Mechanical Switches Solve Sprinkler Control Problem

July 11, 2012

Over the weekend I got a reminder about the value of mechanical switches in some human-machine interfaces. People cannot do everything, nor should they, through a display, touchscreen, and a few pushbuttons.

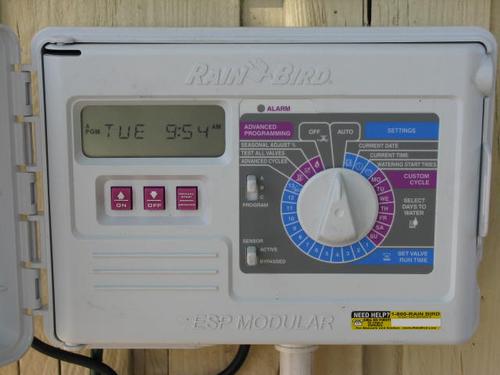

We have in-ground sprinklers that water our lawn in eight zones. Three other zones handle drip-irrigation lines to shrubs, flowers, and ground-cover plants. Several years ago a landscaper installed a commercial sprinkler controller that lets me set the time for the sprinklers to start a sequence, the length of irrigation time for each zone, and three possible "programs." The controller provides three pushbuttons, a rotary switch, and an LCD. I find that human interface annoying and limiting.

Most of the time the system runs through all 11 zones every few days. At times, though, I want to run a special sequence of, say, zones 3, 4, and 7 to water areas that look particularly dry. The next time I might need to water only zones 1, 2, and drip lines in zone 11. To run such sequences I must select one of the three programs, turn each of the 11 zones on or off by using the rotary switch, pushbuttons, and LCD, run the special sequence, and then return the program to its original state by again going through the zones, one by one. (I rarely vary the watering time for zones, so that's not an issue.)

It would have helped if the manufacturer had provided a set of switches so I could quickly and easily select a few zones and run through a cycle to water only those areas. At the end of the cycle I could change the switch settings so the next cycle would go through all or a few zones. But the controller doesn't provide that flexibility. Although the controller manufacturer has newer units, they still lack the capability to easily turn zones on or off temporarily without having to go through programming steps. An Internet search located many controllers, but all have the same type of interface and limits.

I thought about a design for my own controller that would offer all the "bells and whistles" needed, but after sketching a few ideas, creating a rough flow chart and list of software functions, and thinking about the time needed for a one-off project, I abandoned the idea. There had to be a simpler way to solve the problem.

Then a solution came in a flash -- intercept the valve-control signals that go from the controller to the individual water valves and insert an SPST switch for each signal. Then the controller can go through its regular cycle for all 11 zones, but the switches control the water valves that actually operate. This type of external retrofit solves the special-cycle problem and requires only an external box and switches. I can add it to the circuit without much work. I might include an LED for each zone so I can tell at a distance which valve has power. I have LEDs and switches on hand and just need a plastic case.

The controller manufacturer could have included this type of capability, or at least offered it as an add-on product. Simple mechanical switches triumphed over an overly complicated "simple" user interface.

Related posts:

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)