How Additive Manufacturing Is Making Injection Molding Cooler

April 29, 2015

Plastic part manufacturers are always looking for ways to reduce cycle time and get more productivity out of their injection molding machinery. One of the longstanding constraints in injection molding production has been cooling time. Removing parts from the mold before they have cooled induces warping or shrinking. But wait time works against productivity.

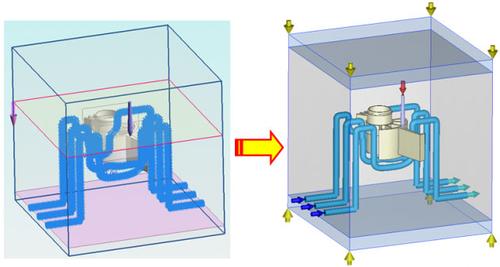

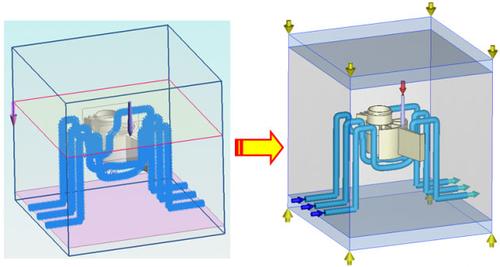

Another constraint has been cooling channels drilled straight through the metal blocks of injection molds using CNC machining. While coolant is passed through the channels to cool the mold and draw heat away from the part after it has been injected, the efficiency of that cooling process is limited by the conventional straight-line drilling that's used for the channels.

But if those cooling channels could more closely conform to the shape of the part, the cooling process could become more efficient and faster. According to Tober Sun, manager for the technical research division at software provider Moldex3D, a typical production cycle for a plastic part is 30 seconds to a minute, but cooling takes more than half of that cycle time.

Thus, he says conformal cooling has emerged as a practice, which is being aided by advances in additive manufacturing. With a conformal cooling channel design, the toolmaker can use an additive process to lay down the mold one layer at a time, fashioning the cooling channels along the way and curving them to any desired shape.

According to plastics consultant Robert A. Beard, "a typical cycle-time reduction range for a properly engineered, conformally cooled mold is 20% to 40%." Such savings can lead to much greater productivity, especially in high-volume plants producing millions of parts.

MORE FROM DESIGN NEWS: Injection Molding Adapts to a More Interconnected World

Many industry observers associate conformal cooling with laser sintering, in which a solid object is printed by melting metallic powder using lasers. Sun told Design News that he prefers the broader term "additive manufacturing," because of the widespread perception that sintered molds are not as strong as machined molds.

"It's not really sintering anymore. I prefer to call it remelting," as it produces a solid metal object, he said. Sun stresses that additive manufacturing technologies are now handling very strong and durable materials, such as stainless steel and titanium, which compete well with machined molds. "Strength is no longer an issue," he contended.

Sun recognizes that the added design effort and the use of additive technologies will increase the cost of mold development. But injection molds are expensive to start with, as they usually cost anywhere from $30,000 up to $1 million. The true economic concern shouldn't be the comparative cost of conformal molds versus traditional molds, Sun insists, but the trade-off between the added cost of the conformal mold versus the savings in cooling time on the production line. "The mold is quite unique and expensive, but you are using that single mold to make millions of parts. So it's important to increase the efficiency of that mold."

Moldex3D makes one of the simulation solutions that designers are using to create molds with conformal channels. The company's Moldex3D Designer solution includes a Cooling Channel Design (CCD) module.

Such applications aren't simple by any means, as cooling channel design is an optimization task with a multitude of factors to consider: the shape of the part; the temperature of the plastic; the speed of the coolant; and the thermal characteristics of the mold, the plastic, and the coolant -- not to mention the amount of cooling time the manufacturer is trying to shave off. CCD is said to allow the designer to enter a set of parameters and then generate an optimal conformal cooling design that can be edited and incorporated into the larger injection tooling design.

Al Bredenberg is a writer, analyst, consultant, and communicator. He writes about technology, design, innovation, management, and sustainable business, and specializes in investigating and explaining complex topics. He holds a master's degree in organization and management from Antioch University New England. He has served as an editor for print and online content and currently serves as senior analyst at the Institute for Innovation in Large Organizations.

Design engineers, New England's premier design and manufacturing event, Design & Manufacturing New England, will take place in Boston, May 6-7, 2015. A Design News event, Design & Manufacturing New England is your chance to meet qualified suppliers, get hands-on with the latest technologies, be informed, and expand your network. Learn more here.

About the Author(s)

You May Also Like