Mechatronics' Evolution Impacts Use of Modeling and Simulation

October 29, 2010

The term "mechatronics" originally referred to systems combining mechanical, electronic, control, and software systems. Today the term is used to describe a much broader range of systems. The "mecha-" is stretched to encompass domains other than mechanics, and the "-tronics" includes software, control systems, and far more than electronics.

The challenge of integrating different technologies to create a useful, reliable, and exciting device is irresistible to engineers. But it is not a trivial task, especially when you consider that the number and complexity of the integrated systems is climbing. A phone is no longer just a phone -- it can include a camera, keyboard, accelerometer, and much more. Engineers tasked with designing such a system must be prepared with a comprehensive set of requirements and the tenacity to iron out all of the problems that will occur when integrating such diverse systems.

More and more, simulation is being used to detect and eliminate integration issues. Simulation has been used on individual components and subsystems for quite some time, but the real value becomes apparent when you can integrate those individual systems virtually. The tremendous cost savings of finding problems before you commit to hardware are well-known. What's more important, however, is being able to optimize system performance. That's something you can only achieve in simulation when you can combine those different domains with the controllers in a single simulation environment.

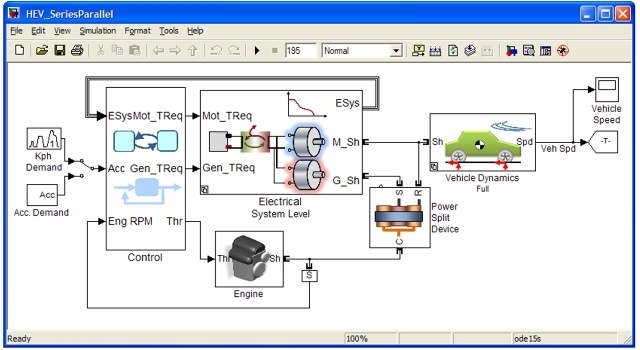

MechatronicsSimulation1 |

Consider a hybrid electric vehicle as an example. Some architectures contain a battery, generator, motor, engine, and a transmission all working together. Though it is possible to simulate each component in isolation, to optimize fuel economy the performance of entire vehicle has to be evaluated. Only then can you truly expect to minimize the amount of fuel used during the drive cycles over which the vehicle will be tested.

Best-in-class Practice

The most successful engineering organizations don't wait until components are selected before they start using simulations. According to the Aberdeen Group, best-in-class organizations are 5.3 times more likely to use simulation to validate system-level behavior. Their design process begins with modeling and simulation, and those virtual tests are used to shape the requirements for the system. Increasing or decreasing the sizes of motors, generators, engines, and other components is more cost effective in simulation than using hardware prototypes, and can take the design team down paths that otherwise may have been left unexplored.

Many automotive suppliers have developed internal libraries to facilitate modeling, simulation, and multidomain optimization. In these instances, a core group of engineers develops libraries of models that span electrical, mechanical and thermal systems to be shared with other teams. Those teams take the components they need, combine them with models of the systems they are designing, and simulate the entire system. By varying the parameter values or using optimization algorithms, those groups can see if the system is meeting design goals. The results of those simulations are fed into the requirements process so that components can be optimally sized.

Expanding Mechatronics' Tent

The breadth of what is considered a mechatronic system is rapidly expanding as new technologies, are developed. By running simulations early in the design process, engineers can try out new technologies and see if they will improve the design. For example, combining piezoelectric devices used in microelectromechanical systems (MEMS) with linear actuators can produce large stroke actuators that also provide precision control (+/- 0.1mm).

For the newest technologies, this can be difficult because there are few (if any) products on the market offering ready-to-use models that include the relevant effects at the right level of fidelity for the application. For engineers to benefit from simulation in these situations, they need to create their own models.

MechatronicsSimulation3 |

Another example is battery technology. It is a hot area of development, as new chemicals, materials and cell geometries are being conceived. In some cases no models exist for the new chemistries that are being used. Many techniques are available for creating these models, but the best ones offer the ability to create reusable components that are linked via interfaces that represent physical connections. Having the option to define the complex voltage/current relationships for a single component, and then being able to use that new component model anywhere in the circuit regardless of what it is connected to, increases the efficiency of the team designing the system.

A common method of defining battery models is to create a battery cell equivalent discharge circuit. This circuit will have a number of components with properties that are dependent upon thermal, state-of-charge, depth-of-charge, and other quantities. Using a physical modeling language to define those implicit relationships per component, and then letting the simulation tool form the equations for the entire network gives engineers the flexibility to rapidly incorporate new battery chemistries into their design process.

Simulating Precision Control

Mechatronic systems rely upon multiple controllers, often interacting with one another. Closed-loop control is often necessary to achieve the precision that these systems require. Hybrid actuators that involve two different technologies as well two different controllers can create a significant challenge for an engineer. For example, pneumatic actuators with a series piezoelectric motors offer both large stroke and fine control. However, the control systems for each system must work together to achieve the precise positioning required by the design. Here again, simulation is key to making sure that the control structure and parameters are optimized for this design.

MechatronicsSimulation2 |

Printing systems are another great example of a mechatronic system in which precision is paramount. In printing machines, cut registers position the printed material beneath roller blades before it is cut into individual pages. For high-quality print magazines, cuts must be accurate to within 0.3 mm. Because the printed material travels through the printing press at speeds of up to 15 meters per second, the control algorithm has just 10 milliseconds to position the cut register. The mechatronic system that positions the paper must be not only extremely precise, but also fast.

An example of a company that uses modeling and simulation to develop high-precision printing systems is manroland AG. Working in the Simulink environment, engineers built a plant model of the press that incorporated performance data gathered from an operating press. They then developed a model of the control system based on a proportional integral derivative (PID) controller. Using modeling and simulation to develop the system was so effective, when tested on the real system the controller immediately worked as designed in the production environment, and it has consistently met the customer's specifications for error rate, accuracy and response time. The ability to perform rapid iterations enabled manroland engineers to optimize quality and functionality while shortening design iterations from weeks to minutes, and reducing overall development time by 50%.

Steve Miller is technical marketing manager for physical modeling tools at MathWorks.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)