Microdisplays Promise to Improve Viewing in AR Apps

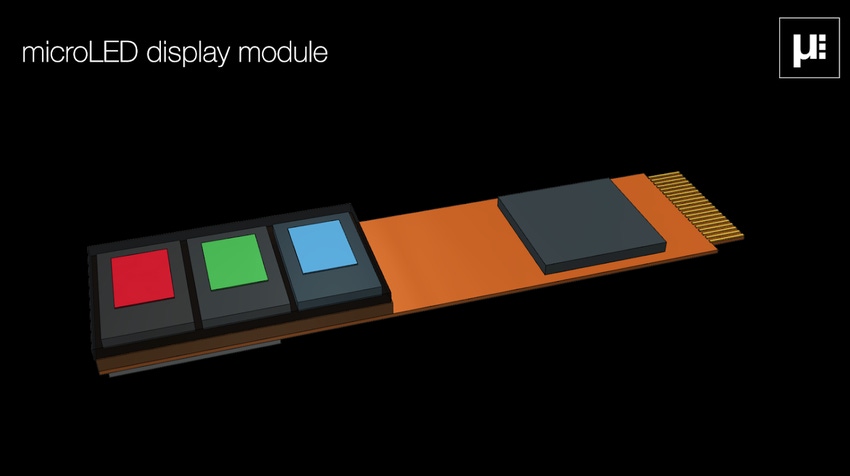

Joint partnership will develop mass producible, full-color microLED displays using quantum dot materials.

Augmented reality (AR) calls for new approaches to display technology, and two companies, QustomDot and MICLEDI Microdisplays, have agreed to a joint development program to address the growing demand for compact, energy-efficient microdisplays for AR applications.

Under the agreement, QustomDot, a color conversion developer for microLED displays and MICLEDI Microdisplays, a leading developer of microLED displays for Augmented Reality (AR) glasses, will demonstrate a full-color microLED integration in polychromatic pixel arrays. The developments are supported by Flanders Innovation and Entrepreneurship (VLAIO). The Flanders-based consortium enables development of technology for microdisplays with high-resolution and high-brightness.

The technology combines stable, RoHS-compliant Quantum Dot (QD) color conversion materials, a microLED architecture tailored for high-efficiency color conversion, and high-throughput QD transfer and patterning techniques on micron-sized pixels.

According to the companies, the two biggest challenges are brightness of the image against an outdoor sunlight environment and power consumption, which translates into larger or smaller batteries to power the brightness of the glasses. The underlying challenge, which lies at the root of consumer adoption of augmented reality glasses, is achieving these two goals at a manufacturing cost low enough to provide an attractive product and price to consumers.

The desired performance of microLED arrays for AR glasses is directly related to the wide variation in performance targets of the glasses themselves. Quantum dots, by their very nature, are less bright and lower resolution than intrinsic microLEDs, especially those with micro lenses to focus the light. The collaboration between QustomDot and MICLEDI Microdisplays is expected to produce single-chip RBG microLED arrays resulting in low manufacturing complexity and a smaller form factor than tri-panel microLED arrays can achieve in the near future. Smaller form and simpler packaging, resulting in lower cost for certain types of microLED arrays, will come out of this collaboration.

“New QD materials for color conversion are a game changer. Our patented method for producing RoHS-compliant QDs deliver high-quality and stable materials. This makes them effective for microLED applications, which will accelerate product development in this untapped market,” said Willem Walravens, CTO QustomDot, in a statement.

“Polychromatic arrays are an important development for microLED products. The manufacturing precision of MICLEDI’s 300mm microLED approach is a perfect enabler for highly efficient color conversion,” said Dr. Soeren Steudel, MICLEDI CTO, in a statement. “Our new pixel architecture has been optimized for high aperture (>60% aperture at a 3 µm pixel pitch) which is a key requisite to achieve a high brightness with quantum dots.”

The companies expect to bring products to sample into the market and then into mass production in the next 2 to 3 years.

About the Author(s)

You May Also Like