Constant Force Springs Versus Spring Reels: Which Is Right?

How do constant force springs compare to the workings and uses of spring reels? Determining which type is best for your specific application depends on knowing the difference between them, as well as understanding the applications for which they are most used.

January 14, 2016

If you are designing a product that requires any sort of smart-motion precision, spring parts that apply constant force or constant resistance are key mechanical design elements to consider.

Two of the most common types of springs -- constant force springs and spring reels -- can be used to complete your design, but determining which type is best for your specific application depends on knowing the difference between them, as well as understanding the applications for which they are most used, respectively. This can help clear away the confusion and give you the satisfaction of knowing you chose wisely.

Constant Force Springs

A constant force spring is produced from a flat steel strip and designed to produce constant force, just as its name indicates. This type of spring is uniform throughout its length and is coiled into a permanent diameter. When extended, the spring will recoil with consistent force. Apart from exerting a uniform force, deflection is only limited by the length of material used for constant force springs.

Constant force springs are commonly used for articulation of medical equipment.

(Source: John Evans' Sons)

Other benefits of using constant force springs include a smooth range of motion, a consistent load in either the extending or retracting direction, and no inertia to overcome. These qualities make constant force springs ideal in the medical field. Various medical devices, such as MRI and dental X-ray equipment, use constant force springs to assist and enhance instrument articulation. The constant force spring is an excellent design component for applications where a constant load is required. Some of their many applications are in counterbalances, door closers, cabinet and furniture components, gym equipment, electric motors, and other long-motion functions.

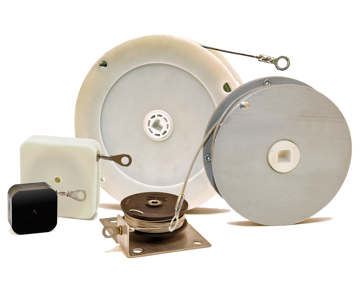

Spring Reels Do the Heavy Lifting

But how do constant force springs compare to the workings and uses of spring reels?

Spring reels can precisely counterbalance loads from less than one pound to more than 50 pounds. Unlike constant force springs, they also provide lift assistance to any assembly that must be raised, reducing the “felt” weight and allowing for maximum travel within the range of motion.

Practically everyone who has lifted a garage door has felt a spring reel in action.

(Source: John Evans' Sons)

Spring reels are commonly used for self-closing and self-opening applications. If you’ve ever intervened between closing elevator doors, you have experienced a spring reel. The spring reels in elevator doors self-close until they hit an obstacle, usually a person’s arm, during which point the doors quickly spring back open.

A spring reel can be used to reduce the energy required to lift a roll-up door on a delivery truck. If you’ve ever rented a moving truck, you have probably experienced a spring reel in action. At first, the door appears heavy to lift, but once the spring reel kicks into action, the door becomes much easier to maneuver and control.

READ RELATED ARTICLES ON DESIGN NEWS:

Spring reels are also used in retail displays as anti-theft devices. If you’ve ever visited an electronics retailer and played with a cellphone at a point-of-purchase display, you’ve discovered the phone was not freestanding but actually had a cord attached to it. As you pulled the device away, the cord extended so you could demo the cellphone, but when you let the phone go, the spring reel snapped the phone back to the display base.

How Spring Manufacturers Can Help

It is always a good idea to consult with a spring manufacturer before choosing springs, especially if you are engineering something that could affect product safety. Even for simpler applications, the knowledge and expertise of the manufacturer can be of great benefit.

A great example of this advantage can be seen in the engineering of a merchandising display. Spring reels can be used as part of a retractable anti-theft mechanism that allows customers to pick up and examine items but not leave the store with them. A spring reel without an enclosed release is probably the best fit for smaller products like cellphones, computer tablets, or cameras.

Along the same line, if you are designing a window, you would not want to use a spring reel, because you don’t want your window to suddenly leap the whole way open at the slightest lift. And while constant force springs would seem to be the ideal solution, even in window applications springs come in many different varieties and may have specific capacities that benefit certain types of windows. Again, consulting the manufacturer or designer of the spring ensures that you are incorporating the most appropriate equipment into your design.

Making the Decision

Many everyday applications utilize the benefits of constant force springs or spring reels, so it is important to recognize which type of spring works better for your situation. If you are still unsure of what type of spring your specific application requires, consult a spring manufacturing professional.

Ed Jones is the marketing manager of John Evans’ Sons, the international leader in design and manufacturing of constant force springs, constant force spring assemblies, and pusher springs (variable force). Custom design, in-house tooling, and precision manufacturing, combined with a wide and varied stock spring selection, allow the company to serve a wide variety of applications from military to medical, high-tech, and aerospace.

Like reading Design News? Then have our content delivered to your inbox every day by registering with DesignNews.com and signing up for Design News Daily plus our other e-newsletters. Register here!

Design engineers and professionals, the West Coast’s most important design, innovation, and manufacturing event, Pacific Design & Manufacturing, is taking place in Anaheim, Feb. 9-11, 2016. A Design News event, Pacific Design & Manufacturing is your chance to meet qualified suppliers, get hands-on access to the latest technologies, be informed from a world-class conference program, and expand your network. (You might even meet a Design News editor.) Learn more about Pacific Design & Manufacturing here.

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)