Reducing Verification Time with Future-Proofed HIL Testing

February 19, 2015

We live in an increasingly software-driven world, and the growth of embedded software in modern vehicles and airplanes challenges manufacturers to continuously enhance product capabilities while ensuring reliability and safety in engine or flight control. Keeping quality a priority when developing and testing embedded software can strain the balance between time to market, test cost, and the ability to meet technical requirements, and, the cost of software development and testing needs to be controlled despite the increase in software complexity.

Organizations that can adapt to this escalating complexity are positioned to thrive in an expanding software environment while those that cannot risk losing market share and industry competitiveness. For example, the Joint Strike Fighter (JSF) military aircraft project has suffered from significant delays and overspending over the years due to software complexity challenges, while automotive and aerospace industry leaders like Tata Motors and Embraer have overcome these challenges by using scalable hardware-in-the-loop (HIL) test platforms.

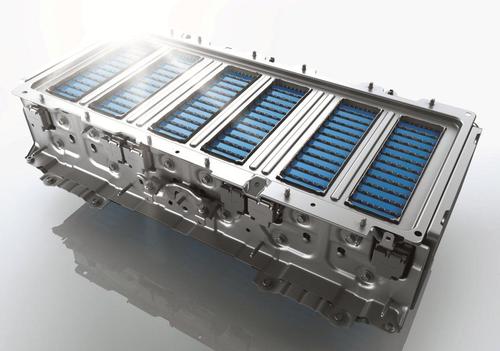

As new vehicle and aircraft designs push innovation, embedded software quality must remain high to ensure the safety of the end users and reliability of the devices. The industry standard practice for embedded software test is HIL testing, an embedded control validation technique where the environment around the controller (device under test or DUT) is simulated on a computer and connected through physical I/O. This enables engineers to perform significant amounts of testing in a lab and reduces time spent on expensive testing in the field. The common response to addressing increases in software complexity is expanding an existing HIL system, yet many labs are not equipped for this scalability and require a disproportionately large investment to accommodate the additional testing.

One problem engineers frequently encounter when deciding to invest in a HIL test lab is the fact that their test systems are not designed to readily increase test throughput, interface options, and system fidelity. New test racks can be purchased, but they come with the overhead costs of assembly, software configuration, and networking with other systems. Test system expansion requirements happen often and relatively quickly within a project lifecycle; additionally, there is the need to integrate multiple unit test systems together to perform system integration testing. Few unit test systems are built with the ability to test the interaction of the original DUT with other controllers in the system. Thousands of channels and hundreds of thousands of variables are interconnected to test large networks of controllers in some of the world's biggest simulation projects, and this type of testing is critical to verify the network capabilities of real-world systems. In the aerospace industry, HIL testing scales all the way to "Iron Bird" testing, where all controllers of the aircraft are interconnected and arranged in realistic relative locations with accurate wiring length. Without considering the transition from unit testing to a system integration lab, extra budget will be spent networking multiple test platforms and reconciling newly introduced bugs found in regression testing.

The cost associated with rigid test systems rises exponentially as products and customer demands continue evolving. The JSF aircraft is one of the largest embedded software projects in the world, and it is currently surpassing $300 billion in development expenditures. With one code change potentially affecting hundreds or thousands of the nearly 25 million lines of code, each software fix could create dozens of additional problems. As a result, it is estimated that some of the current defects related to the aircraft's machine gun will take upwards of four years to successfully patch. Due to the difficulty in modifying such a large code base, it's clear that software testing is a main cause of the project's delays.

On the other hand, in India, Tata Motors needed to address all of these challenges when its verification system unexpectedly grew during development. As the country's largest automobile manufacturer and a leader in commercial vehicles, Tata sought to verify multiple controllers of a hybrid bus within a single test system. The company aimed to build a universal test setup flexible enough to scale to any of their vehicle controller's needs with minimal reconfiguration, while also supporting integration testing of multiple controllers. Initially, Tata Motors based its requirements on four major controller components and built a rigid HIL test system that met those exact needs, but as the designs evolved over a few months, their universal test system requirements for DUT integration increased from four components to six. This change required the company to migrate from the tailor-made system that could not grow to a flexible solution from National Instruments (NI) that provided the scalability they needed in less than two months.

Now imagine this sort of challenge on an even larger project. Brazilian aerospace company Embraer developed its Legacy 500 executive jet aircraft with 50 embedded controllers covering flight control and entertainment as the first full fly-by-wire aircraft in its class. Their previous integration project took three-and-a-half years and they aimed to scale their HIL testing process to verify an increased software load and launch the Legacy in a shorter amount of time. However, the aircraft's 90,000 parameters and signals presented a significant challenge as Embraer sought to build a system that could scale to that size. Through a reflective memory network of 21 real-time computers, Embraer's test system was able to share 70,000 parameters and simulate their entire airplane functionality in real time. Their engineers were able to construct this system in just 30 months, saving nearly 30% of their verification time.

Related articles on DesignNews.com

By identifying an approach that had been designed with growth and scalability in mind, Tata Motors and Embraer were each able to "future-proof" their systems to a great extent. In these specific use cases, these companies reduced their testing schedules and expenditures while building a platform that scaled with their needs. Like many other NI customers, Tata Motors and Embraer overcame the challenge of increasing software complexity while adapting to changing requirements by leveraging the power of an HIL platform.

Kyle Perkuhn is product marketing engineer, VeriStand at National Instruments.

About the Author(s)

You May Also Like