High Frequency Hexapod Testing

April 21, 2011

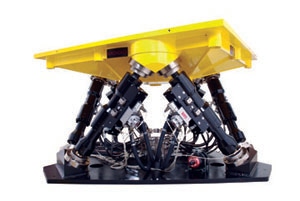

Controlrefinements to a six degree of freedom hydraulic hexapod used for automobiletesting and simulation is producing more versatile and expanded testingcapabilities forExovaCorp., aglobal, independent automotive testing facility. The hydraulic simulation tablefrom Moog Inc. simulates acceleration and displacement outputs, and reproduceskey data collected on proving grounds and other road/field surface events. Itoffers vector-based motion, and can perform translation and rotation functionsin conjunction with an expanded frequency range up to 100 Hz.

High Frequency Hexapod Testing_A |

"The system is similar to a flight simulatorthat leverages core motion control technologies in the areas of hydraulicvalves, hydraulic actuators and closed-loop control," says Tobe Ehmann, productapplication manager - simulation for Moog Inc. "The design goal is ahigh-performance system that provides customers in the test segment a devicethat offers higher frequencies, higher payloads and also vector motion."

Incorporating fatigue-rated hydrostatic servoactuators to deliver more than 14g of vertical acceleration to payloads beyond1,500 lb, Exova uses the hexapod simulation table for performing simulationtesting on various subassemblies or complete systems for automotive, light andheavy-duty truck, agricultural and military applications. Automotive testingincludes interior and exterior assemblies, seats, steering column assemblies,cooling module systems, truck and tractor cabs, and After Treatment Systems(ATS) for heavy-duty diesel applications.

Higher frequency provides an increasedcapability compared to normal simulation tables that range from 45 to 50 Hz.Steve Panter, operation manager at Exova, says that when the company doestesting analysis, a lot of damage occurs within the range from 50 to 80 Hz.With a regular simulation table, results are often filtered down to 40 Hz, soany damaging events beyond that point are not captured. The hexapod systemallows those events to be included in the scope of testing, and broadens thevalue of the testing process.

"A driving factor with running higherfrequency tests is the frame of reference," says Ehmann. "Tests run onstructural members of an automobile body frame, for example, typically see alow-frequency spectrum. But with engine testing, the frame of reference changesto a much higher frequency vibration spectrum. Capturing or replicating drivefiles from an on-engine component or engine coupling typically have a muchhigher frequency range. TheMoog simulation table enables tests on engine components above vibration levelsthat were achievable with traditional orthogonal systems."

High Motion and LoadTesting

The focus on highermotion performance is a competitive advantage for testing facilities, andultimately the end customers, as a way to deliver faster time to market andreduce costs. Increasing the frequency of the simulation table both expands thespeed and the effective range of tests.

"The testing that Exova provides is related to structural testingof individual components," says Panter. "The goal is to replicate the inputsthat a system or subsystem will actually see on an accelerated durability testcourse or in the real world. With every component mounted to the table thatprovides the six degrees of freedom, we put in all three-axis loads (X, Y andZ) along with pitch, yaw and roll."

Another area where the hydraulic hexapod offers a distinct advantageis the ability to handle much bigger payloads than any competing system on themarket. For example, Exova had one unique requirement for a Navy applicationwhere it would normally run tests using an ED shaker, but couldn't because ofthe size of the part. Since the Moog simulation table is able to run in eitheractuator or hexapod modes, the company was able to do an exact translation, oneaxis at a time, running a part that weighed 3,800 lb.

"The test ran in a frequency range from 4 to 17 Hz which couldn'thave been duplicated on an ED shaker because testing at less than 4 Hz ends upcreating stroke limits and, with the higher frequencies, the payloads were toohigh," says Panter. "The design of the valves and actuators on the hexapodallows the higher frequency compared to typical testing systems. Payloads areoften rated the same, but the system can never achieve the higher frequencytest criteria."

High Frequency Hexapod Testing_B |

Because the system uses vector motion rather than movingindividual axes in a single plane, Ehmann says results are more realistic andsimilar to motions a component under testing would experience in the realworld. In many orthogonal systems, multi-axis tests are implemented one planeat a time. The Moog system allows all of the testing to occur at once and, insome applications, the user is able to significantly reduce the amount oftesting time.

Upgrading theTried-and-True

While the six degree offreedom hexapod (aka Stewart platform) itself is not new, what's different nowis optimization of the controls using a closed-loop test controller anddifferent types of hydraulic valves at various flows and responses.

"The flow rates of the system have been optimized, which affectthe velocity and responsiveness, along with the gains in the control loopswhich ultimately affect the frequencies," says Ehmann. "Performance has beenfine-tuned, focusing on the payload and frequency response of the hydraulictest rig."

The orthogonal approach is a nested type system where theconfiguration is typically a plate, on top of a plate, on top of a plate.Systems typically use hydraulic actuation with each of the plates to create allthree vectors of motion. The table operator creates different types of motionfor testing manually by moving the three axes independently.

The biggest engineering challenge in developing the system waseliminating leakage with the hydraulic actuators. Moog was able to resolveinitial rod leakage issues experienced in the development process by optimizingthe smoothness of the rod, and working with seal vendors to ensure an optimalsealing arrangement.

The development of the system itself turned into an iterativeprocess working to get the correct match between loop gains, valve flows andvalve response. The process encompassed optimization of the mechanism and thereal-world process of making it work effectively as a system. But the key toits performance is the expanded flexibility that it brings to the testingprocess.

"The ability to run the system in two different modes allows thetable to do motions that are not typical of a normal MAST table without newfront end controls and drivers to enhance the controls," says Panter.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)