Why the Goodman Diagram Is Not So Good

May 30, 2014

One thing many mechanical engineers remember from their classroom days is the Goodman diagram. They may remember it as a tool for designing components for fatigue. If you ever took a class on machine design, you probably did homework problems using the Goodman diagram. If you're a professional engineer, you probably answered questions about it on your licensing exam. You may even use it in your day-to-day work. What you may not know is that it is misnamed, based on a conceptual misunderstanding, and often completely inaccurate.

In fatigue, stress goes back and forth between maximum and minimum values. The value halfway between the maximum stress and the minimum stress is called the mean stress (σm). The distance from the mean stress to the maximum or minimum stress is called the alternating stress (σa).

Fatigue testing is usually done with fully reversed loading, i.e., zero mean stress. On the basis of fatigue testing, an endurance limit is determined. The endurance limit (σe) is defined as the alternating stress at which the material will survive for a given (usually large) number of cycles without failure.

In real-life fatigue situations, the mean stress is often non-zero. For design purposes, it is desirable to be able to relate the actual mean stress and alternating stress in a component to the material's endurance limit. That's where the Goodman diagram comes in.

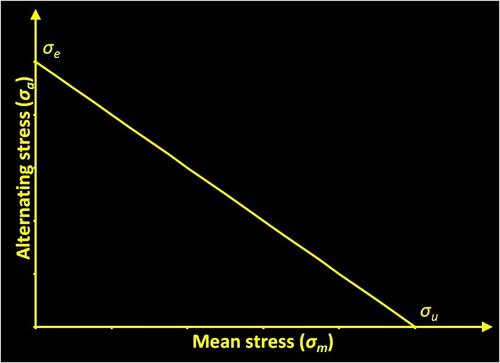

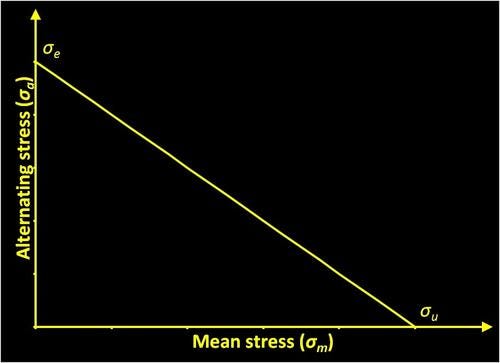

In the version of the Goodman diagram that is most widely taught, the vertical axis represents alternating stress, and the horizontal axis represents mean stress. A straight line is drawn between the material's endurance limit on the vertical axis, and the ultimate tensile strength (σu) on the horizontal axis. To use the diagram, simply plot the actual mean stress and alternating stress as a point on the graph. If the point lies below the line, the component will survive. If the point lies above the line, the component will fail.

Although this is often called the Goodman diagram, in honor of British engineer John Goodman, it is actually different from the diagram that Goodman published in 1899. It is more correctly attributed to another British engineer, B.P. Haigh, who published it in 1917. In Europe, it is called the Haigh diagram.

Regardless of what it's called or who came up with it, it's based on a fundamental error. To understand what the error is, remember what the diagram is supposed to represent: fatigue. Then ask yourself: What is the significance of values along the horizontal axis? Along the horizontal axis, the alternating stress is zero. If there is no alternating stress, how can there be fatigue? The assumption that the ultimate tensile strength is the limit of the fatigue strength as the alternating stress approaches zero may have made sense a century ago, when the nature of fatigue was not well understood. Today, we recognize that fatigue failure and tensile failure are two fundamentally different failure modes. There's no reason to believe that one is a limiting case of the other.

Most importantly, the Goodman diagram can be highly inaccurate. I recently did some fatigue testing on cast aluminum alloy 356-T6, and found that the Goodman diagram consistently over-predicted fatigue lives by a factor of three to four. For example, if the specimen was predicted to survive 1,000,000 cycles based on the equivalent stress determined from the Goodman diagram, it actually failed somewhere between 250,000 and 300,000 cycles.

About the Author(s)

You May Also Like