Researchers Can Tune Acoustic Metamaterials on Demand

3D-printed acoustic metamaterials are being eyed for new applications in noise cancellation and sound cloaking.

April 28, 2018

Researchers have used 3D printing to develop acoustic metamaterials that can be tuned to different frequencies—something that is a rare quality in these types of structures and opens the door to new applications of them.

The metamaterials, which are capable of blocking sound waves and mechanical vibrations, were developed by a team at USC Viterbi led by Assistant Professor Qiming Wang. They also can be remotely switched between active control and passive states using a magnetic field.

Acoustic metamaterials are materials with negative stiffnesses and/or negative densities designed to control, direct, and manipulate acoustic waves, Wang explained. They are different from other acoustic-mitigating materials—such as a cotton pad—in that they can control acoustic waves within frequencies associated with the local resonances, but not their size scales, he said.

These types of materials are used for noise canceling, sonic cloaking for submarines, acoustic focusing for manipulating small objects, and abnormal acoustic refraction to guide acoustic wave directions. Typically, they have limitations in the flexibility of their applications, however, which Wang said he and his team have solved with their new materials.

|

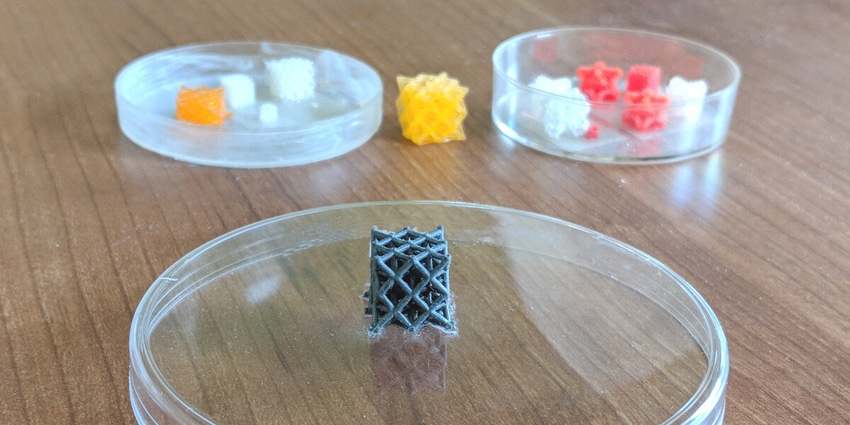

A magnetoactive acoustic metamaterial developed by researchers at USC Viterbi is shown affixed to a petri dish. The material is different from other similar materials in that researchers can use remote magnetic fields to deform its structure, thereby altering the geometry on demand for new applications. (Image source: Ashleen Knutsen, USC Viterbi) |

“Most of the acoustic metamaterials have fixed geometries; therefore, their performance can only be turned on forever and for a certain frequency region,” he explained. “The key innovation of our materials is that we can use remote magnetic fields to deform the structures to alter the geometries on demand.”

This allows the acoustic-manipulating performance of the materials to be turned on and off reversibly and rapidly, Wang said. “The function frequency can also be tuned just by modulating the external magnetic field,” he said.

3D printing plays a key role in enabling this new material function, Wang explained. By 3D printing a deformable material that contains iron particles in a lattice structure, researchers can compress the metamaterials using a magnetic field.

“The 3D-printing technology can enable freeform-design of the structures and can rapidly fabricate the structures,” Wang explained.

READ RELATED ARTICLES HERE:

There are two methods for 3D printing the new materials: directly using magnetic-particle-filled photoelastomers through a micro-projection stereolithography system, or inversely printing by using a water-dissolvable 3D-printed scaffold, he said. In the latter process, the elastomers—filled with magnetic particles—are cured within.

“Both methods can enable the design of 3D architectures of these magnetically active elastomer lattices with high freedom,” Wang said.

Researchers published a paper about their work in the journal Advanced Materials. They are eyeing two types of noise-cancellation and targeted-sound applications for the new metamaterials—switchable acoustic module and switchable acoustic filter, Wang said. The former can be used to block out noise or target music directly for sound optimization.

“When the environment is noisy, you can turn on the magnetic control and the noise can be shielded; when the environment is music, you can turn off the magnetic control and the music can pass to your ears,” Wang said. The latter is for when the environment has both noise and music at the same time, he stated. “You can filter out the noise to leave the music just by tuning the magnetic control.”

Researchers will continue to work on the technology to demonstrate these and other new applications as well as enhance their properties, he added.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time she enjoys surfing, traveling, music, yoga and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like