Adhesive Selection for Extreme Temperature Applications

September 22, 2010

It's nolonger uncommon for aerospace, oil-and-gas, industrial and some electronicsapplications to require materials systems that withstand temperatures of 300 degrees Cor greater. Other applications have to contend with extreme cold, even down tocryogenic temperatures in the neighborhood of 4K.

Pickingthe right adhesive product for extreme temperature applications may seemstraightforward. After all, just about every adhesive supplier publishestemperature resistance values on their data sheets. Relying on that data,engineers will sometimes address temperature issues by simply selecting an adhesiverated for temperatures beyond their application's expected operatingtemperature.

Unfortunately,good design practice is not that simple. Temperature resistance values on datasheets are notoriously inconsistent, in part because suppliers test adhesivesso differently--with some suppliers taking a far more conservative approach toreporting temperature data than others. Toselect the right temperature resistant adhesive for a given application, youwill have to dig a bit deeper than a line or two on a data sheet.

Glass Transition Temperature

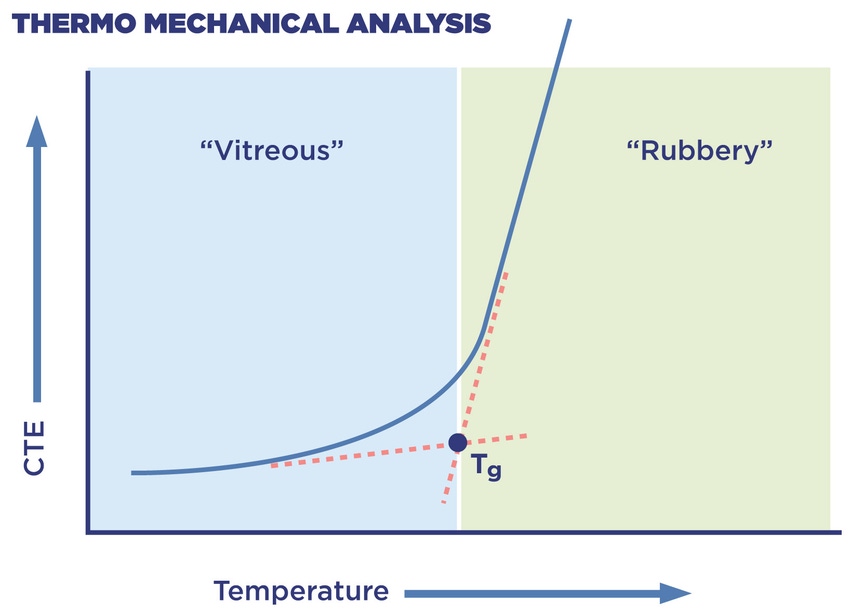

Aspolymeric materials, adhesives share a generalized thermo-mechanical responseto temperature extremes. As the temperature rises past a certain point, theadhesive will begin to soften and lose some tensile strength. The adhesive willalso experience a rise in its coefficient of thermal expansion (CTE). The pointat which very high temperatures start to pose a problem differs with theindividual adhesive and the application requirements. But the adhesive's glasstransition temperature (Tg) provides a window on where that point lies.

Not to beconfused with a melting point, Tg is the temperature at which thermosettingamorphous polymers- including most temperature resistant adhesives-change froma rigid "glassy" state to a more pliable "rubbery" state. This intrinsicthermal property serves as a good indication of an adhesive product's ability tostand up to an application's temperature requirements.

Thermo Mechanical Analysis |

Forexample, it would be unwise to pick a structural adhesive whose Tg is 100 degrees Cless than the application's continuous use temperature. Even in less obviouscases, picking an adhesive with too low a Tg can exacerbate more subtle failuremechanisms such as creep and thermal stresses from CTE mismatch.

With a fewimportant exceptions, adhesives with the best heat resistance tend to have highTg values, making them rigid across their operating temperature range. Epoxiesused to be unmatched in this regard, with some grades offering Tg of 230 degrees C andservice temperatures up to 315 degrees C. Otheroptions, such as a newly developed bismaleimide adhesive from Master Bond (seesidebar), has a Tg of 300 degrees C and predicted service temperatures in excess of340 degrees C.

Theexception to this relationship between heat resistance and a high Tg involvessome silicones and B-stage epoxies. The unique nature of silicones' molecularbackbone and B-stage epoxies' flexible cure state allows these adhesives tocombine relatively low Tg and decent heat resistance-though not as good as thebest epoxies or bismaleimide.

Differential Scanning Calorimetry |

Thosedifferences between the measured Tg and maximum service temperature valueshighlight the fact that the two are not the same thing. Plenty of successfulreal world applications have employed adhesives whose operating temperaturesexceed Tg for short periods of time or by small margins that will not causemechanical properties to degrade enough to matter.

So whileTg is not a shorthand for continuous use temperature, it does serve as anindicator of good design practice in high-temperature applications. Byselecting an adhesive whose Tg is above the expected service temperature, youcan reduce the risk of inadequate mechanical properties or thermal stresses.

Cold Cases

At verycold temperatures, Tg does not provide the same clear window into adhesiveperformance as it does in high temperature applications. As temperatures dipfarther and farther below the Tg, adhesives become increasingly brittle andsubject to low failure stresses. That reasoning would in theory seem to favorflexible adhesives with low Tg values for the coldest applications.

Yet inpractice, the opposite is often true. Epoxy adhesives in particular do notexperience a significant loss of properties even at cryogenic temperatures--meaningthey work best in a rigid state that extends from their Tg into far colderterritory.

How Limited Understanding of Adhesives Can Limit Choices Exaggerating maximum use temperature as a safety measure usually results in the selection of adhesives with higher glass transition temperatures (Tg). That's fine if you actually need all of that added temperature resistance. However, if you don't, you may end up with an adhesive that requires more difficult curing and handling methods. For example, you may find yourself moving from a product with simple room-temperature cure to a product that requires an oven cure. What's more, adhesives with a higher Tg tend to be more rigid materials, which provide less "give" in thermal cycling applications. By opting for more temperature resistance than you actually need, you can unwittingly sacrifice a bit of thermal cycling capabilities. One often neglected factor in determining an appropriate margin of safety is the duration of exposure to elevated temperatures. Many adhesives can withstand 300 degrees C for a few seconds. Increase that exposure to hours, days or months, and the list of suitable adhesive products shrinks to a few epoxies and bismaleimides with high Tg. The message here is not to ignore safety margins, but to determine them realistically and with an eye to the length of exposure. |

As anexample, Master Bond makes one- and two-component epoxy adhesives that providestructural bonds that can handle temperature extremes from cryogenic 4K up to 205 degrees C.Other high temperature epoxies likewise exhibit excellent performance at coldtemperatures above cryogenic levels. This ability to work in environments thatmix extreme heat and cold is particularly important in aerospace applications.

Adhesiveswith a low Tg that function fine in a purely cryogenic environment tend to exhibitlarge CTEs as they heat up-with all the thermal stress problems that large CTEscan imply. High Tg adhesives tend to have smaller, manageable CTEs across theirentire operating temperature range, and may be more suitable for these mixedextreme environments.

Managing Trade-offs

The goodnews about temperature resistant adhesives is that they offer a balance ofproperties that requires little in the way of design trade-offs. These epoxies,silicones and bismaleimides offer all the physical and mechanical propertiesrequired to address a range of structural bonding, encapsulation and sealingapplications.

Temperatureresistant adhesive products are also available with added functional attributes-includinglow-outgassing behavior, thermal conductivity, electrical conductivity, biocompatibilityand more.

Of course,there is no free lunch in the engineering world, and the price of enhancedtemperature resistance comes in the form of more difficult and costly curingand mixing regimens. With epoxies, the grades with the very best temperatureresistance are two-component systems requiring both mixing and an oven cure,possibly with fixturing. One-component systems needing an oven cure are nextbest in the temperature resistance department. Systems requiring roomtemperature cure, while easiest to use, trade off some temperature resistance.

Temperatureresistant products also require careful attention to the manufacturer's curerecommendations. While that advice applies to most adhesive applications, it'sall the more crucial with temperature resistant products because the Tg can belowered by improper curing. Simply put, optimal properties and an optimal curego hand in hand.

RobertMichaels is vice president of technical sales for Master Bond.

For moreinformation, visit: www.masterbond.com

About the Author(s)

You May Also Like