Industrial Ethernet Creates Value for Process Control

Ethernet/IP support for HART devices is the latest in a series of developments strengthening Industrial Ethernet solutions for process control.

January 11, 2019

An ongoing megatrend in automation and control is the development of Industrial Ethernet technologies targeting the needs of process control applications. Integration of EtherNet/IP with the HART protocol, along with emerging FDI standards, are pieces of a strategic vision for manufacturers looking to maintain cost-effective, sustainable production capacity in the process industries. The potential is that this approach will simplify the exchange of configuration, diagnostic, and production data between field devices and higher-level systems used for supervisory control, data acquisition, and plant asset management.

Integration of HART Devices

A clear example of these developments is ODVA’s recent announcement of enhancements to the EtherNet/IP specification, which outlines how to integrate HART devices into EtherNet/IP system control architectures. This capability is viewed as an important mechanism for process control users to connect with their existing infrastructure while leveraging the benefits of Industrial Ethernet.

|

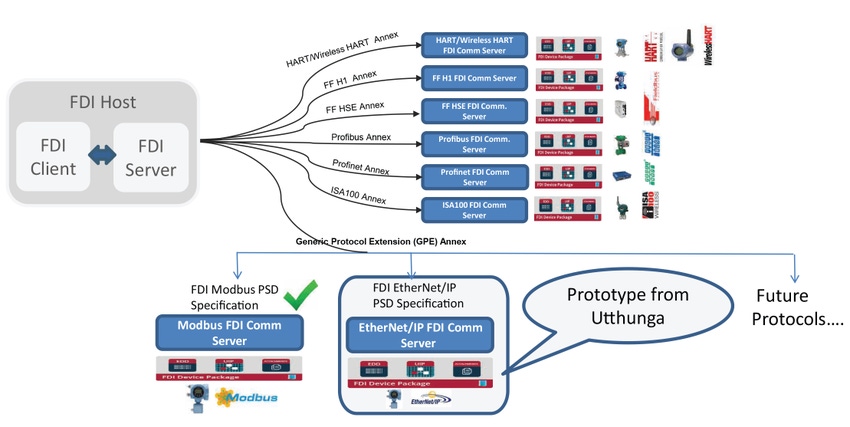

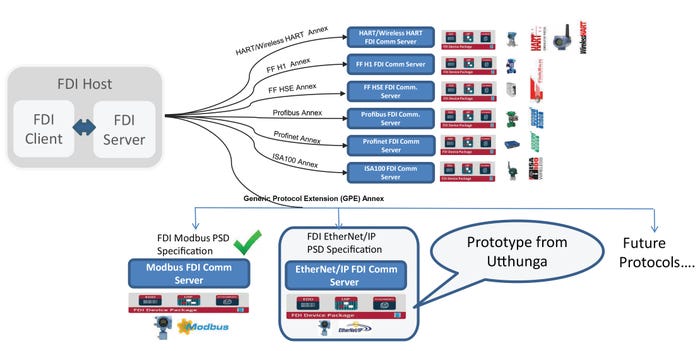

Various industrial communication profiles supported by the FDI specification include HART/Wireless HART, FF H1 and HSE, Profibus, Profinet, and ISA100 using respective FDI communication profiles. The Generic Protocol Extension (GEP) is used to support EtherNet/IP and CIP devices. (Image source: Utthunga Technologies) |

“The integration of conventional HART I/Os is another step in fulfilling ODVA’s vision for the Optimization of Process Integration,” stated Olivier Wolff, chair of the ODVA technical working group for EtherNet/IP in the Process Industries, in a recent press release. “Now that the initial focus to integrate conventional field devices with industrial control systems and asset management systems is complete, the organization will continue to adapt EtherNet/IP to the full spectrum of process industries’ needs, including profiles for field devices to simplify device integration, diagnostics according to NE107, and comprehensive device configuration methods.”

At the recent ODVA technical conference, the working group reported on its efforts on integrating HART with the Common Industrial Protocol (CIP). With these new enhancements to the specifications, a CIP device can communicate with a HART device as if it’s a native CIP device, without requiring changes to the HART device or CIP systems used for industrial control.

Honeywell Process Solutions

At the conference, Brian Reynolds, senior director of engineering for Honeywell Process Solutions, presented the company’s rationale for embracing Industrial Ethernet solutions moving forward. Reynolds said that EtherNet/IP is an important platform for industrial control and, in the future, for overall digitization. The company is already using EtherNet/IP in its Connected Plant solutions to collect meaningful data from devices and to improve overall equipment effectiveness and safety. He said that, by joining ODVA as a principal member, Honeywell is “increasing its contribution to the advancement of EtherNet/IP and related ODVA technology and standards, in order to increase productivity, reliability, safety, security, and digitization in the process and hybrid industries.”

EtherNet/IP + FDI Standards

An ongoing development that is also shaping the development of Industrial Ethernet technologies for use in process applications is the combination of EtherNet/IP protocols, the FDI Device Integration standard, and OPC UA. According to Smitha Rao, co-founder of Utthunga Technologies, the huge installed base of EtherNet/IP devices in both hybrid and discrete industries gives it the potential to become a leading industrial communication protocol for process applications.

Rao added that FDI requirements driven by NAMUR and FDI's flexible architecture provide an ability to add protocols without changing the host implementation, and will facilitate adding more protocols to the FDI standard in the coming years.

The NAMUR position paper, "An Ethernet communication system for the process industry," calls for the EtherNet/IP (IEC 61784-2 CPF2/2) and PROFINET IO CC B protocols (IEC 61784-2 CPF3/5) to become minimum binding requirements for the process industry. It also recommends that FDI device packages required for Field Device Integration (FDI) be available in the devices and capable of being transmitted to central tools.

RELATED ARTICLES:

FieldComm Group has collaborated with the OPC Foundation to create an FDI Information Model, which provides harmonized protocol-agnostic data to the enterprise layer. The EtherNet/IP device-supporting FDI technology can be made available via the FDI Information model to manufacturing execution systems (MES) as well as enterprise applications, such as Enterprise Resource Planning (ERP) and Supply Chain Management (SCM).

Al Presher is a veteran contributing writer for Design News, covering automation and control, motion control, power transmission, robotics, and fluid power.

|

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)