Metal/Plastic Car Wheel Boosts MPG

February 8, 2013

A wheel made of metal and plastic designed to fit the 2012 MYFord Focus SE has shown an increase of 1.1 MPG highway in third-party tests, compared to the car's standard production wheel. That's comparable to MPG improvements made by some low-roll tires.

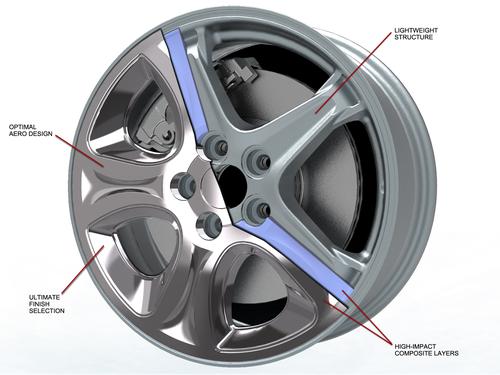

Lacks Wheel Trim Systems' eVOLVE Hybrid Wheel mixes an aluminum structure with a foam filling and a plastic coating. The structure is made of A356-T6 low-pressure cast aluminum alloy, James Ardern, director of business development, told Design News. This is the same aluminum grade, and manufactured by the same low pressure cast process, as the Ford Focus BM5J-1007-DB production wheel. The wheel's outer shell is made of a high-impact polycarbonate/ABS composite blend, which allows a more aerodynamic design, Ardern told us. Between the outer shell and the five-spoke aluminum structure is a high-density, two-part urethane foam, instead of more aluminum.

Lacks tested its eVOLVE Hybrid Wheel, as well as two other wheels, on a North American 2012 MYFord Focus SE on the same day and the same test track. The other two wheels were the eVOLVE wheel's backbone, without its foam filling or coating, and the Ford Focus production wheel. All three are the same dimensions: 17 inch x 7 inch x 50 mm offset. The production wheel weighs 23.7 lb; the backbone alone weighs 17.4 lb, and the complete eVOLVE Hybrid Wheel, including backbone, foam, and composite coating, weighs 19.2 lb.

On-vehicle fuel economy testing was done to EPA standard SAE J2263 by third-party testing facility Roush Emissions Laboratory, which does the same EPA drive cycles for automotive OEMs. The backbone showed some improvement over the production wheel's fuel efficiency. "But it was less of a difference: increases of 0.1 MPG city and 0.5 MPG highway," said Ardern. Using the complete eVOLVE wheel, city improvement was 0.4 MPG, and highway, 1.1 MPG.

Weight reduction alone isn't enough to achieve those results. The other main factor is the eVOLVE wheel's improved aerodynamics. Lacks performed wind tunnel testing of several hybrid wheel designs at third-party aerodynamics testing facility Aerodyn, a NASCAR lab. Lacks then selected the best performing wheel design as the eVOLVE Hybrid Wheel for further testing, Ardern told us.

Compared to the Ford Focus production wheel, in static and rotating aerodynamics testing done to EPA standard SAE J2264 the winning eVOLVE wheel design had an overall vehicle drag coefficient improvement of nine counts. "The reduction of aero drag as well as a reduction in aero horsepower both contribute to the optimized aerodynamic profile, and ultimately to fuel economy performance," said Ardern.

Related posts:

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)