Why Product Testing and Certification Really Matters

Do you ever think about all those marks and logos on electronic equipment? You should; they’re your assurance of product quality.

|

Quality-built home and industrial electronic devices have marks indicating that they have passed a variety of tests. The UL mark shown here indicates extensive evaluation and testing. (Image source: AutomationDirect) |

These days, we really don’t concern ourselves with questions around product safety all that often. Our homes and plants are full of electronic equipment and, under normal circumstances, we don’t worry about a refrigerator, computer, or electric motor causing a fire. We take it for granted that these products are built well and tested to ensure safe performance because most of them are.

At least this was the working assumption. But things are changing for the worse with some components—particularly for industrial use.

For the last 20 years and more, the bulk of the electrical components used in industrial facilities have come from companies that are known for their reliability and quality—much of which is assured through careful product design and thorough testing. Users might assume this is the case for all electrical components. Unfortunately, it isn’t.

What happens when inferior products are selected—either unknowingly or as a means to reduce cost? This type of situation is happening more often in the world of manufacturing because of both the growing interest in devices from the Maker community and the growing ease of purchasing inexpensive electronic components from no-name suppliers.

Understanding Quality Differentiators

Not all products are tested according to any government standards because testing is expensive and requires more sophisticated circuit design.

For someone working on a basic industrial project and needing a standard electronic automation device, there are many potential suppliers with a wide range of prices. Some searching on eBay can turn up unbranded units that cost barely one-quarter the price of even a high-value supplier, with other name brand units offered at far higher prices.

We’ll assume the un-branded unit works, but it will likely have few if any marks showing it has passed any certifications or tests. The customer in this case has no assurance that the unit has ever been checked for any type of manufacturing quality outside of powering up correctly. The more expensive choices will undoubtedly come with an assortment of testing marks, such as Underwriter’s Laboratories (UL), Conformité Européene (CE), Canadian Standards Association (CSA), and possibly others determined by the country of origin and intended markets.

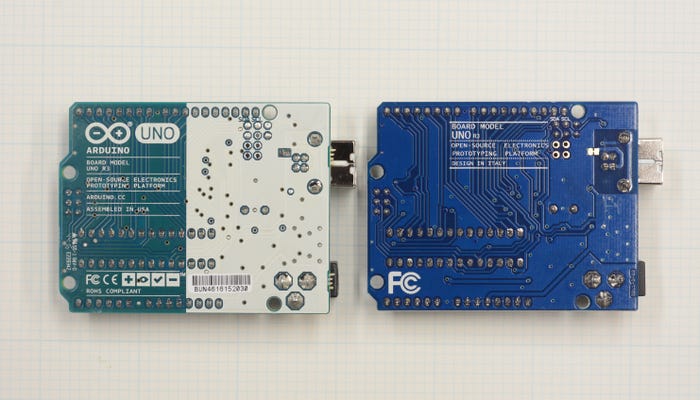

Similarly, someone wanting to use “maker” devices in a project has to be careful as to the source of the products. For example, the basic Arduino UNO, if made by the Arduino company, is provided with the CE and US Federal Communications Commission (FCC) marks. Additionally, it is ROHS compliant. These together designate that it meets the most basic requirements for levels of potentially hazardous chemical content, such as lead and cadmium—necessary for legal sale in the EU countries. The FCC mark indicates that it doesn’t cause excessive amounts of radio frequency interference (RFI).

|

Two functionally equivalent “Uno” boards, one from Arduino (left) and the other a clone, do not carry the same certifications. (Image source: AutomationDirect) |

Why Testing Matters

Those are fine as far as they go, but they don’t mean nearly as much as the kind of analysis and testing done by a nationally recognized testing laboratory (NRTL) such as UL. Moreover, it only applies to products actually made by Arduino. The bigger problem is that an equivalent board can be purchased from multiple manufacturers because the UNO design is open source. Anyone can make and sell a functionally equivalent board. It may operate exactly as it should, but it may not have any certifications at all. Let the buyer beware.

Product testing and certifications do not create quality, but they ensure a product is designed and manufactured with quality as a primary objective. Testing always requires using some standard as the yardstick (see table). For example, making sure a PLC can operate without getting excessively hot can be examined under IEC 61131-2. It covers more performance areas and goes into much greater detail. Basically, it defines circumstances of normal operation, the potential amount of time involved, and what temperature qualifies as excessive. The more complex the standard, the more complex the testing.

Standards may be imposed externally or internally. Manufacturing a product so it can carry the UL mark means it has to be tested to the relevant UL standard, verified by UL. In other cases, another lab certified by the standard-issuing organization can perform the test, but it can’t be done by the manufacturer. On the other hand, a manufacturer may perform its own tests. It can follow an existing standard, such as a MIL-STD, and say that the testing has been carried out in conformance with the standard.

RELATED ARTICLES:

The actual testing process pushes the product to any limits spelled out in the standard. If the standard requires it to survive a drop of 15 feet to a concrete floor, it will be dropped 15 feet to a concrete floor. If a switch has to be capable of surviving 50,000 cycles, it will be switched 50,000 times. Testing labs take these things very literally.

If an existing standard is not available or doesn’t pertain to the product as desired, a company can impose its own standard on a product. For example, let’s say it wants to advertise a new device designed for use in cold climates, able to perform when it is -40 degrees fahrenheit. The manufacturer may hire an external testing lab to carry out the test, but it may do it internally because it is an in-house standard. It will write its own procedure saying the unit must be placed in a freezer at -42 degrees for 24 hours before powering up, etc. The objective is figuring out a way to prove the point being claimed in a repeatable and documentable manner. Prospective purchasers can decide if they accept its validity or not.

|

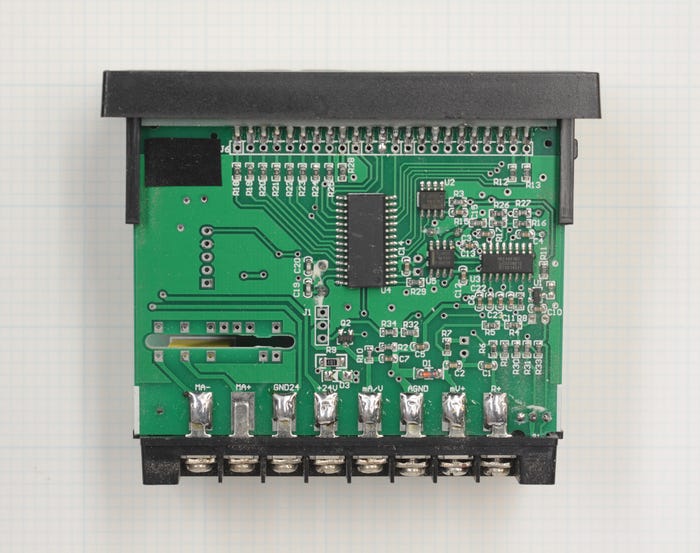

Shown are the internals of an unbranded, uncertified temperature display. It carries no marks at all, so there is no assurance it was designed well, uses quality components, or was assembled properly. For example, the MA+ connection at the lower left does not appear to be soldered, and the adjacent connections are hand soldered and inconsistent. (Image source: AutomationDirect) |

What Standards Include

Standards go well beyond simply describing testing procedures. Testing is certainly part of the process, but it goes much deeper to include how the product is designed and manufactured. A new product going through initial evaluation by an NRTL like UL will need to be studied in great detail. The first step is deciding which standards might apply for the type of product and its applications. Once established, the examiners begin looking for a variety of characteristics, including but not limited to:

If the components are appropriate for the application and procured from reliable suppliers. UL maintains lists of recognized suppliers of individual components that are considered acceptable. Those not on the list have to be tested.

If the circuit board and internal component layouts ensure conductors and board traces are wide enough for expected current levels, components have sufficient space between them, internal spaces allow heat dissipation, etc.

If the power supply is stable and capable of delivering sufficient current for all operating conditions without creating excessive RFI or heat.

If the design and construction files detailing the thought processes used for overall configuration, component selection, and assembly demonstrate correct thinking and analysis.

The list could go on at great length. Suffice it to say there are many elements typically entering into the discussion that are dictated by the nature of the product and its applications.

How Much Testing is Enough?

Standards issuers and testing organizations used for industrial electronic components and devices: |

|

ABS—American Bureau of Shipping |

ANSI—American National Standards Institute |

ATEX—Atmosphères Explosibles EU Directive |

Baseefa—British Approval Service for |

CCC—China Compulsory Certificate |

CE—Conformité Européene |

CGMP—Current Good Manufacturing Practices, US FDA |

CSA—Canadian Standards Association |

DIN—Deutsches Institut für Normung |

Most people who explore this topic in any depth are astonished by the number of testing organizations around the world and the mind-boggling number of standards. These stem from the days before globalization, when most industrial countries had their own locally manufactured products. Circuit breakers made in Germany were used there as well, and their own NRTL networks grew up to service those producers and users. The same thing happened in most other industrially advanced countries.

Nowadays, products can be produced and used anywhere, but the national concept of NRTLs persists. To a large extent, a user in Germany still has to have products tested and certified locally, but this is beginning to break down. For example, the CE mark in Europe applies to all the EU countries. Similarly, UL can do one test that applies equally in Canada and the US, but these are still exceptions to the larger regional rules.

Consequently, an automation product manufacturer has to launch a testing program for every major country. This creates a lot of duplicated effort, but at least most countries have relatively similar testing criteria. There are differences from country to country and some are stricter than others. But a truly well-designed and manufactured product can pass most examinations. Nonetheless, paying for all that testing can run up costs into the six figures and delay introduction of a product for months.

To further complicate matters, NRTLs usually insist on testing actual production models of a product rather than prototypes. This means a manufacturer has to gear up and produce months before they can have the necessary marks applied. This also adds cost.

The number of certifications required by a given customer will depend on a variety of factors. Some are regionally based and required by law. Specific types of plants—particularly those with hazardous environments, such as oil refining or chemical manufacturing—may have requirements outlined by a regulatory agency or industry group. Similarly, an insurance provider can impose minimum requirements needed to keep policies in force.

A Means, not an End

Product designers who know their efforts will be dissected under a microscope by a dispassionate evaluator realize they can’t cut corners. Everything has to be executed correctly at every phase of the process. Test and certification are simply a verification of the correct process. Passing the test is important, but not as important as a desire to create and build quality products.

Bill Dehner is a technical marketing engineer for AutomationDirect. He holds a bachelor’s degree in electrical engineering with an associate’s degree in avionics from the USAF. He has spent the majority of his 14-year engineering career designing and installing industrial control systems for the oil and gas, power, and package handling industries.

Tim Dunn is a design engineer for Host Engineering. He holds a bachelor’s degree in electrical engineering from West Virginia University. He has worked as a reliability and design engineer for a variety of companies, including Siemens and Texas Instruments. At Host Engineering, is responsible for design, development, testing, and certifications of many PLC product lines for AutomationDirect.

About the Author(s)

You May Also Like