Decoding Procurement: How It Can Work as Design Engineering’s Ally

January 22, 2015

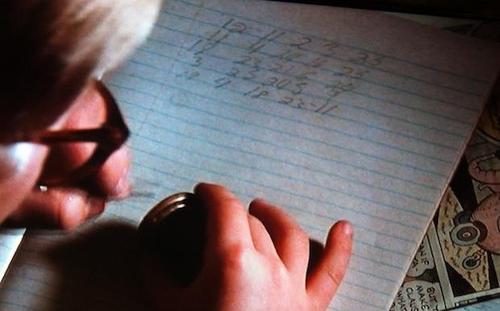

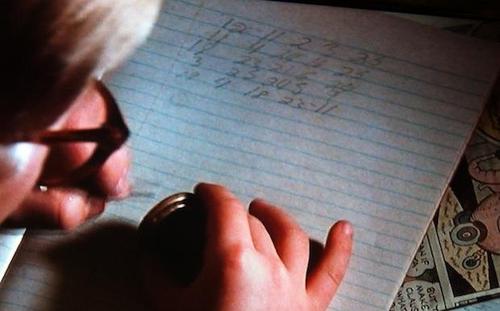

In the movie A Christmas Story, Ralphie famously longed for the decoder pin necessary to translate a secret message from the Little Orphan Annie radio program. Much to his disappointment, and after drinking an unthinkable amount of Ovaltine in order to collect the requisite labels, he deciphered the top-secret message as, "Be sure to drink your Ovaltine." What a letdown.

Not to be outdone, many of today's procurement organizations speak in what may seem like a cipher. After design engineers endure the taxing processes of spend analysis, spec rationalization, and supplier discovery, they often find that procurement and sourcing's ultimate message is no more than, "Be sure to count your pennies." This disappointment may leave an even worse taste in your mouth than Ovaltine.

Procurement actually means well. There is no question that procurement can do a better job of phrasing their questions or making connections between engineering's goals and the processes underway. And if you are using the right deciphering code, the result can live up to -- or surpass -- your expectations.

The role of the procurement function has changed significantly in recent years, as cost control and risk management mandates by the C-suite have put product engineering in procurement's purview. In the meantime, if engineering departments are willing to give procurement the benefit of the doubt, they'd be amazed at the things it can help engineering accomplish.

For instance ...

When procurement questions the incremental cost of a non-standard specification or requirement, it is looking for an assurance that a worthwhile value tradeoff is being made. Procurement has been conditioned to drive out excess costs wherever it finds them. The key is for engineering to help procurement see seemingly non-essential costs for their worth in creating competitive advantage. And, to be honest, if the enterprise didn't want to see waste driven out of the supply chain, the procurement team would be reassigned or eliminated.

The fact that procurement is on the organizational payroll serves as a reminder that each design element leading to additional costs requires a clear value proposition. Think of it as a healthy check-and-balance. After all, if you can't make the case to procurement, you don't have much of a chance with the executive team when it starts inquiring about the profitability of the design.

Here's another thought ...

Procurement did not fall off the outsourcing truck yesterday. Sourcing departments have been down that road and seen both wins and losses. Procurement knows what circumstances are required to have a successful third-party services agreement, and how to make sure that the intended benefits are delivered. So when procurement members ask about turnaround expectations, communication requirements, and the need for demand agility, they are not being naysayers.

If you turn your decoder pin to position "O," you'll see that while outsourcing is described as one approach, there are actually many variations when you get down to it. There are myriad locations, agreement structures, and risks to be mitigated. By working with procurement to determine what you need (and want) from the arrangement, the department can get down to business and put the right players to work for you.

And finally ...

Rather than waiting until all of the Ovaltine is gone to expect some kind of message from procurement, engineering and procurement should regularly engage each other along the way. This includes early in the design phase, during the definition of bills of materials, and at any point when information is requested from suppliers.

One thing that good procurement professionals are great at is analyzing constraints, figuring out which cost tradeoffs or non-standard design elements are worth fighting for, and which ones are unlikely to pay for themselves through increased demand or improved performance. Procurement may even be able to help you model out the design in a way that gives you the flexibility to play with it and continue to make changes before making a final decision.

Should working with procurement be as painful as drinking dozens of servings of Ovaltine? Absolutely not. Rest assured, procurement members are not speaking in code just to make your life more difficult. They do so because they are focused on how their discipline can help the organization achieve enterprise goals and the metrics that go with them. To paraphrase the Little Orphan Annie radio announcer, "Be sure to give procurement a chance."

Design engineers and professionals, the West Coast's most important design, innovation, and manufacturing event, Pacific Design & Manufacturing, is taking place in Anaheim, Feb. 10-12, 2015. A Design News event, Pacific Design & Manufacturing is your chance to meet qualified suppliers, get hands-on access to the latest technologies, be informed from a world-class conference program, and expand your network. (You might even meet a Design News editor.) Learn more about Pacific Design & Manufacturing here.

Kelly Barner is the co-owner of Buyers Meeting Point, an online resource for procurement and purchasing professionals. She has been an industry award-winning supply management practitioner and consultant, and is now an independent thought leader and author on procurement, sourcing, and purchasing. Kelly earned her MBA from Babson College.

About the Author(s)

You May Also Like