Development of a CTE Project: An IoT Electronic Thermometer, Part 2

May 28, 2015

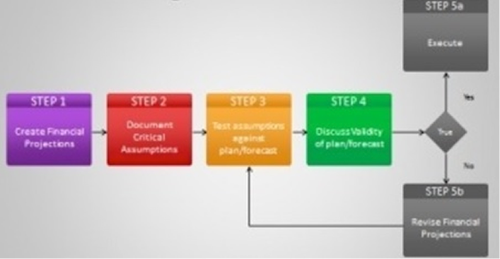

In my previous article, I discussed how I'm developing an Internet of Things curriculum for my CTE (Career Technical Education) high school students in electronics technology by using the Cypress Semiconductor BLE Pioneer Kit with a PSoC board. The emerging technology curriculum's objective is to teach basic design engineering and new product creation methods by way of building an IoT wireless sensor instrument. The new product creation engineering steps I plan to use are summarized, as follows:

Receive customer product requirements

Develop product specifications (hardware/software)

Build proof of concept (PoC) prototype

Test PoC prototype

Demo PoC prototype to customer

Revise PoC prototype for manufacturing production

Product launch

I discussed the importance of receiving customer product requirements and the first developmental gate to designing an IoT device in my previous article. Also, I summarized the process of developing product specifications for hardware and software design elements, illustrating it by using PSoC Creator's hierarchical diagram and the health thermometer's product description document features/functions flowchart.

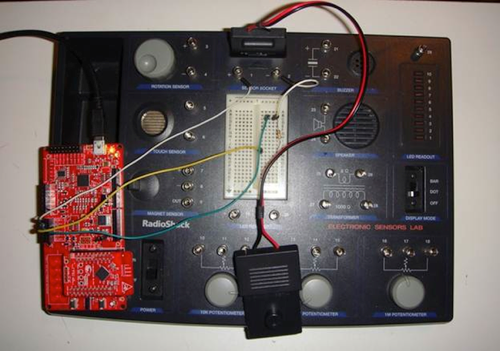

With such product specifications and customer requirements on hand, my students will be able to build PoC prototypes for functional testing. Off-the-shelf electronic kits are great for building the PoC prototypes because of rapid development in wiring circuits using solderless breadboards. Since the IoT product is based on temperature sensing, the Radio Shack Electronic SensorLab was the best choice for building the PSoC BLE electronic circuit interface.

Testing the Health Thermometer PoC Prototype

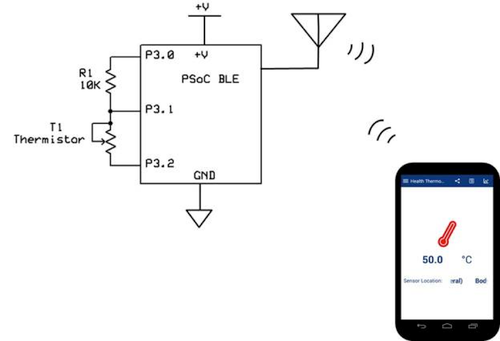

The next phase of the IoT project is to test the PoC prototype of the health thermometer. A small room heater will be used to change the thermistor's resistance so the CySmart app's profile of the health thermometer can display the temperatures on a Bluetooth-enabled mobile device.

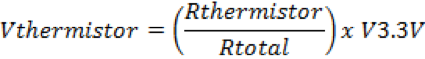

This testing of the PoC prototype provides a technical training discussion on the electrical operation of thermistors and voltage divider circuits. The theory behind the electrical operation of thermistors and voltage dividers can be expressed as a simple equation:

Where:

Vthermistor is the output voltage of the electronic sensor

Rthermistor is the resistance of the thermistor

Rtotal is the summation of the thermistor and 10 kilo-ohm series resistance

V3.3V is the supply voltage (3.3 V) powering the voltage divider circuit.

A DC voltmeter can be attached across the thermistor to monitor the voltage as temperature changes affect its resistance.

The Project's STEM Connection

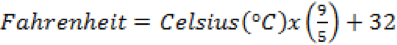

Besides teaching basic electrical circuit theory, the health thermometer is an excellent hands-on tool for STEM projects, as well. The science behind the health thermometer can be explored by way of temperature conversions. I plan on adding a STEM element to the IoT curriculum by having the students convert Celsius to Fahrenheit measurements using the equation:

As Celsius data is being transmitted from the health thermometer's electronic sensor to a smartphone or tablet, the temperature values can be recorded into a lab notebook. Basic math skills in using order of operation can be taught and reinforced with the health thermometer, as well. The final conversion values from the health thermometer can be entered into an Excel spreadsheet.

Two columns will be used for entering Celsius data and the equivalent calculated Fahrenheit values. Graphs can be plotted in Excel to show the relationship of the two temperature scales, thus teaching data visualization and technical interpretation skills, as well.

Prototype Demonstration

With the health thermometer PoC working properly, students will be able to present their products' functional results to the class. Students will discuss the data recorded on Excel spreadsheets and the conversion calculations with classmates. This prototype demonstration activity implements the Alabama State Department of Education's College and Career Readiness Indicator (CCRI) requirement of language arts skills. It's important that all STEM and CTE students demonstrate language arts through verbal communications. The prototype demonstration and data presentation parts of the project and curriculum meet this objective in a hands-on, creative, and technical environment.

Also, the prototype demonstration activity illustrates to STEM and CTE students the importance of communicating engineering design/development progress and technical concerns to the customers of their products.

Revise PoC Prototype for Manufacturability

To illustrate the manufacturing phase of this IoT project, I plan to teach a session on process flow diagrams to my CTE electronics technology students. The process flow diagram provides the methods and techniques for the assembly phase of manufacturing an electronic product. My CTE students will use Excel to design their process flow diagrams for the health thermometer product.Excel has a wealth of drawing tools that can be used in creating a process flow diagram. By showing the basic symbols used in creating a process flow diagram, the educational training behind this lab exercise is to allow students to design the manufacturing build of the health thermometer. Also, this assembly build exercise will illustrate how to revise a PoC prototype for manufacturing production.

The Health Thermometer Product Launch

The final phase of the IoT project is to provide an outreach element to the curriculum. The approach I plan to take is to have a live demonstration and discussion with the school's health science instructor and students. By allowing my students to discuss the operation and engineering that went into developing this healthcare product with the target audience, the education intent is to illustrate the final completion of the project: a product launch into the hands of the customer.

Also, the big picture to this hands-on technology curriculum is to illustrate to my students that the future of IoT and IoE (Internet of Everything) development can be created in today's classroom. As progress of this curriculum continues, I plan to provide updates here in my Design News articles. Stay tuned!

Don Wilcher is a passionate teacher of electronics technology and an electrical engineer with 26 years of industrial experience. He's worked on industrial robotics systems, automotive electronic modules/systems, and embedded wireless controls for small consumer appliances. He's also a book author, writing DIY project books on electronics and robotics technologies. His latest book, Make: Basic Arduino Projects, published by Maker Media, is on the Alabama State Department's approved Career and Technical Education (CTE) reading list. He's currently developing 21st century educational training products and curriculum focusing on Internet of Things (IoT) and Industrial Physical Computing for makers, engineers, technicians, and educators. Besides being an Electrical Engineer, he's a Certified Electronics Technician with ETA International and Alabama State Certified Electronics Instructor.

Atlantic Design & Manufacturing, the largest advanced design and manufacturing trade show serving the Northeastern US, will take place in New York, June 9-11, 2015. It's your chance to meet qualified suppliers, get hands-on with the latest technologies, and expand your network. Learn more here.

About the Author(s)

You May Also Like