HP, Carbon, and Makers of All Stripes Enlist to Combat Shortages of Medical Equipment

Additive manufacturing technology leaders Carbon and HP are helping to produce critical medical parts. Meanwhile, residents at Massachusetts General Hospital have launched a “moonshot” competition to develop mechanical ventilators.

March 24, 2020

As U.S. healthcare providers brace for what could be a flood of patients requiring treatment because of the COVID-19 pandemic, many hospitals have sounded the alarm about looming shortages in critical medical supplies. Some much-needed good news has come from the private sector, as companies put a pause on maximizing shareholder value and pitch in to do their part for the common good. Because of its nimble nature, additive manufacturing, aka 3D printing, is one of the technologies on the front lines. We recently reported on an entrepreneur in Italy who 3D-printed ventilator valves for a hospital that desperately needed them to keep patients alive. Here in the United States, additive manufacturing technology leaders Carbon and HP are helping to produce and deliver critical medical parts. Meanwhile, residents at Massachusetts General Hospital (Mass General) have launched a “moonshot” competition to develop mechanical ventilators.

|

The 3D-printed face shield has been optimized for wearability. Image courtesy HP. |

HP reports that it has delivered more than 1000 3D-printed parts to local hospitals and that its R&D centers in the United States and Spain are collaborating with partners around the world to increase production to meet the most urgent needs. HP is also coordinating with government, health, and industry agencies in numerous countries to ensure a synchronized and effective approach, said the company on its website.

A hands-free door opener, mask adjustment clip, and face shield holder are among the first applications to have been validated and produced, said HP. Hospital-grade face masks and parts for a field ventilator are in the works.

HP and its partners are making the validated design files for many of the parts freely available at this website for download.

|

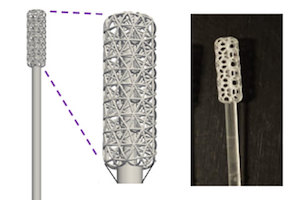

Carbon is working with medical professionals to develop 3D-printed test swabs. Image courtesy Carbon. |

Carbon in a partnership with Verily, part of Google parent company Alphabet, has designed a face shield that can be produced via direct laser sintering and rapidly assembled. San Francisco Bay area hospitals assisted in the design of the shields. Carbon has made the design and production instructions open source to enable additive manufacturers around the world to produce the face shields, as needed. The STL file can be downloaded here.

Carbon has also partnered with healthcare professionals to help increase COVID-19 testing capacity by developing designs for a 3D-printed test swab. Multiple designs are currently undergoing clinical assessment, said the company on its website.

There are multiple examples on the internet of individuals in the 3D-printing community contributing their time and expertise to help local medical professionals, but a far-reaching effort by residents at Mass General really caught my attention. CoVent-19 is described as an open-innovation effort to design a rapidly deployable mechanical ventilator.

The United States has the capacity to ventilate about 170,000 patients, while 960,000 patients are projected to require mechanical ventilators because of COVID-19, according to the CoVent-19 website. This shortage has the potential to put physicians in the untenable position of deciding who gets to live.

The “virtual open moonshot” eight-week competition is hosted on GrabCAD and is sponsored by Stratasys and Ximedica, among others. Engineers, innovators, designers, and makers are invited to participate in the development of rapidly deployable designs. They will be supported by expert medical and technical panels, who will guide their designs. Interested parties are invited to create teams and take part in a two-round challenge with the aim of finalizing device designs by June 2020. For more information, visit the CoVent-19 website.

About the Author(s)

You May Also Like