Thread-Like Pumps Can Be Woven into Smart Fabrics

Fiber pumps make it possible to integrate fluidics into wearable technology, eliminating the need for external pumping technology.

April 13, 2023

While wearable technology has made significant usability gains in the last few years, one thing that's still difficult for engineers to do is to integrate fluidic elements into textiles without tethering them to bulky external pumping technology. That could soon change thanks to new research from scientists at the Swiss Federal Institute of Technology (École Polytechnique Fédérale de Lausanne, or EPFL), who have developed fiber pumps that allow for the integration of high-pressure fluidic circuits directly into textiles, they said.

The pump is basically tubing that generates its own pressure and flow rate and is essentially a "pump in the form of a fiber," said Herbert Shea, head of the Soft Transducers Laboratory (LMTS) in EPFL's School of Engineering, in a news statement.

“Now, we can sew our fiber pumps directly into textiles and clothing, leaving conventional pumps behind," he said.

Those conventional pumps are often large and noisy, making them basically impossible to integrate into a wearable item, the researchers said. The fiber-based pumps now pave the way for innovations including thermoregulatory clothing, soft supportive exoskeletons, fabrics that includes immersive haptics, and other textiles that can include fluidic pumps sewn directly into the fabric of a wearable device, Shea said.

How the Fiber Pumps Work

The design of the fiber pumps is an evolution of fluidics research from Shea's lab that already in 2019 produced the world's first stretchable pump, the researchers said. With the introduction of fiber as the material for the latest invention, scientists now can develop lighter, more powerful pumps that present inherent compatibility with wearable technology, they said.

How the fiber pumps do this is through a principle called charge injection electrohydrodynamics (EHD), which generate a fluid flow in the tubes without requiring any moving parts, the researchers said. This occurs through the use of two helical electrodes embedded in the pump wall, which ionize and accelerate molecules of a special non-conductive liquid, they said. The combination of the ion movement and electrode shape create a flow of fluid, resulting in silent, vibration-free operation that requires only a small power supply and battery for energy, the researchers said.

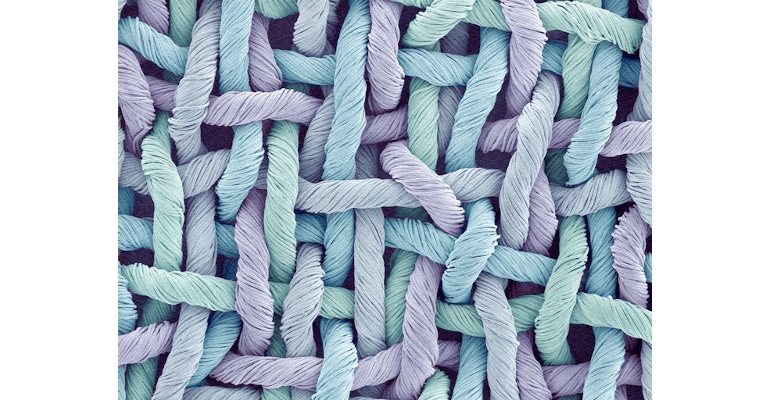

To achieve a successful pump structure, the researchers invented a fabrication technique that involves twisting copper wires and polyurethane threads together around a steel rod, and then fusing them with heat. They then remove the rod, leaving only fibers about 2 millimeters in size that can be integrated into textiles using standard weaving and sewing techniques, they said.

Applications for the Fiber Pump Technology

Researchers published a paper on their work in the journal Science in which they describe some of the applications for the fibers. One of those is to circulate hot and cold fluid through garments that can have several uses, they said. These include helping those working in extreme temperature environments keep a comfortable body temperature; managing inflammation in a therapeutic setting; or helping athletes who want to optimize performance, researchers said.

“These applications require long lengths of tubing anyway, and in our case, the tubing is the pump," explained Michael Smith, an LMTS post-doctoral researcher who worked under Shea's tutelage on the research. "This means we can make very simple and lightweight fluidic circuits that are convenient and comfortable to wear."

Simulating different temperatures through fluidics also could have application in virtual reality in the case of gloves filled with hot or cold liquid that can provide temperature-sensing changes for users during the experience, the researchers said.

The team also described in their study artificial muscles that are created from fabric with fiber pumps embedded within them. These muscles could be used to power soft exoskeletons that can help patients with paralysis or other movement-related injuries move and walk, the researchers said.

Benefits and Future Improvements

The simple design of the pump already presents a number of advantages for its potential uses, though researchers plan to continue their work to make it even better, they said.

Currently, the materials required to fabricate the tubes are inexpensive and readily available; the manufacturing process is one that can easily scale; and the fibers can be washed with conventional detergents.

Moreover, because the amount of pressure generated by the pump is directly linked to its length, the tubes also can be cut to match a particular application, which minimizes the weight of a wearable while optimizing its performance, the researchers said.

Though these already are design advantages, the researchers also aim to improve the performance of their device in areas such as efficiency and lifetime, Smith said. In fact, work has already begun on scaling up the production of the fiber pumps, and the team plans to embed them into more complex wearable devices, a field in which the design has potential to be "a game changer," he said.

About the Author(s)

You May Also Like