The Future of Manufacturing is Data

Whether it’s predictive maintenance systems or smart PLCs, manufacturers are grabbing data to improve throughput, reduce downtime, and replace retiring knowledge workers.

December 3, 2020

Whether it’s control data or preventive maintenance, IoT or cables, data is the heart of the digital transformation. The critical factor in the success of Industry 4.0 or advanced manufacturing is data. Manufacturers are managing new data streams, data coming from different directions, data getting stored in different places. Ultimately, they’re looking for data to help in reducing downtime, increasing uptime and throughput, and raising quality.

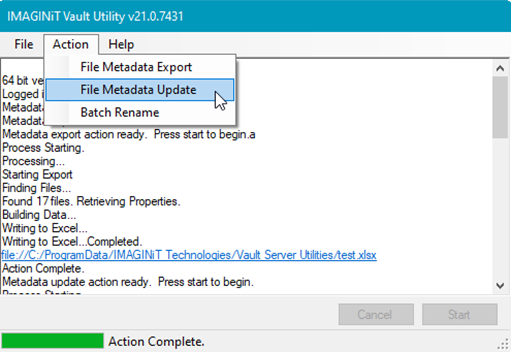

We spoke with Carl Smith, manufacturing solutions manager at IMAGINiT to get some insight into how manufacturers are using data to improve operations. IMAGINiT is a company that helps manufacturing engineers design, develop, and manage projects.

What Data Do You Need?

One big challenge for the manufacturer is figuring out what data is important. “You start at the front. What do you need to know about your business? Do you need to know how many products you’re making? How much do they cost? What’s the lead time? And what data makes that clear?” said Smith. “I need information from human resources. I need to harvest data from the website, from customer feedback. It all starts at the front end. What information do I need, and where do I get that information from?”

The location of that data has changed in recent years. For manufacturers that aren’t part of the biggest 10%, that data was recently on paper. “Data used to be in file cabinets, on timecards. Someone added the timecards up and made a big file. That’s difficult to parse. Are you going to add it up and transpose it?” said Smith. “Now we’re getting used to a system where most of the data is digital. The bridge is moving from a physical file to a PDF. Other data is on websites and surveys and sign-ins. That is the data that lets you know the next service or product you need to provide. A lot of that is data you’re farming.”

Manufacturers Are Swimming in Data

Choosing the data you need and finding where it’s located is one of the major challenges of the digital transformation. “The IoT provides you with billions of bits of data. Manufacturers are struggling with it. Even homeowners with voice-controlled thermostats are struggling with it. That’s all IoT,” said Smith. “How do manufacturers deal with all that data? It won’t be long before a company that manufactures toasters will contact its owner about its use. The manufacturer will let you know your toaster is about to fail.”

The post-sale data collection out in the field is already emerging in the automotive industry. “Modern manufacturers like Tesla are controlling your car after the sale. The IoT is making that real-time. They’ve had this information capability for years. But what do you do with it when it is live-streaming constantly?” said Smith. “On the factory floor, it’s extracted into a real-time resource, a computer, or an iPhone. You can analyze the data for productivity and find out how you can improve operations. That’s cutting-edge stuff and that�’s where the world is going.”

Putting the Data to Work

Using plant data to run operations is no new. The biggest manufacturers have been doing it for years. What’s new is the increase in computer speed and mammoth memory availability. Plus, it has now become affordable for smaller manufacturers. “The big players like Google and P&G have a platform for their data. The small to medium-size manufacturers mostly have an Excel datasheet. But now they’re beginning to custom-develop dashboards,” said Smith. “The advantage of being a small manufacturer is you can adjust quickly to your customer needs. If your manufacturing information is in a datasheet, you may not be able to respond as quickly. With a tool like Autodesk’s Forge, even small manufacturers can extrapolate data into a dashboard. It’s all cloud-based. That’s an emerging market.”

Moving toward a digital factory is helping manufacturers get more use from their assets. “The number-one productivity killer for manufacturers is the weekend. You still have your factory, but it’s not in use. If you can use the information to understand how to do lights-out manufacturing, all of a sudden you can run a second shift with automated information,” said Smith. “It wouldn’t be unusual to turn the lights out and run a second shift. Either that or you’re going to have to staff it and make real-time decisions with brainpower. That’s not cheap and the staff is hard to find.”

Replacing the Knowledge Worker with Data

One big challenge for manufacturers is the retiring Baby Boomer with decades of plant knowledge. That knowledge is walking out of the plant. “The tribal knowledge needs to be captured. That’s your most important asset. It’s been collected for years and years inside the brain,” said Smith. “How do you keep that flowing, capture it, and use it? If you can capture it, years' worth of data will be lost.”

The answer is turning that knowledge into data and handing it over to a data-loving millennial. “That’s called onboarding, and it’s an important factor. When the millennials come on board, you give them access to that tribal data and they will get onboarded quickly,” said Smith. “They have a fresh view. It’s like when you’re working on a jigsaw puzzle and you’re stuck. Then somebody comes up behind you and puts three pieces into place. The millennial brings a fresh set of eyes. It’s all there in the data, and it’s no longer captured in someone's head. Once you get it in the data, all kinds of good things can happen."

Rob Spiegel has covered automation and control for 19 years, 17 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cybersecurity. For 10 years, he was the owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like