Injection Molding: The Mystery of the Melt Temperature

Current methods for measuring melt temperature during injection molding are often inconsistent or expensive. The Melt Temperature Measurement System promises to deliver precise, repeatable results in a low-cost package.

November 30, 2020

Fill speed, pack pressure, cooling rate, and melt temperature are the four critical process variables of injection molding that control the quality and consistency of molded parts. The first three variables are relatively easy to duplicate when lots or colors are changed or machines are switched. Not so with melt temperature, which can remain a mystery that few processors have the time, knowledge, or equipment to solve, according to Rich Bleck, a 48-year veteran of the plastics industry. He has developed a proprietary system that precisely measures the melt or purge temperature during the injection molding process. His company, Procon Training & Consulting LLC, has partnered with Schmit Prototypes to manufacture and market the Melt Temperature Measurement System (MTMS).

|

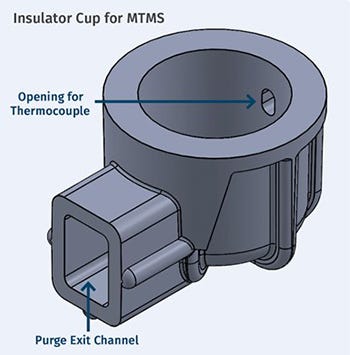

The material is maintained in a molten state in the insulator cup during the measurement process. |

Various methods are currently used to measure melt temperature, but all of them have drawbacks, says Bleck. “There is the standard purging of resin into a puddle and inserting a thermocouple probe, stirring the puddle, taking three shots, and calculating the average,” he explains. “This method has inconsistencies due to skinning of the polymer on the probe and human measurement errors. It also takes a significant amount of time, which fouls up a steady state process.”

Using infrared cameras to measure melt temperature can achieve good results but requires sophisticated equipment and adherence to a strict procedure. It also can be expensive and only measures the surface, adds Bleck.

“Other methods use an insulated cup to catch the purge and insert a thermocouple probe. This method has significant issues, such as the size of the thermocouple and the technique of the operator,” says Bleck. “It may require multiple shots if it is a small shot size. Therefore, rpm, back pressure, and residence time are not factored into the melt temperature. Moreover, all three of these methods are very difficult to use on small shot sizes,” says Bleck.

Precise melt temperature measurement made easy.

The MTMS method is based on an insulator cup that keeps the material in a molten state during the measurement process. It also precisely positions the thermocouple probe in the effective flow path. The process is shown in the embedded video. In addition to its low cost and ease of use, Bleck cites the following advantages compared with conventional technologies:

The ability to measure shot sizes under one ounce;

once the process has been stabilized, it takes only one shot to measure the melt temperature;

minimal downtime, generally under one minute;

excellent repeatability between operators.

The importance of complying with resin supplier recommendations for melt or process temperatures, which MTMS facilitates, cannot be overstated, according to Bleck. If the temperature is too high, the polymer will degrade; too low, and the part will be difficult to fill, pack out, and maintain a good appearance, explains Bleck. “Melt temperature influences the plastics viscosity or resistance to flow (thick or thin) and is critical in obtaining optimal part dimensional control. Consistent viscosity allows for repeatable filling of the mold with consistent cavity pressures. This correlates to less shrinkage variation and a tighter bell curve on normal production variations. Hence, molding with the same melt temperature generates higher quality parts from lot to lot and press to press,” says Bleck.

Don’t make the mistake of thinking the temperatures shown on the controller screens are actual, he cautions. “Those thermocouples are reading steel temperatures along the barrel, not melt temperatures.”

Bleck spent five years developing MTMS technology, which he describes as a “repeatable, safe, fast, accurate, and low-cost alternative to current methodologies.” It is now available to plastics processors. For more information, visit schmitprototypes.

About the Author(s)

You May Also Like