Origami-Inspired Metamaterial Eyed For Robots, Space Station

Harvard University engineers and scientists have designed a new type of metamaterial that can change its size, volume, and shape. Why? To help make possible reconfigurable devices like space structures or robots.

April 13, 2016

Harvard University engineers and scientists have designed a new type of metamaterial that can change its size, volume and shape. Why? To help make possible reconfigurable devices like space structures or robots.

As the team points out in its open access Nature Communications article, reconfigurable devices of many kinds are being designed to serve as emergency shelters, deployable space structures, reversible encapsulation systems, medical tools, and robots.

Robotics engineers are developing multiple technologies to create modular, reconfigurable, and self-reconfigurable robots, as well as self-assembling/reassembling robots, for use as rescue robots and planetary explorers, or even to replace the manufacturing processes of some consumer products. Robotic self-assembly techniques range from the more common macroscale, like MIT's M-Blocks, to Columbia University's molecular-scale nano-robots with moving parts, to the nanoscale, like Harvard's engineered DNA.

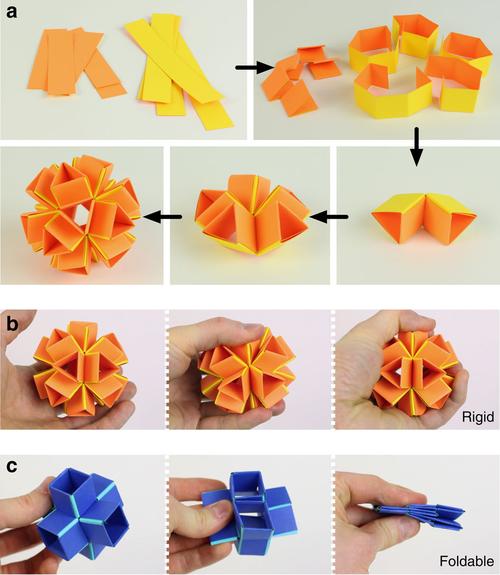

Snapology, a type of modular, unit-based origami, was the team's inspiration for its metamaterial's structure. In this technique, paper ribbons are folded and snapped together to assemble extruded polyhedra, such as the extruded icosahedron shown in (a). Some of the geometries that can be made in this way are almost rigid, including this extruded icosahedron (b). In contrast, other geometries, including this extruded cube (c), have multiple degrees of freedom and can be easily deformed.

(Source: Nature Communications/Harvard University)

To be deployable, as well as to conform to their environment, the structures used for all these applications must have shapes that can be actively controlled. Most of these designs are constructed of materials, and use assembly methods, that are specific to each application. In contrast, the Harvard team has created a mechanical metamaterial that can be used in different reconfigurable devices due to its tunable shape, volume, and degree of stiffness. In the video below, you can see a demonstration of the material and its modular, origami-like structure consisting of extruded cubes with 24 faces and 36 edges made up of rigid faces and hinges connected together.

This transformable metamaterial has three degrees of freedom, meaning it can be actively deformed into multiple, specific, three-dimensional shapes through embedded actuation. Its structure was inspired by snapology, an origami technique. The structure's properties can be actively tuned and controlled by strategically placing pneumatic actuators on the hinges of each unit cell. Cells were fabricated from thin sheets of polyethylene terephthalate (PET). Air pockets were made of polyvinyl chloride (PVC) sheets, embedded within sleeves, and applied to the hinges as actuators for the unit cells. Actuators can be programmed to deform specific hinges, changing a cube's shape and size.

(Source: Harvard University)

The team connected 64 cells to form a cube that can shrink or grow in size, change its shape globally, change its microstructure's orientation, and fold flat. While the structure is changing shape, it's also changing stiffness. This means that, using the same design, it's possible to make a material that's either very pliable or very stiff. Any kind of actuator can be embedded in the material: thermal, dielectric, or even water.

"This research demonstrates a new class of foldable materials that is also completely scalable," said graduate student Johannes T. B. Overvelde, lead author of the article, in a press release. "It works from the nanoscale to the meter-scale and could be used to make anything from surgical stents to portable pop-up domes for disaster relief."

READ MORE ARTICLES ON PROGRAMMABLE METAMATERIALS:

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 28 years, covering manufacturing materials & processes, alternative energy, and robotics. In the past, she's also written about machine vision and all kinds of communications.

About the Author(s)

You May Also Like