Multi-Axis Digital Tension Control

October 4, 2013

In the world of high-performance servo control, one interesting application area that has often been under the radar is multi-axis digital tension control systems, especially as they are implemented in complex web handling applications. What makes this technology unique is a combination of multiple tension control zones, high-speed operation, and the need for systems to apply real-time feedback using sub-millisecond response times.

Digital roll-to-roll web processing is enabling mass production of printed electronic devices by offering high regulated web tension control. One example is Organic Light Emitting Diode (OLED) TVs, which use thin, flexible sheets of material that emit their own light and are produced using a technique similar to inkjet or sheet-fed printing. The key to the technology is that by enabling web applications to be separated into separate tension control zones, tensions can be adjusted in one zone without destabilizing the entire web.

Bosch-Rexroth has published a technical report that provides an overview of this technology, which has its roots in digital printing applications. But unlike sheet-fed printing that uses electronic registration control to achieve product quality, the added complexity is that the substrate in a roll-to-roll press is fed from an infeed reel through the printing section and onto the outfeed reel as a continuous web process. In terms of the servo sophistication required, adjusting tension on each of the sections in real-time, especially since the web itself can be fragile material, is a major challenge.

Added to that is the speed and productivity goals that these applications impose. The report states that digital printers using Rexroth controls can operate at speeds up to 800 ft (240m) per minute. But in roll-to-roll applications, electroluminescent materials or other microcrystalline layers are deposited on substrate at slower speeds, on the order of 10 ft to 100 ft (3m to 30m) per minute.

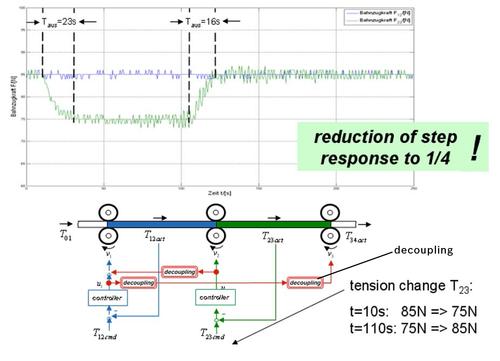

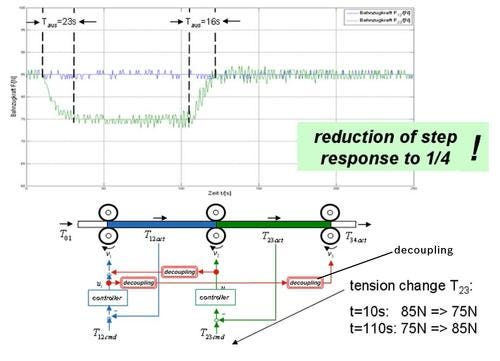

Precision registration accuracy is achieved in these applications by providing superior web tension control and ultra-precise control of transport velocity. One of the reasons why these applications have been so challenging, especially in the past, is the added complexity of dealing with oscillations caused by mechanical misalignments, wide swings of inertial loading during accelerations, and other mechanical slippages. But by decoupling the control of each tension zone and allowing each controller to operate independently, tension can be applied in one zone without affecting other areas of the process.

In the diagram above, the press uses two successive controllers, but the step change signaled by the green section controller doesn't cascade to the upstream process. Along with decoupling to prevent feedback, Rexroth claims that the controller initiates a response to step reduction in tension control in one-fourth the time compared to typical controllers.

A large number of machine designs, especially in printing and packaging applications, use this type of technology. It is an excellent example of how high-performance servo control has been increasingly perfected to deal with extremely difficult dynamic machine conditions. Plus, many of these applications require one or more very large motor-drive combination to deal with large roll sizes, the need for dynamic control performance, and heavy loads.

Related posts:

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)