Linear Motor Makers Boost Precision, Positional Accuracy

September 22, 2011

New developments in linear motor design are boosting positioning accuracy and enabling the technology to replace pneumatics and rotary motors in some high-precision manufacturing applications, suppliers said this week.

Motor manufacturers at the Design & Manufacturing Midwest show in Chicago said that the new breed of linear motors is taking up residence in semiconductor applications, such as wafer inspection and wire bonding, as well as in other applications, such as pick-and-place machinery, laser cutting, and packaging lines.

"It's a drop-in replacement for pneumatic or hydraulic cylinder applications, but with a lot more efficiency in terms of operating costs," noted Jerame Chamberlain, sales manager for Nippon Pulse America, Inc., a major manufacturer of stepper motors.

At the show, Nippon Pulse rolled out the Green Drive, a new linear motor that reportedly uses 50% less energy than other linear motors producing the same output. Green Drive's linear shaft motor design is different from conventional linear motors in that its magnets are placed in the motor shaft, rather than in a U-shaped channel around the motor's coils. The result, say Nippon Pulse engineers, is significantly higher efficiency.

"You could put this motor up against any linear motor in the world with similar specs, and it will always use less energy," Chamberlain said.

Green Drive could see use in semiconductor manufacturing, not only because of its efficiency, but because of its positioning accuracy, as well. Nippon Pulse engineers said that its positioning resolution is in the range of about 20mum.

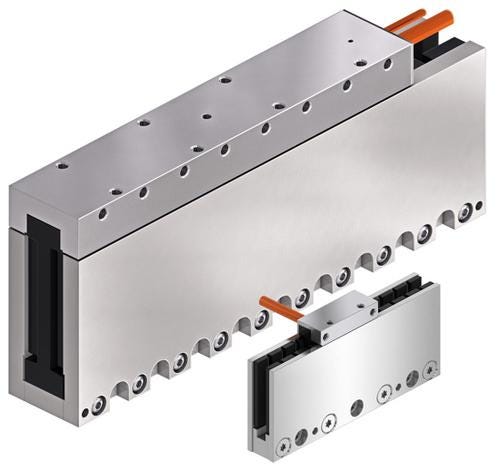

Similarly, Bosch Rexroth AG unveiled its MCL ironless linear motor product line, which achieves positioning accuracies of between 5 and 10mum. In addition to high positioning accuracy, the MCL line is said to offer high linear forces. MCL line's largest motor, which measures about 5" tall, produces a peak force of almost 400lb-f.

"Our target for actuators is about 20% to 30% higher than an equivalent ball screw driven by a rotary motor," noted Joel Galliher, director of mechatronic systems for Rexroth's Linear Motion and Assembly Technologies group.

By employing an ironless design, Rexroth engineers said they have also eliminated the problem of "cogging," which is a ripple force that detracts from the smoothness of a motor's operation. As a result of the high force and greater accuracy, Rexroth said it is targeting pick-and-place and wafer inspection applications, as well as machines that employ precise scanning operations.

Engineers from Nippon Pulse and Rexroth also said that the new breed of linear motors is growing more user-friendly by incorporating components that might otherwise be purchased separately. Rexroth, for example, includes an optional Hall Effect sensor. And Nippon Pulse incorporates self-contained bearings and encoders.

"You take it out of the box and go," said John Odenthal, an engineer with Motion by Odenthal. "You don't have to source out the encoder. You don't have to source out the bearings. All of those headaches go away."

The show, which runs through Thursday, included displays from 15 different linear motor manufacturers and distributors, including IAI America, LinMot, Newport, Techno, Rexroth, and Nippon Pulse, among others.

About the Author(s)

You May Also Like