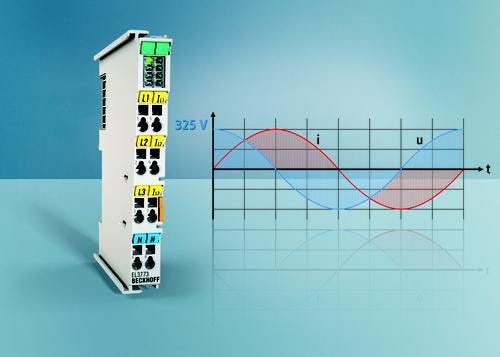

Measurement standards and functionality that have the potential to be the basis of self-aware control systems require a shift in thinking, with measurement technology no longer restricted to a "black box" that is difficult to integrate. Using standard I/O components and sensors, measured data can be captured in a simple, cost-effective, and optimally scalable manner directly at the machine using measuring terminals. The data is then transmitted for processing using high-performance industrial controllers and network communications. The current push with software modules is to combine PLC, measurement technology, and visualization tools on a single platform -- for the purpose of consistently integrating the two worlds of control and measurement technology.

The white paper "The Future of Machines: Self-Aware Control Systems" (registration required) provides an additional resource for machine builders interested in this topic.

Related posts:

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)