A Forgotten Practice Can Save US Industry $500B a Year

January 3, 2013

US engineering advancement has been catalyzed over the decades by external threats: the space-race threat from the Soviet Union in the 1960s; the economic threat from Japan's low-cost, high-quality manufacturing in the 1970s; the demographic threat from post-WWII engineering retirements in the 1980s; the global threat as US competitiveness declined in the 1990s; and now the environmental threat driving the need for global energy conservation and sustainability.

In addition, the aging and impending retirement of the baby-boom generation challenges the engineering profession, as these workers take with them a vast amount of knowledge and skill that must be replaced. One critical area, essential in manufacturing and transportation, is tribology, officially defined in 1966 as the science and technology of interacting surfaces in relative motion. Since an undergraduate engineering student receives less than one hour of instruction in tribology in a four-year program, this matter demands urgent attention.

Tribologists, through the development of air-bearing technology in the period between 1960 and 1980, made possible the extremely fast, reliable, precise, and accurate operation of the computer hard-disk-drive read/write head (approximately .05 inch x .04 inch x .01 inch) riding over the disk surface on a cushion of air at a height of 15 nanometers at an average speed of 53 mph. The challenge today for tribologists is to understand the variety of potential modes for wear and surface damage in an endless variety of mechanical systems, e.g., wind turbine components, such as the gearbox, which must last for 20 years without major downtime and costly repairs. Whether the goal is to reduce parasitic friction or enhance friction, the proper combination of geometry, materials, and lubrication must be employed in a design, i.e., a proper tribological approach, to ensure safety, performance, and energy-efficient operation. It has been estimated that the correct application of tribology throughout the US industry could save $500 billion annually.

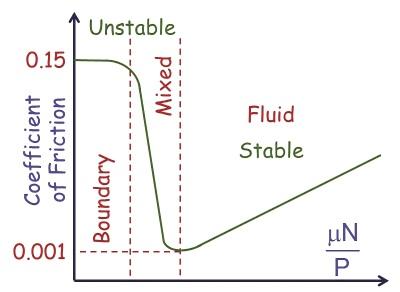

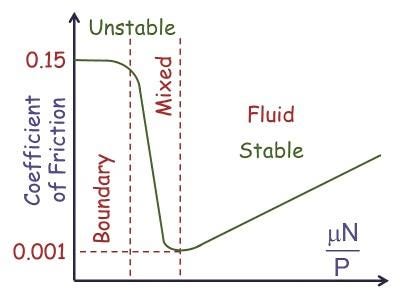

Friction accounts for most of the energy consumed in our society, and friction is inevitably accompanied by wear. The object of lubrication is to reduce friction, wear, and heating of machine parts, which move relative to each other. A lubricant is any substance which, when inserted between moving surfaces, accomplishes these purposes. There are several types of lubrication: hydrodynamic refers to full-fluid-film lubrication, hydrostatic refers to lubricant introduced under pressure to create a full film, elastohydrodynamic refers to lubricant films between elastically deformable surfaces, boundary refers to a fluid film several molecular dimensions thick, and solid refers to solid lubricants used at high temperatures. Unlubricated surfaces have a friction coefficient about 1.0 with heavy wear, for boundary and thin-film lubrication the value is about .01 with slight wear, and for thick-film lubrication the value is about 0.001 with no wear.

The most common of all fluid-film bearings is the journal bearing, where a sleeve of bearing material is wrapped partially or completely around a rotating shaft to support a radial load. Shown is a plot of the coefficient of friction versus Hersey number (μN/P; μ = absolute viscosity in centipoise, N = shaft speed in rpm, and P = average pressure in psi) for a journal bearing under test conditions, and is a good measure of the state of health of the bearing.

There are other areas of science and technology in a similar state. Once this knowledge and skill is lost, getting it back will be near impossible.

Related posts:

About the Author(s)

You May Also Like