Improving Collaboration with Waveform Analysis Outside the Lab

Collaboration is more important than ever in modern engineering environments. Here's one way to promote it.

December 2, 2016

We’ve all heard the legends of famous inventors who sat solitary in their labs until the wee hours of the night until they came up with a stunning breakthrough. But the reality is that even the famous inventors of yore had to collaborate with others. For instance, Michael Faraday who discovered the basis for electric motors among other accomplishments, lacked math skills and had to collaborate with physicist Clerk Maxwell to develop equations to explain the relationship between electricity and magnetism.

In modern engineering environments, collaboration is more important than ever and becoming increasingly complex as engineers find themselves working with colleagues located in multiple locations and time zones around the world. Unfortunately, there’s little question that we’re wasting a lot of time due to inefficient collaboration. A recent survey commissioned by Planview and conducted by research firm Appleseed Partners found employees waste more than seven hours per week per person of productivity time because of collaboration issues, adding up to 350 hours or nearly nine weeks per year.

|

While this survey focused on project managers, chances are the numbers aren’t far off base for design engineers. One of the keys aspects of collaboration

is effective sharing and dissemination of information among the team or organizations. That information can range from simple to complex. It could be schedule-related. It could be updates to project risk assessments. It could be detailed design information conveyed by schematics or, later in the design cycle, it is likely to be data captured by an oscilloscope.

Effectively sharing scope information with team members, suppliers or customers requires both completeness of information and portability of information. In most cases, the two most common ways of sharing scope information fall short of meeting these requirements.

As an example, let’s say there’s a problem with a design. A component is not behaving as expected and the designer needs to communicate the problem with a supplier. The most common choice is a simple screen capture which can be dropped into a PowerPoint, annotated and then sent around via email.

Design Technologies. Learn more about electronics and security at ESC Silicon Valley, Dec. 6-8, 2016 in San Jose, Calif. Register here for the event, hosted by Design News ’ parent company, UBM.

Design Technologies. Learn more about electronics and security at ESC Silicon Valley, Dec. 6-8, 2016 in San Jose, Calif. Register here for the event, hosted by Design News ’ parent company, UBM.

While this approach does work, it often results in time-consuming back and forth email strings because information is not as complete as it needs to be. What if the screen capture doesn’t show a piece of information the supplier needs? What if they need to add a measurement to get a better understanding of what’s going on? Back and forth we go.

Another option would be to save the data as a reference file of some sort. Depending on your scope vendor of choice, you have a number of options, most of which are proprietary. If you go this route, you’ve traded one problem for another. The data file is complete but not portable. You’ve now restricted the supplier’s ability to easily use this data. They not only need to load it back into a scope to view it but that scope needs to be the same as yours.

To address these problems, a third and potentially much more effective option now appearing on the market is PC-based analysis software that essentially decouples the analysis function from the physical instrument. These tools typically can handle the wide range of waveform formats that are likely to originate from various oscilloscopes or simulation environments.

The major advantage of PC-based scope analysis tools, of course, is that users can share entire waveform records not just screen captures. This enables suppliers or other team members to see what led to a particular event or problem and to see the set-up used to make the measurements. Unlike a physical instrument, PC-based analysis tools are readily available and easily shared. Most suppliers of PC-based analysis tools will offer some sort of floating or transportable licensing options for occasional users.

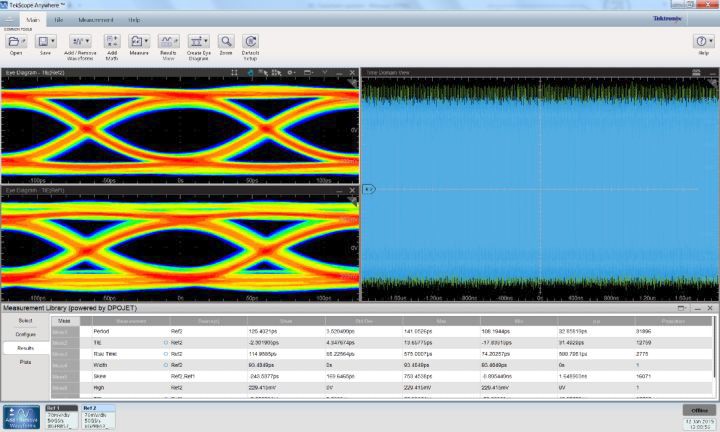

Among the more advanced capabilities to look for is a composite save/recall function to help collaborators quickly get started at the right place. For analysis in team environments, the tools can incorporate sizeable measurement libraries for parametric, jitter, and eye diagram analysis. They also offer visualizations with waveform and plot displays and interactions for zooming, cursors, and annotations along with math support for operands, FFT, and arbitrary filters.

A common issue that arises when taking lab measurements is correlation between instrumentation and simulation. The source of differences can often be related to differences in measurement algorithms. By allowing users to import multiple waveform formats from different sources, PC-based scope analysis tools can help address differences resulting from the use of differing analysis tools. For example, as shown in the image above, users can simultaneously compare the eye opening of a waveform captured in the lab vs. a simulated waveform or waveform captured on a different oscilloscope from a different vendor.

Collaboration most likely isn’t at the top of the list when organizations look for ways to improve electrical engineering productivity, but perhaps it should be. If your productivity and collaboration could use a boost, offline PC-based scope analysis software could be worth a closer look.

Mike Juliana is a product marketing manager responsible for Ethernet solutions. He has been with Tektronix since 1988 in a variety of engineering and management roles. He has a bachelor's degree in Electrical Engineering from Brigham Young University and a master's degree in Computer Engineering from Oregon State University. In his free time, you can find him hiking or skiing in the mountains of Oregon.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)