Moving Toward an Industrial Internet Connectivity Framework

The Industrial Internet Consortium continues its leading role in developing standards, tools, and best practices for implementing IIoT connectivity solutions.

October 18, 2018

A new white paper from the Industrial Internet Consortium is setting the stage for an important publication from this influential standards group—namely, a new Industrial Internet Networking Framework. As a complement to the upcoming framework document, a key goal is to provide advance information which details the requirements and best available technologies for the lower three layers of the Industrial Internet Communication Stack.

Industrial Networking Enabling IIoT Communication

IIoT communication has a number of complicating factors: the convergence of IT and OT technologies, along with technical requirements including network latency, jitter, reliability, and availability. Networks must meet application performance requirements, which can be very different, depending on technical needs of specific systems.

|

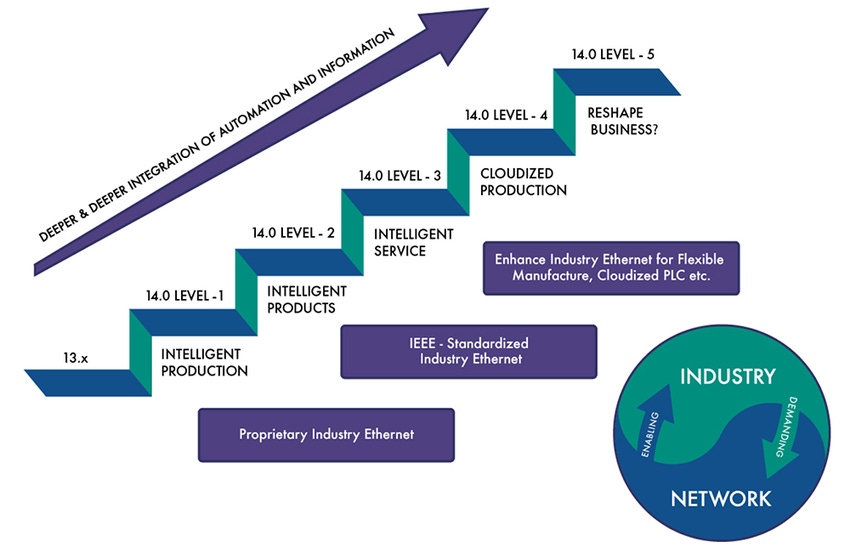

Shown is the Yin-Yang Model of industrial networking and IIoT. (Image source: Industrial Internet Consortium) |

The authors of the white paper include David Zhe Lou (Huawei Technologies), Jan Holler (Ericsson), Clifford Whitehead (Rockwell Automation), Sari Germanos (B&R Automation), Michael Hilgner (TE Connectivity), Wei Qiu (Huawei Technologies), and Manish Sharma (Ligado Networks LLC). They point to the need for tools to assess available technologies and leverage best practices to achieve appropriate IIoT networking solutions.

According to the white paper, “the derived networking requirements lead to the diversity of design considerations, which provides introductory guidance to IIoT solution architects and industrial networking engineers to help them make the right choices.”

Addressing Different IIoT Networking Scenarios

Six different IIoT networking scenarios, or examples, are used to explore how collected data needs to be communicated across industrial networks. One interesting scenario is what they call “elastic virtual industrial control” to address market demands for effectively deploying scalable automation systems.

Today’s industrial processes are typically comprised of distributed subsystems controlled by discrete industrial controllers—often, a programmable logic controller (PLC). Future production systems will need to meet fast-growing market demands for agile and flexible production processes. PLCs offer constrained resources and hardware function is not “elastic.”

One option could be “PLC-as-a-service” at the edge of the network or as part of a cloud solution to help meet the scalable automation requirements of a business. This approach of using an Edge/Cloud-to-Field network could potentially guarantee the required latency and jitter between layers and lossless networks.

Standards and New Technologies

Another important aspect of IIoT connectivity solutions is the network’s role in the Industrial Internet communication stack. Ongoing standards work is addressing needs at the network, link, and physical layers of IIoT networks.

One area where developing an Industrial Internet Networking Framework (IINF) comes into the equation is an ability to provide a conceptual toolbox as well as guidance and recommendations for suitable network infrastructure in various industrial scenarios. A second priority is to create network architectures by applying design considerations onto derived requirements, and a reference model(s) or blueprints for various vertical application areas.

RELATED ARTICLES:

The white paper authors conclude that “because there is no universal or preferred networking technology for IIoT, we introduced the concept of the toolbox and methodology, which will be elaborated in the forthcoming publication of an Industrial Internet Networking Framework. The IINF will include requirements and solutions overviews as well as tools to support the process of deriving requirements from usage scenarios and selecting the appropriate technology.”

The complete white paper on the IIC website is definitely worth a detailed read for automation and control engineers interested in learning more about these future possibilities.

Al Presher is a contributing editor for Design News specializing in automation and control and writing on automation topics, machine control, robotics, fluid power, and power transmission since 2002. Previously, he worked in the electronic motion control field for 18 years, most recently as VP of Marketing for ORMEC Systems Corp (manufacturer of PC-based servo control systems).

|

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)