Disc Magnet Motors Hit Sweet Spot

June 18, 2013

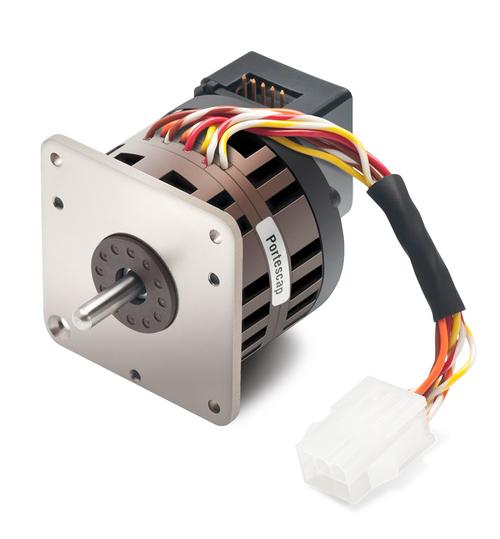

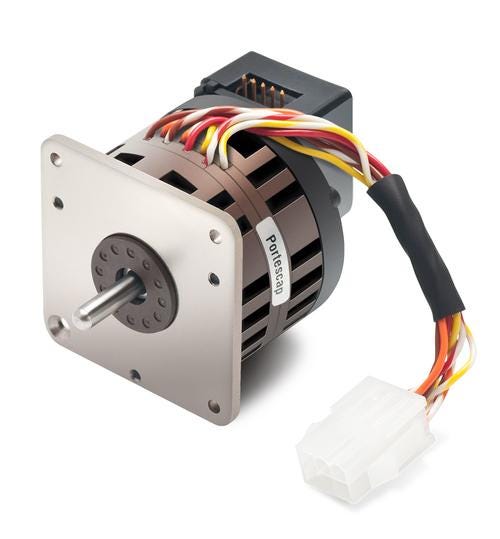

New disc magnet motors fit into the design trend of stepping up to closed loop performance while maintaining the cost advantage of stepper motor technology.

"What we are typically looking at is a middle range as the sweet spot for disc magnet motors," Dave Beckstoffer, project manager for Portescap, told Design News. "Stepper motors typically run at 2,000 RPM or less compared to brushless motors, which can run at much higher speeds. In the few thousand RPM range, disc magnet motor technology is presenting new options for design engineers."

Beckstoffer said there are several different types of stepper motor technology. CAN Stack steppers use sheet metal parts and a very simple construction, but offer very low torque output. The next step up is to hybrid motors, which use machined parts, higher resolution, and pole counts, resulting in higher torque capabilities. But because of the higher pole counts and the construction of the hybrid motor, the big challenge has always been top end speed. The higher pole counts create a higher number of commutations per revolution of the motor. But losses at higher speeds become much more significant and there is more heat generated, versus a brushless motor, which typically uses a lower pole count that enables it to run faster.

"Comparing disc magnet technology to a hybrid stepper, the differentiator is the disc magnet, which doesn't use a cylindrical magnet that you would find in a typical hybrid stepper," Beckstoffer told us. "Our new design uses a high-energy magnet but the inertia of the motor has been reduced significantly by spinning a disc rather than a cylinder."

By using less magnet material, there is less output torque, so comparing a disc magnet and hybrid stepper motor, the disc magnet motor won't produce as much torque, but the design is well-suited for applications with lower inertia and lower torque requirements, but higher speed operation. While the hybrid stepper typically can't operate beyond 1,000 RPM to 2,000 RPM, disc magnet motors can operate effectively up to 5,000 RPM, and smaller motors might reach up to 10,000 RPM.

Beckstoffer said that since stepper motors are typically run open loop, the design standard has always been to add a safety factor. If the application needs one millimeter of torque at 500 RPM, the motor may be sized to two millimeters of torque to insure the motor will move reliably to the commanded position. Closing the loop adds feedback to confirm the position, and the application is able to run at higher speeds without adding the safety factor.

One other advantage of steppers is that they can be driven above their rated current because they are normally not run at a 100 percent duty cycle. Most applications are run at 25 percent or less, which enables the application to utilize 1.5 to 2 times the stepper motor's rated current, while keeping the size of the motor smaller and achieving a higher torque output. By closing the loop, an application can maximize that advantage by boosting the current, especially with the safety factor no longer a consideration.

Beckstoffer said there has been a shift in the motor market where typically in the past steppers were used for open loop and servos for closed loop applications. The trend in the last few years is this middle ground opening up where design engineers are saying they want to have a closed loop system, but the stepper offers the advantages of more torque than a brushless motor because of the higher pole count.

"The sweet spot in applications in the few thousand RPM range opens up where designs can use a closed loop system that is more cost-effective than a brushless solution. The motor has always been available, but the requirement for closing the loop is a design goal that has evolved over the past few years," Beckstoffer said.

Related posts:

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)