Emergence of an IIoT Ecosystem

April 7, 2015

The Industrial Internet of Things (IIoT) has created a buzz with its focus on how networking will transform manufacturing operations and efficiencies. But the current reality is that while the interest level is extremely high, actual deployments seem to be lagging behind.

One possible explanation is that we're in a process of understanding the complexities of how these systems and field devices such as sensors will operate within the IIoT, along with how to effectively manage these types of projects. Machine-to-machine (M2M) and remote connectivity are really not new concepts, so the real goal may be development of an IIoT ecosystem and technology tools that address integration/security issues and result in a consensus on networking solutions.

Why Not More Deployments?

"Most engineers are bought into the fact that, from the highest level within the IIoT space, there are solutions that provide the ability to measure and monitor more and more data," Mike Fahrion, vice president of IoT Technologies at B+B SmartWorx, told Design News in a recent interview. "Technology is available to make better decisions, reduce downtime, and achieve better use of resources."

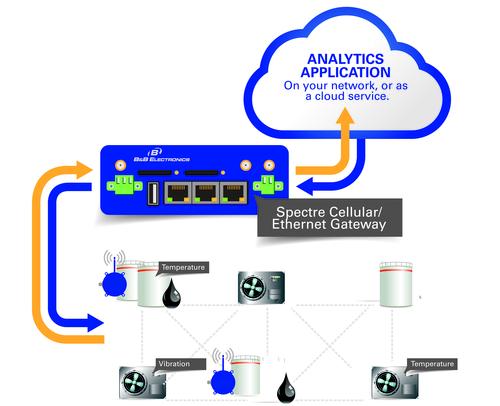

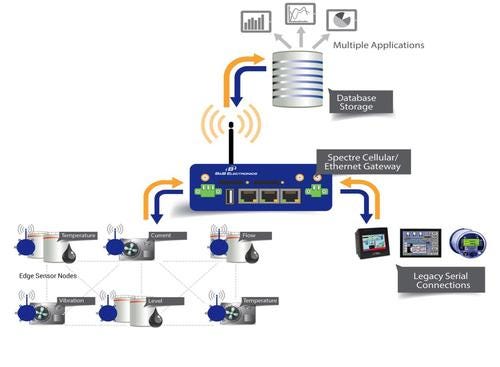

But Fahrion added that the next question often seems to be "why are we not seeing more deployments that fit within the IIoT?" On one level, there are lots of applications and, while a partial answer is semantics, systems are often difficult and complex to implement. An IIoT system can be surprisingly complicated, incorporating sensors to monitor specific values that must be tied into multiple applications and serve multiple clients. Systems can easily require a combination of sensor, networking, and connectivity expertise, with work both at the database level and integration to an ERP system. Suddenly we can be talking about multiple skill sets and departments.

"In the industrial space, the IIoT is expected to include billions of devices, but, when you read the fine print, it's expected that in the industrial world 85% of those connections will involve legacy equipment. That makes complete sense because no one is going to wait until they have all-new machines that use some kind of new communications technology," Fahrion said.

MORE FROM DESIGN NEWS: Battle Scenes from the IoT Standards War

Hardware manufacturers need to ask what can be done to simplify the connectivity stack from the field devices being measured up to the application level. It needs to be as easy as possible to connect devices and physical things at the edge of networks up through the application stack. Fahrion said that, in the past, system communications have primarily been point-to-point; often applications used a serial-to-Ethernet converter. The solution was more about the physical layer without any solutions to make the data easy to integrate into the application.

"Now we are thinking about the data as well and how to take data around the sensor value, for example, and integrate it with other systems in the plant," he added. "It was one thing to digitize a thermocouple and interface it to Ethernet, and there are many ways currently to do that."

Beyond simply digitizing the data, new technology is also focused on packaging it into an understandable descriptive format with the reading for a sensor at a particular geolocation along with calibration and application information, if that is relevant. The packet can include a friendly name for the sensor and the engineering units instead of sending a 16-bit value into a database. The JSON packet might say, for example, that "the temperature in Mike's office at 11:55 a.m. was 72 degrees Fahrenheit."

"In that model, any system can consume the data without any knowledge of the source of that information," Fahrion said. "Important to this process is the ability to take data from the edge of networks and provide not only the physical or networking layer connectivity but also semantic value around that data. The packets are then more descriptive and can be consumed more easily by one or more enterprise-class applications."

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)