Big Data and Cloud Computing Have Moved into Design 26832

Design engineers are using big data to gather product usage information from the field and circulate it into design decisions. Much of that data is now processed in the cloud.

September 20, 2016

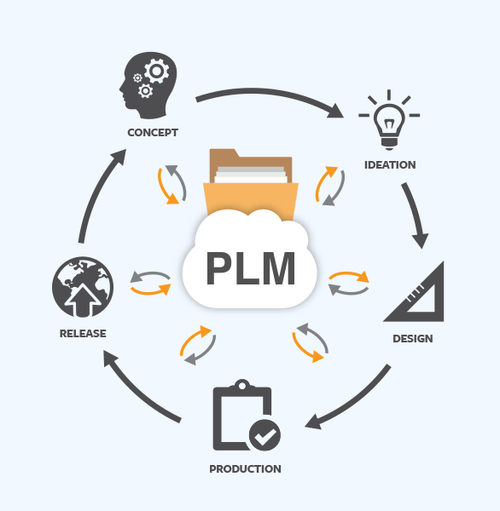

Big data is finding its way into the design process. Often it comes in the form of taking data from the manufacturing process while also gathering data from the field where end users are interacting with the finished product. When manufacturability and user experience inform the design process, you get improved products designed to be built more efficiently.

(Source: Arena Solutions)

We have a new name for the function of bringing this data into the design process: lifecycle analytics. “The data comes together in lifecycle analytics. These analytics are done at every stage of the product lifecycle,” said Bill Boswell, senior director of cloud services at Siemens PLM. “By using simulation and predictive analytics, you can understand how the design of the products predicts what’s going to happen with the product in manufacturing and in the field.”

Gathering Plant and Field Data

Plant analytics feed manufacturing information back to the design process. “You have plant analytics where you produce data by simulating how the plant is going to perform,” said Boswell. “When the plant is built, you collect tremendous amounts of data on how the plant is performing, including asset performance, predictive maintenance, and machine data.” Ultimately, plant data can help the design team create a product that moves efficiently through manufacturing.

Analyzing product performance issues with Omneo big-data analytics from Siemens PLM. (Source: Siemens PLM)

The last step in the lifecycle analytics is bringing data from the field back to design. “You add the product performance analytics and intelligence. That’s where you bring together all of the data showing how it performs in the field,” said Boswell. “That data includes call center data and warrantee information. You collect all that data to close the loop.”

Processing the Analytics in the Cloud

Lifecycle analytics requires data gathered from each stage in the life of a product and feeding it back to the design and manufacturing teams. That data crunching requires significant processing power. “Some of that loop-closing happens in the cloud. Plant analytics and product performance analytics take place in the cloud,” said Boswell. “You get all the infrastructure benefits from the cloud. It would be costly to do it on premises. You wouldn’t have enough processing power and memory.”

Owning the processing servers yourself can be more expensive than renting them. It’s simply too hard to judge how much you need. “Whenever you buy hardware yourself, it’s a large capital investment and you may overshoot or undershoot on the capacity and the people needed to run those servers,” said Boswell. “You can offload that mundane work that’s not key to your business. You don’t have to maintain servers in order to make the data available.”

Not only is it hit and miss how much equipment you’ll need for analytics, you won’t need the capability continually. “There’s scalability, speed, and availability with cloud services. These are resources you’re not using all the time,” said Boswell. “With the cloud providers, you can access it anywhere and access it when you need it. You can access it from anywhere in the world.”

Building a Car with Big Data

Big data is moving into the design process slowly. One industry that is responding positively is automotive. They’re not a stranger to using manufacturing data to help the design team boost the manufacturability of cars. Now they’re taking the next step of flushing user data into design. “Designers and engineers are just beginning to tap into the promise of big data for design. There’s already a great deal of data available on issues like product performance, user experience, and interaction with other products,” said Steve Chalgren, chief strategy officer at Arena Solutions. “Cars generate tons of user information. Companies like Tesla are taking advantage of that data to examine how drivers behave while behind the wheel in the real world. They get to see how the car performs under a variety of specific conditions.”

While user data can be valuable in the design process, it can also be used to improve an existing car that’s out on the road. “Tesla can then use the field data not only to improve its next vehicle, but also to send improvements via a firmware upgrade to current cars on the road,” said Chalgren. “For example, Tesla discovered that customers were inadvertently closing the trunk and all doors when the key fob in their pocket was accidentally depressed. To solve this issue, Tesla added an option for customers to turn the close-all-doors function off.”

READ MORE ARTICLES ON BIG DATA:

The big data coming from user experience can be interpreted to go beyond simply improving an existing product. It can be used to create new features or entirely new products. Much of that user data is now coming from connected products. “As IoT continues to connect a growing number of devices, designers will have even more data at their fingertips as they make design decisions,” said Chalgren. “Imagine a coffeemaker company that discovers a significant percentage of its customers are using its products in colder than normal environments, like a garage or a workshop. With this insight, designers could add a ‘garage’ setting that optimizes coffee making for that scenario to better serve that market niche.”

Making Big Data Easy

One of the challenges of using big data effectively is making sure those receiving the data can utilize it effectively. “Engineers are interested in big data for vehicle test info, for flight info, or data streaming from devices connected to the Internet, but it’s scattered and messy. They hear about the machine learning tool and they hear about deep learning, but they lack the expertise,” said Paul Pilotte, technical marketing manager at MathWorks. Solving this challenge can be a matter of training the design team to use the data effectively or making the data itself easy to use. “We’re trying to make the task of working with large data easier by breaking it into steps and workflow. We try to make it so the user can focus on being the designer. We make the process of working with large data easy.”

Bringing the Field Data Home

Another use of big data is applying it to equipment out in the field. If the data flow is sufficient, you can bring automation efficiencies to field-deployed equipment. “We work with off-highway vehicles from companies like Caterpillar. They want to use data to increase the uptime of their instruments, such as maximizing the uptime earth moving equipment,” said Pilotte. “They’re looking for data to help get to 80% uptime. By doing data analytics, they can predict when an engine in the field needs service. They use the data to better manage their supply chain.”

The energy industry is starting to use big data to optimize production. The data can be used to balance demand and capacity efficiently “Energy produces use big data to analyze energy generation in order to decide what to turn on to meet demand,” said Pilotte. “A person makes the final decisions, but an application gives them recommendations on which power generation source to turn on.”

Rob Spiegel has covered automation and control for 15 years, 12 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years he was owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like