Designing EMI O-Rings for Shielding and Sealing

To promote electromagnetic compatibility, consider these material and manufacturing options for EMI O-rings.

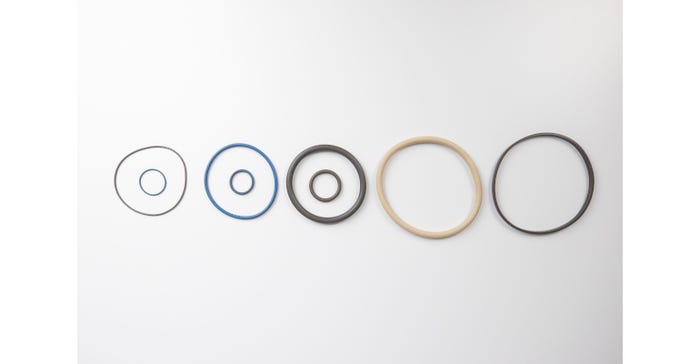

EMI O-rings are donut-shaped gaskets that combine environmental sealing with protection against electromagnetic interference (EMI), a disturbance that limits the effective performance of electronics and electrical equipment. Whether they are propagated through conduction or radiation, the signals that cause EMI limit electromagnetic compatibility (EMC), the ability of different devices to operate without mutual interference. Applications for EMI O-rings include electric vehicles, robotic arms, medical fusion pumps for IVs, 5G telecommunications equipment, and military and aerospace electronics.

EMI shielding like this isn’t the only way to promote EMC and ensure electrical conductivity, but it serves a specific and important function. Electronics designers can also use EMI suppression filters, typically at the inputs and outputs of an electrical system, or at other specific circuit locations for targeted protection. With electronic and electrical enclosures, however, EMI gaskets are needed to fill the gaps between mating surfaces such as lids and panels. These gaskets can be fabricated into various shapes, but EMI O-rings are designed to fit a groove and are crushed in place during installation.

Dimensions and Materials for EMI O-rings

Designers must specify EMI O-ring dimensions such as cross-section and inner diameter, but material selection is also important. Silicones, a family of synthetic elastomers, are normally electrically insulating. With the addition of metal or metal-coated particles, however, silicone becomes electrically conductive. As the base elastomer for EMI O-rings, silicones combine high compressibility with strong environmental resistance, including broad temperature resistance. These EMI gaskets compress to fit the grooves in which they’re placed but can also “bounce back” when the compressive force is removed.

The particles in EMI silicones are made of pure silver, silver coated over another metal, or a metal and a non-metal. Pure silver offers excellent electrical conductivity, but it can be expensive and corrodes easily. Bimetallic particles include nickel-aluminum, silver-aluminum, silver-copper, and silver-nickel. Nickel-graphite and silver-glass particles are made of metal and non-metal materials. Today, nickel-graphite-filled compounds offer shielding effectiveness values of over 100 dB from 100 MHz to 1 GHz. Some of these EMI elastomers also comply with MIL-DTL-83528, a U.S. military detail specification for elastomeric shielding gaskets.

Prototyping and Manufacturing of EMI O-rings

In addition to EMI O-ring dimensions and materials, designers need to consider prototyping and manufacturing methods. To avoid performance problems, project delays, and cost overruns, it’s worth comparing molding vs. bonding. EMI O-rings can be molded as single pieces or bonded from cut lengths of extrusions. Molding supports higher-volume production, but the tooling is more expensive and takes longer to produce. It’s also harder to cost-justify an expensive mold for prototyping if the design could change. Bonding uses simpler and less-expensive tooling, but some bonding methods have drawbacks.

The first way to bond EMI O-rings is with a non-conductive, room-temperature vulcanizing (RTV) silicone adhesive that lacks an EMI filler. This RTV silicone filler might be less expensive, but signals can penetrate the joint and create EMI in the end product. A second approach is to use a non-silicone, non-conductive acrylic glue. This adhesive leaves a “hard spot” in the gasket, however, and acrylic adhesives can’t match the temperature range of the EMI cord stock itself. In EMI O-rings like this, the joint can fail at very high or very low temperatures. That’s an unacceptable risk in medical, military, and many other applications.

The third way to bond EMI O-rings is with a technique known as hot splicing. Unlike the first two methods, which are forms of cold bonding, hot splicing applies heat and pressure to a conductive silicone with a durometer, or hardness, that is similar to the EMI cord itself. This approach reduces the risk of creating a “hard spot” and, because the filler is conductive, helps avoid EMI leakage. Because this technique uses silicone instead of acrylic, the joint also has better temperature resistance for more reliable performance under demanding environmental conditions.

Molding vs. Bonding Example

Consider the example of a designer who orders prototypes of molded EMI O-rings with a 0.93-in. cross-section and a 4.7-in. diameter. The cost is $2500 for a small, one-cavity mold and the lead time is 8 weeks. Fit testing reveals an issue with the enclosure’s dimensions, and the designer needs EMI O-rings with a diameter of 4.9 in. instead. New tooling for another $2500 is ordered, and the lead time is another eight weeks. By the time fit testing is successfully completed, the designer has paid $5000 for tooling alone and waited 16 weeks just to confirm the prototype gasket works.

If the designer had ordered hot-spliced EMI O-rings instead, the savings in terms of time and money would have been significant. Instead of larger and smaller molds, a single hot-splice tool could have been used. The designer could have received samples in both 4.7 and 4.9 in. as well O-rings in an intermediate diameter of 4.8 in. If the designer discovered that the EMI O-ring diameter of 4.7 in. was too small, no additional tooling would have been needed. Production for 4.9-in. diameter O-rings could then have begun using the same hot-splicing tool.

Electromagnetic interference (EMI) is a growing challenge for electronics designers, so it’s important to identify solutions that are dependable and cost-effective and that support the development process from prototyping to production. Molded EMI O-rings that are made of conductive silicones are a good choice for higher-volume manufacturing, or for when a design is fully mature. For lower-volume applications that include prototyping, and especially when there are potential design changes or dimensional issues, hot-spliced EMI O-rings made of conductive silicones demonstrate the value of bonding.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)