Optimization of Total Operating Costs Using Electric Linear Drives

April 7, 2014

Electric linear drives are replacing conventional pneumatic cylinders in more and more applications. The reasons include poor efficiency, high costs for commissioning, reconfiguration, service and maintenance, and the limited control capabilities of pneumatic systems. A recent total cost comparison demonstrates that electric linear drives, at current prices for components and electricity, pay for themselves within a few months even for simple point-to-point motions with two end positions. This also helps to reduce the carbon footprint significantly. In addition, they provide greater flexibility in the design of production processes and production monitoring systems.

Pneumatic drives are characterized by lower acquisition costs, robustness against external influences (e.g., temperature variations and dust), and high resistance to overload. They are also simple to operate and do not require holding current when installed in a vertical orientation. Compressed air is also used for transport and cleaning tasks in many shop floor and industrial environments, so that compressor systems need to be provided in any case. So it's no wonder that pneumatics are used in a wide range of applications and can be found in many factories.

Compressed air, however, is one of the most expensive energy media, because compressors can convert only a small portion of the input energy into useful power. The great majority is dissipated as heat loss. The latest technology can achieve an efficiency of about 30%. Further increases are nearly impossible, as the physical limits have practically been reached. In addition to the already high costs for the motor, compressor, startup and run-on losses, and losses from compressed air handling, in practice additional losses occur due to leaking distribution systems. In reality, therefore, after additional conversion loses in the actuator (without optimization) only about 5% of the input energy is available as useful power. Optimal design of the pipework system and actuators prompt tracking of leaks, and heat recuperation systems can increase the efficiency. The German Environmental Ministry rates the potential energy savings at 20% to 40%, while other experts calculate significantly greater potential savings.

Pneumatics: Two thirds of operating costs are spent on energy

Even if all of these potential savings can be realized, however, compressed air systems still use this input energy very inefficiently, with a maximum achievable overall efficiency of 10%. This can also be seen in the total cost calculation (TCO, Total Cost of Ownership) of a compressor. While about 10% of total costs must be spent on procurement and another 10% or so for maintenance of the system, the energy costs are typically 70% to 80% of the total costs over the service life of the compressor.

It should be no wonder that more and more companies are attempting, in times of rising energy prices and increased environmental awareness (particularly CO2 emissions), to eliminate compressed air from their factories, or at least to reduce it to an absolute minimum.

Today there are, almost without exception, alternatives that do not use compressed air available for compressed air drives. For linear motions in many applications, the very efficient, all-purpose electric linear motor in tubular form is a good substitute. These are available from LinMot in various designs and power classes.

Cost comparison of a pneumatic cylinder and linear motor

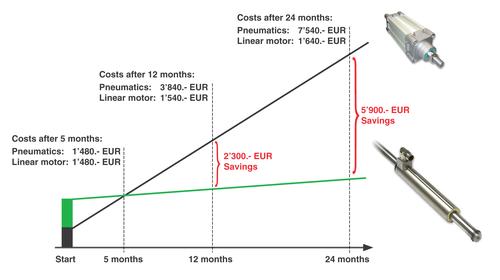

Electric drives are indeed more expensive to buy than simple pneumatic cylinders, but an analysis of the total costs over their service life shows that industrial linear motors can pay for themselves within a few months or even weeks, even in simple point-to-point motions between two positions. An example is Figure 2, with a horizontal point-to-point stroke of 400 mm and 15 kg of mass in motion, operating at 30 cycles per minutes and 50% duty cycle (= 2,000 ms cycle time), makes this clear.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)