Inertia Mismatch: Fact or Fiction?

February 7, 2013

Servo systems may be direct-drive or geared systems. For geared systems, the choice of motor also involves a choice of gear ratio.

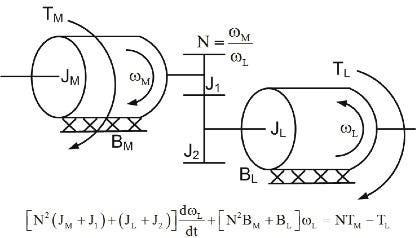

Figure 1 shows a motor connected to a load through an ideal (i.e., no friction, no backlash, and no compliance) gear train with gear ratio N. The equation of motion for this one-degree-of-freedom system is shown in terms of the load angular velocity. The inertia ratio is the ratio of the load inertia to the motor inertia, JL/JM. What is the optimum value of this ratio for a particular value of N?

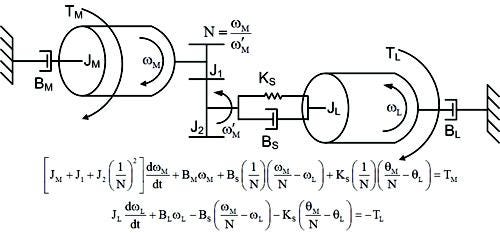

If we ignore the motor and load damping, BM and BL, respectively, and the load torque, TL, the inertia ratio that maximizes the power transferred from motor to load is N2, i.e., the reflected motor inertia equals the load inertia. When friction and load torques and system compliance (e.g., coupling or timing-belt compliance) are significant, the selection of an optimum inertia ratio is less straightforward. Figure 2 shows this more general case.

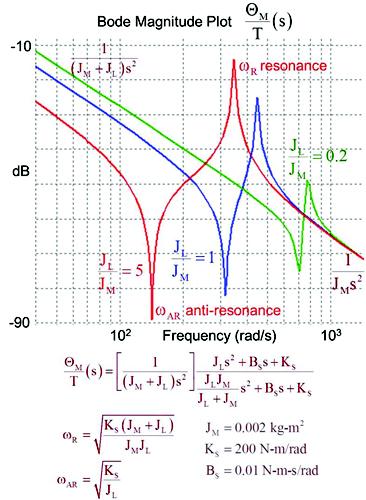

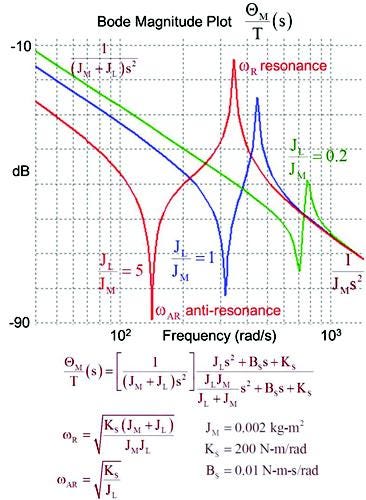

Why do deviations from the so-called ideal inertia ratio of N2, called inertia mismatch, particularly in compliantly coupled systems, often cause servo-system stability problems? This is a system question and to answer this question we must examine the frequency response plot for a compliantly coupled motor and load, as shown in Figure 3 (N = 1, BM = 0, BL = 0). The anti-resonance frequency ωAR always occurs before the resonance frequency ωR. At a low JL/JM ratio, the resonance and anti-resonance frequencies are close to each other at a high frequency. As JL/JM increases, both the anti-resonance and resonance frequency decrease, with the anti-resonance frequency decreasing at a faster rate. For a given JL, to increase the resonance frequency, either increase the shaft stiffness, KS, or decrease the motor inertia. As KS increases, both ωR and ωAR increase. The smaller the inertia ratio, the less compliance will affect the system.

All mechanical systems have compliance, and the choice of the inertia ratio and transmission ratio (e.g., gear, belt, or lead screw) and the design of the feedback control system are done based on a system analysis and not by trusting poorly defined rules of thumb.

Related posts:

About the Author(s)

You May Also Like