Oscilloscope Adds New Dimension to Motor-Drive Analysis

A new oscilloscope-based test system adds a unique dimension to the process of analyzing the dynamic performance of three-phase motors and drives.

May 3, 2016

Shown at the recent Embedded Systems Conference in Boston, the MDA800 Motor Drive Analyzer is targeted at research and development engineers who need to gather information that hasn’t been easily available up to now. “This gives you a rich view of total system behavior that you can’t get with a power analyzer,” said Ken Johnson, product architect for Teledyne LeCroy, which makes the new product.

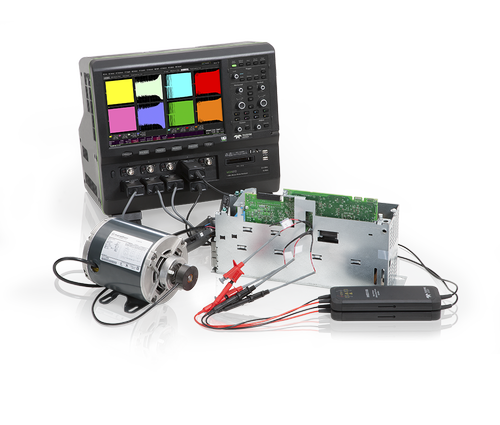

Teledyne LeCroy’s MDA800 uses an oscilloscope to analyze the dynamic performance of three-phase motors and drives.

(Source: Teledyne LeCroy)

The MDA800 is built atop an eight-channel, 12-bit, 1-GHz oscilloscope called the HDO8000. It includes hardware and software that enable it to do three-phase motor and drive analysis.

Because it’s scope-based, the unit is able to serve a distinct niche, Teledyne LeCroy says. Rather than analyzing performance under constant loads or speeds, as a conventional power analyzer would, it can characterize dynamic or peak instantaneous power events. “Our solution is essentially an oscilloscope that can capture events at fairly high speeds over long periods of time,” Johnson told Design News. “It’s for anybody who’s trying to understand dynamic or worst-case events.”

The unit is targeted at engineers who are designing motors, drives, and controls for industrial automation systems, variable-speed HVAC systems, electric turbochargers, electric bikes, hybrid cars, forklifts, and just about anything else that employs an electric powertrain. In one case, he said, the system was used by a supplier who wanted to study snow loads on windshield wiper motors.

READ MORE ABOUT TEST AND MEASUREMENT:

Johnson said the new technology is especially well-suited for research and development engineers, as opposed to product validation engineers. Power analyzers, he said, are more accurate for the constant load and speed measurements commonly used in validation. But the oscilloscope-based technique opens up new possibilities outside that realm.

“For a long time, R&D engineers have been stuck trying to make power analyzers work for them,” Johnson said. “But power analyzers were never designed for their applications.”

Using an oscilloscope, however, changes that. “You can’t get the same results if you use a scope and a power analyzer side-by-side,” Johnson said. “But you get a lot of new capabilities when you combine the two into one instrument.”

Keep up to date with advances in embedded systems by joining our ESC community.

Senior technical editor Chuck Murray has been writing about technology for 32 years. He joined Design News in 1987, and has covered electronics, automation, fluid power, and autos.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)