Pressure-Sensitive Adhesives Dress Wounds

March 26, 2012

Wound dressings that stick to the skin can be made from pressure-sensitive adhesives that have traditionally been used in food applications. Fabrico, a provider of industrial materials and adhesives, is converting hydrocolloidal adhesives for several medical uses, including short- and long-term wound care, surgical dressings, and ostomy applications.

Medical use is a growing application area for skin-friendly (or "stick-to-skin") material. It includes a range of devices that must stick to patients' skin, such as components for medical equipment. These devices vary in size, shape, weight, cushioning/pressure, absorbency, and duration of contact with the skin. In addition, resistance to heat, moisture, pressure and fluids and compatibility with sterilization are important. All these factors also apply to surgical drapes, dressings for acute and chronic wounds, ostomy appliances, and foot care/cushioning.

Hydrocolloidal self-adhesives can be applied to many substrates on the nonskin side, including polyethylene foam, PVC foam, and polyurethane foam or film. Especially in some newer formulations, they provide alternatives to traditional wound dressings, because they are durable and cause little or no skin trauma. They are impermeable to water vapor when applied but become increasingly permeable and absorb more fluid over time, which helps them cope with continual fluids from wounds. The breathability, conformability, and thickness can be controlled by the dressing's formulation and fabrication methods.

Adhesives commonly used in these applications include epoxies, acrylics, and styrene block co-polymers. The two most commonly used pressure-sensitive adhesive types for stick-to-skin applications are acrylics and synthetic-based rubber. Acrylic adhesives are often used in wound dressings and related applications that must adhere to the skin for long periods of time. Synthetic-based rubber adhesives adhere well to low surface energy substrates, such as low-density polyethylene, but they can be rough on fragile skin.

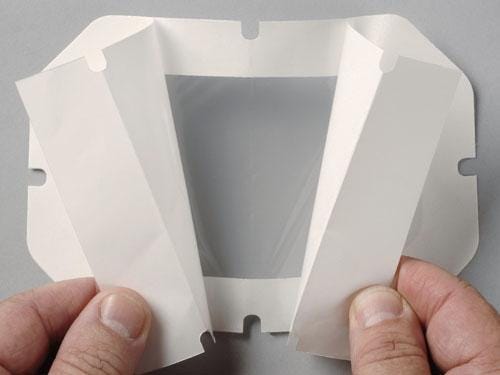

Medical grade adhesives, including hydrocolloids, must comply with International Standard: ISO 10993, Biological Evaluation of Medical Devices Part 1: Evaluation Testing for biocompatibility. Stick-to-skin materials must also be adaptable for material converting operations and designed for high-volume manufacturing. Fabrico is providing hydrocolloidal adhesives in double- or single-coated tapes, as well as in roll form. The company offers precision die-cutting, multilayer laminating, and slitting to tight tolerances. It also provides cleanroom capabilities, including converting and packaging, as well as other medical-grade adhesives and related plastics, foams, and liners.

Related posts:

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)